|

|||

|

|

|||

|

Page Title:

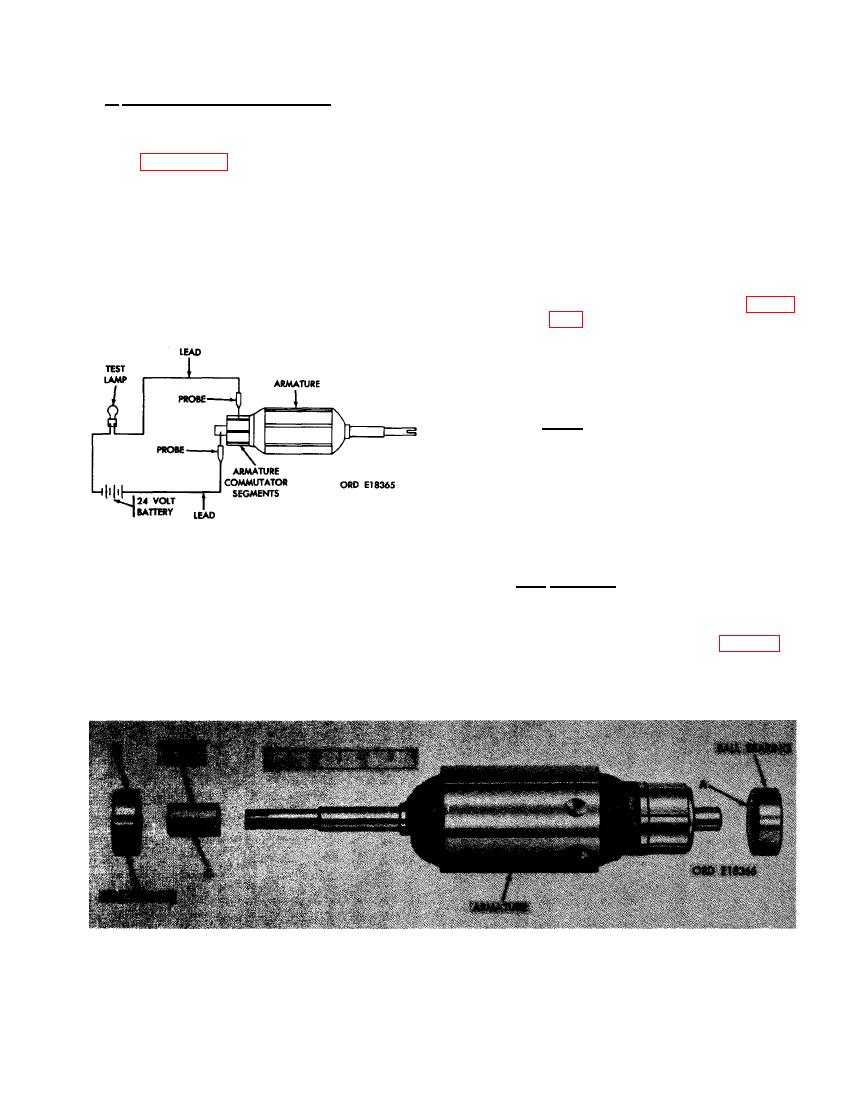

FIGURE 439. REMOVING OR INSTALLING ARMATURE BALL BEARINGS. |

|

||

| ||||||||||

|

|

worn excessively, replace armature.

e. Armature and Ball Bearings.

Turning down armature and under-

cutting mica is not recommended when

(1) Test armature for grounds. Test the

commutator is damaged. Clean the in-

armature (UU) for grounds as shown in

sulation between commutator bars by

carefully running a sharp knife blade

and contact one lead to end of armature

between the bars. Cleaning grooves

shaft. Touch each commutator bar in

will remove any possible brush carbon

turn with the other lead. When test lamp

or metal filings which would possibly

lights, as one individual bar is connected,

short out bars. Remove two ball bear-

a short circuit exists in the armature in-

ings (CC) and spacer (TT), to replace

sulation between armature shaft and

a damaged or defective armature.

commutator bar. Replace armature

when bars are short- circuited.

(b) Remove ball bearings as follows. Fig-

ure 439. (A) Remove front ball bearing

using a suitable bearing puller. (B)

Remove rear ball bearing using a suit-

able bearing puller. (C) Remove rear

ball bearing spacer.

Note. Install new ball bearings by

pushing them onto armature shaft, by

hand, until tight against shoulder on

shaft. If necessary, use a small hollow

tube, with inside diameter a little

larger than armature shaft diameter,

to butt against ball. bearing inner race

to tap bearings into position.

GROUNDS USING TEST LAMP.

(3) Ball bearings. Inspect the ball bearing

(CC) on each end of armature shaft for

(2) Check armature commutator bar and

roughness or uneven rolling action.

clean mica insulation.

When ball bearings are unserviceable,

replace both ball bearings (fig. 439).

(a) Check brush contact area on commu-

tator bars for excessive wear. When

277

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |