|

|||

|

|

|||

|

Page Title:

INSTALLATION OF CAMSHAFT REAR BEARING PLUG, CRANKSHAFT REAR OIL SEAL HOUSING, AND FLYWHEEL HOUSING |

|

||

| ||||||||||

|

|

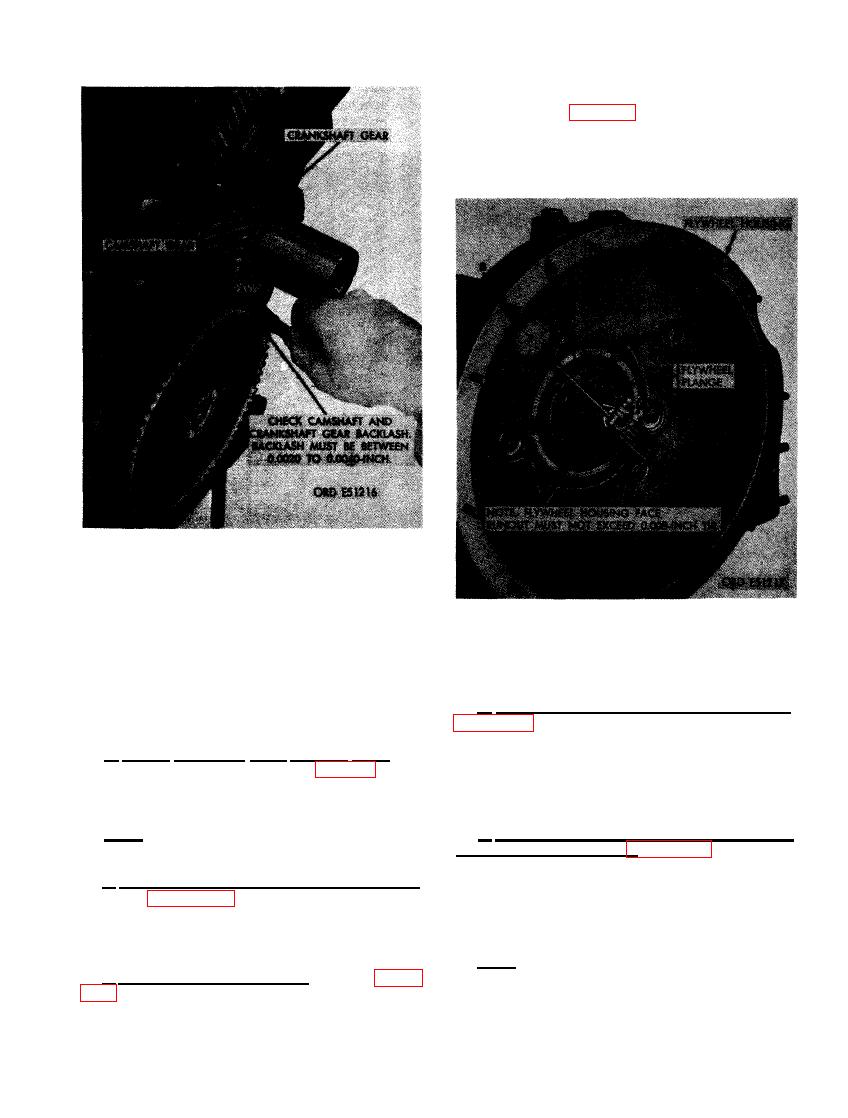

to install flywheel housing. A new flywheel

housing gasket (fig. 300) must be properly

positioned before installing flywheel housing.

Tighten flywheel housing nuts to a torque of

550-600 pound inches.

CRANKSHAFT GEAR BACKLASH USING

A FEELER GAGE.

FACE RUNOUT USING DIAL INDICATOR.

BEARING PLUG, CRANKSHAFT REAR

OIL SEAL HOUSING, AND FLYWHEEL

HOUSING

d. Check Flywheel Housing Face Runout.

shaft flywheel "flange so indicator point rests

a. Install Camshaft Rear Bearing Plug. In-

on the flywheel housing mounting face as shown.

stall camshaft rear bearing plug (fig. 312) and

(B) Set indicator on zero reading ("0"). (C)

Rotate crankshaft 360 degrees pushing toward

tap with a hammer to expand plug.

front of engine and check runout.

Note. Lubricate crankshaft hub and oil seal

e. Check Flywheel Housing Inside Rim for

Out-of-Round Condition. Figure 476 . (A) Mount

before installation.

dial indicator on crankshaft flywheel flange so

indicator point rests on inside rim of flywheel

b. Install Crankshaft Rear Oil Seal Housing.

housing as shown. (B) Set indicator to zero

Refer to figure 300 and reverse the sequence

reading ("O"). (C) Rotate crankshaft 360 degrees

of illustrations and instructions to install the

and check out- of- round.

crankshaft rear oil seal housing. Use a new

rear oil seal housing gasket.

Note. Replace flywheel housing when out-of-

c. Install Flywheel Housing. Refer to figure

round not within limits specified and recheck

out- of- round condition.

303

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |