|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

sandpaper and remove all traces of dust with

compressed air.

Caution: Do not spin ball bearings (CC) with

compressed air or attempt cleaning them with

dry- cleaning solvent. Bearings are prelubri-

cated and sealed. Refer to TM 9-214 for care

and maintenance of ball bearings.

c. Brushes. Clean brushes (EE) with a clean,

dry- cloth only. Do not permit dry-cleaning sol-

vent to contact the brushes.

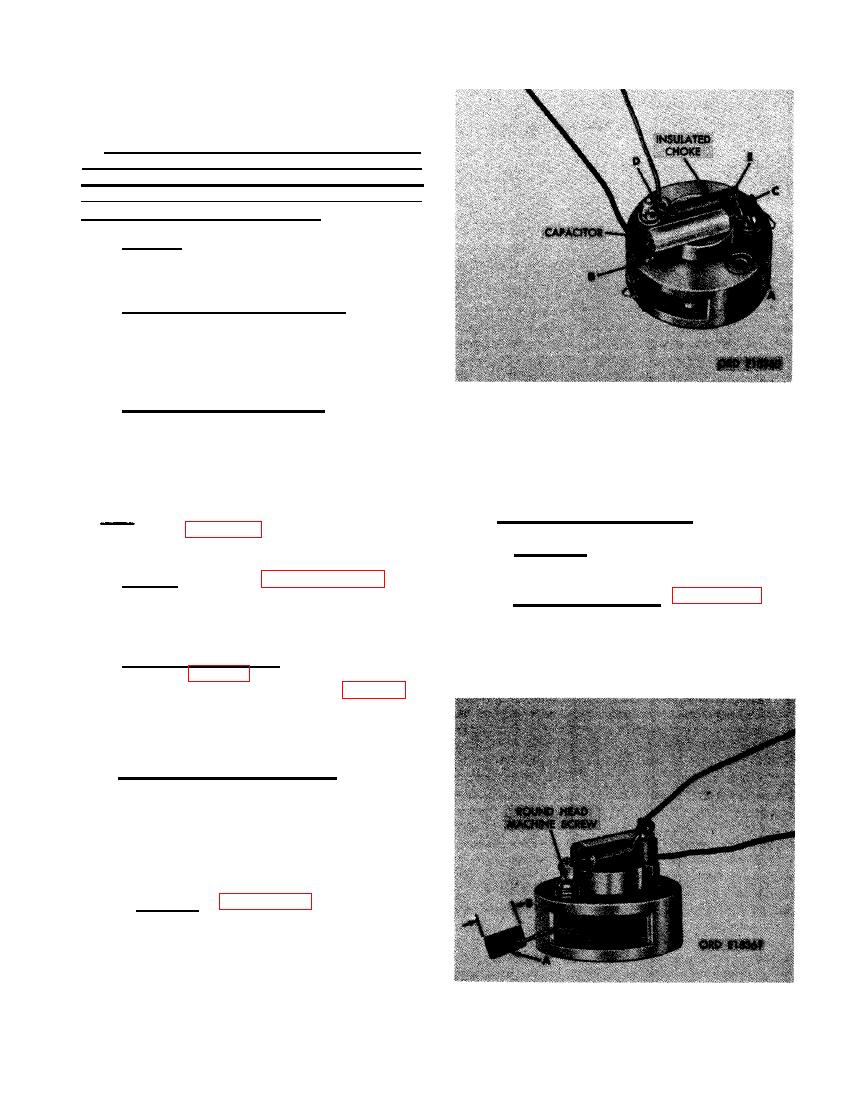

d. Insulated Choke and Capacitor. Wipe the

insulated choke (L) and capacitor (M) with a

clean, dry cloth. Do not allow dry-cleaning

solvent to contact the insulated choke and

capacitor.

e. Brush Holder and Insulator. Clean brush

holder (W) and insulator (V) with a cloth

dampened with dry- cleaning solvent. Dry thor-

CAPACITOR AND INSULATED CHOKE.

oughly with compressed air.

from terminal. (E) Remove insulated

choke and red wire.

d. Brushes and Brush Springs.

Note. The key letters shown below in paren-

theses refer to figure 431 except where other-

wise indicated.

(1) Inspection. Inspect brushes (EE) and

brush springs (FF) for cracks or breaks.

a. General. Refer to paragraphs 153 and

154 for general inspection and repair instruc-

(2) Check brush length. Figure 434. (A)

tions. Special inspection and repair instructions

Pull brushes out of brush holders.

are listed in paragraphs b through f below.

(B) Measure brush length. New brushes

--

are 3/8- inch long. Serviceable brushes

b. Relief Valve Housing. Inspect the relief

should be at least 5/16-inch long.

valve ball (K, fig. 432) and the ball seating

area in the relief valve housing (H, fig. 432)

for scores, scratches, and wear patterns. Re-

place parts when any of the above conditions

exist.

c. Insulated Choke and Capacitor.

(1) Inspection. Inspect the insulated choke

and capacitor (M) for frayed or

cracked insulation. Test the insulated

choke for continuity using a continuity

tester. Remove either if defective.

(2) Removal. Figure 433. (A) Unsolder

capacitor and insulated choke leads

from terminal. (B) Unsolder remaining

capacitor lead and black wire lead from

terminal. (C) Remove capacitor and

black wire. (D) Unsolder remaining in-

sulated choke lead and red wire lead

275

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |