|

|||

|

|

|||

|

Page Title:

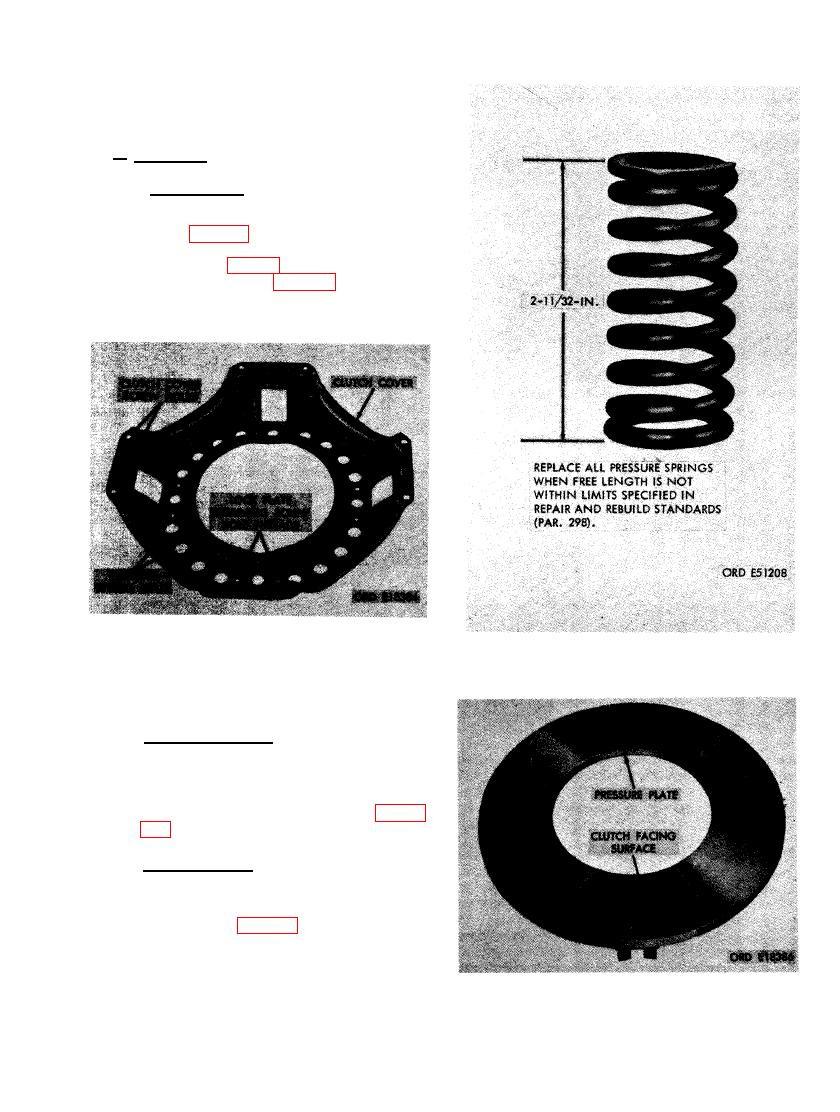

FIGURE 457. INSPECTING CLUTCH COVER PRESSURE SPRING SEATS AND SCREW HOLES |

|

||

| ||||||||||

|

|

a wire brush. Clean splines of hub and ring

assembly (A- 2) with cloth soaked in dry- cleaning

solvent or mineral spirits paint thinner.

b. Inspection.

(1) Clutch cover. Inspect the clutch cover

(B-2) for cracks and distorted mounting

flanges. Inspect clutch cover screw

holes (fig. 457) for elongation and the

lock plate retaining screw hole threads

for damage (fig. 457). Inspect the pres-

sure spring seats (fig. 457) for cracks

and indentations.

PRESSURE SPRING SEATS AND SCREW

PRESSURE SPRING.

HOLES.

(2) Pressure springs. Inspect the 16 pres-

sure springs (B- 6) for distorted and set

condition. Check free length of each

pressure spring using a height gage.

Free length of pressure springs should

be 2-11/32-inches as shown in figure

(3) Pressure plate. Inspect pressure plate

(B-1-c) for cracks and possible warp-

age, caused by severe heat due to

clutch slippage. Inspect the clutch fac-

ing surface (fig. 459) for deep scores

and rough surface. Replace pressure

plate clutch facing surface as directed

in paragraph:, below, when scores are

not deep and slight surface cracks are

evident.

CLUTCH FACING SURFACE.

291

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |