|

|||

|

|

|||

|

Page Title:

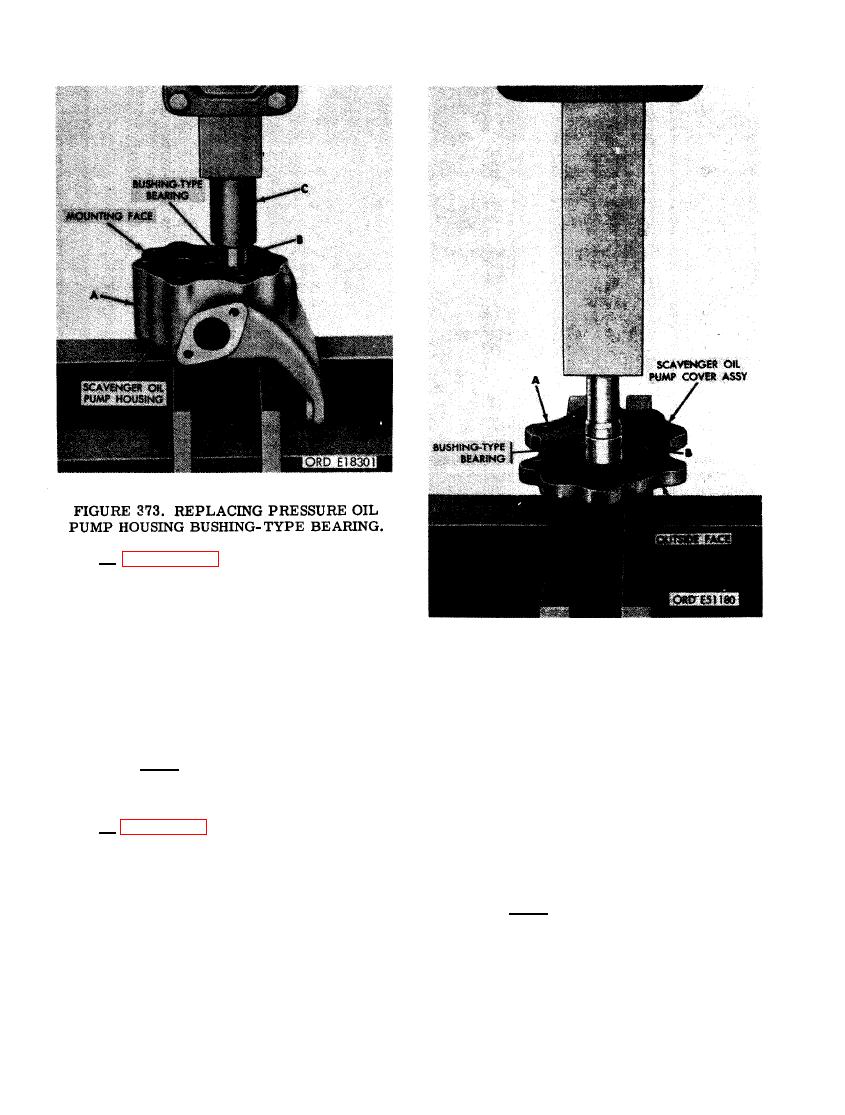

FIGURE 374. REPLACING OIL PUMP COVER BUSHING-TYPE BEARING. |

|

||

| ||||||||||

|

|

(c) Figure 374. (A) Position oil pump

cover assembly on press plates as

shown. (B) Position a new bushing-

type bearing against, and in alinement

with, old bushing-type bearing in cover

assembly. (C) Using a suitable-pres-

sing arbor, press new bushing-type

bearing into cover while pressing old

BUSHING-TYPE BEARING.

bearing out of housing. The old bearing

will act as a guide and prevent new

bushing-type bearing into impeller

bearing from becoming cocked or dis-

until the two old bushing-type bearings

torted.

are removed. Continue pressing new

bushing-type bearing until bottom end

Note. Bushing-type bearing must be

of bearing is flush to 0.010-inch below

flush with outside face of cover when

bottom end of impeller. The old bush-

properly installed.

ing-type bearing acts as a guide to

prevent new bearing from becoming

(d) Figure 375. (A) Position the pressure

cocked or distorted. Press the second

oil pump or the scavenger oil pump

bushing-type bearing into impeller

driven impeller on press plates as

until top end of bearing is flush to

shown. Allow enough clearance for the

0.010-inch below top end of impeller.

two old bushing-type bearings to clear

press plates as they are pressed out

Note. Each driven impeller contains

of impeller. (B) Position a new bush-

two bushing-type bearings. The length

ing-type bearing against, and in aline-

of the two bearings is less than the

ment with, old bushing-type bearing

t o t a l length of the impeller. The

in driven impeller. (C) Using a suit-

bushing-type bearings must be instal-

able pressing arbor, press one new

led flush to 0.010-inch below the ends

232

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |