|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. Clutch Cover. Replace the clutch cover

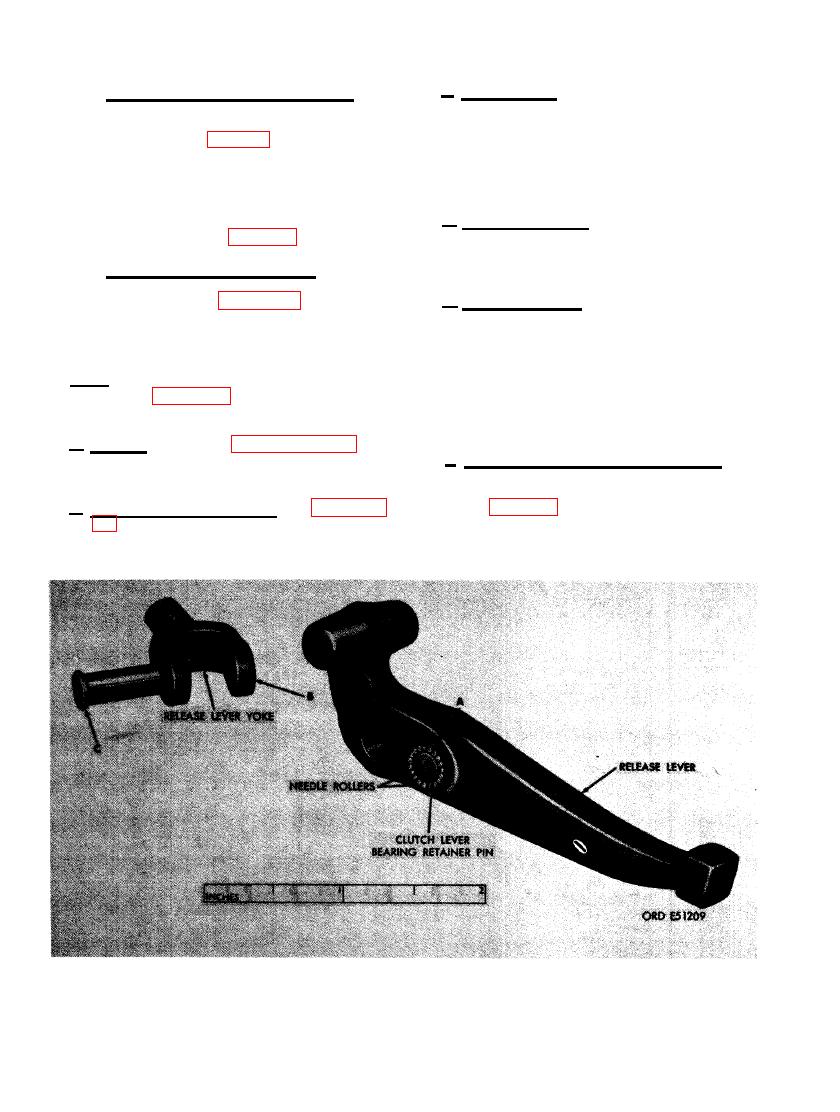

(4) Release levers and needle rollers. In-

(B-2) when cracked or warped. Repair minor

thread damage using a used tap. Replace the

against limits specified in repair and re-

clutch cover when screw holes are elongated

build standards (par. 298). Inspect re-

or warped. Replace the clutch cover when

lease levers for cracks and 152 bearing

rollers (B- l-b) for roughness and wear.

pressure spring seats are cracked or contain

indentations that will affect spring tension.

Inspect the four release lever pins (B-

I-a) and the four yoke pins (B- l-d)

d. Pressure Springs. Replace the pressure

against limits specified in repair and

springs (B-6) when distorted, cracked, or in a

rebuild standards (par. 298).

set condition. Replace any pressure springs that

do not have the correct free length.

(5) Driven member assembly. Inspect

driven member assembly following in-

structions for figure '91, excluding

e. Pressure Plate. Replace the pressure

plate (B-1-c) when cracked, warped, or when

step C.

the pressure plate clutch facing surface is

burned or scored beyond a 1/16-inch resur-

250. REPAIR

facing limit. Regrind a scored or slightly

cracked pressure plate using a surface grinder.

Note. The key letters shown below in paren-

theses refer to figure 456 except where other-

Do not grind surface more than 1/16-inch to

achieve a good surface. If more grinding is

wise indicated.

required, replace the pressure Plate.

a. General. Refer to paragraph 154 for

f. Release Levers and Needle Rollers. Re-

general repair instructions. Special repair in-

place any release levers (B-1-e) that do not

structions are listed below.

meet limits specified in repair and rebuild

standards (par. 298). Replace worn or damaged

b. Driven Member Assembly. Refer to para-

needle rollers in sets only. Replace worn re-

graph 67b and c for repair of the driven mem-

lease lever and yoke pins.

ber assembly (A).

YOKE USING BEARING RETAINING PIN.

292

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |