|

|||

|

|

|||

|

Page Title:

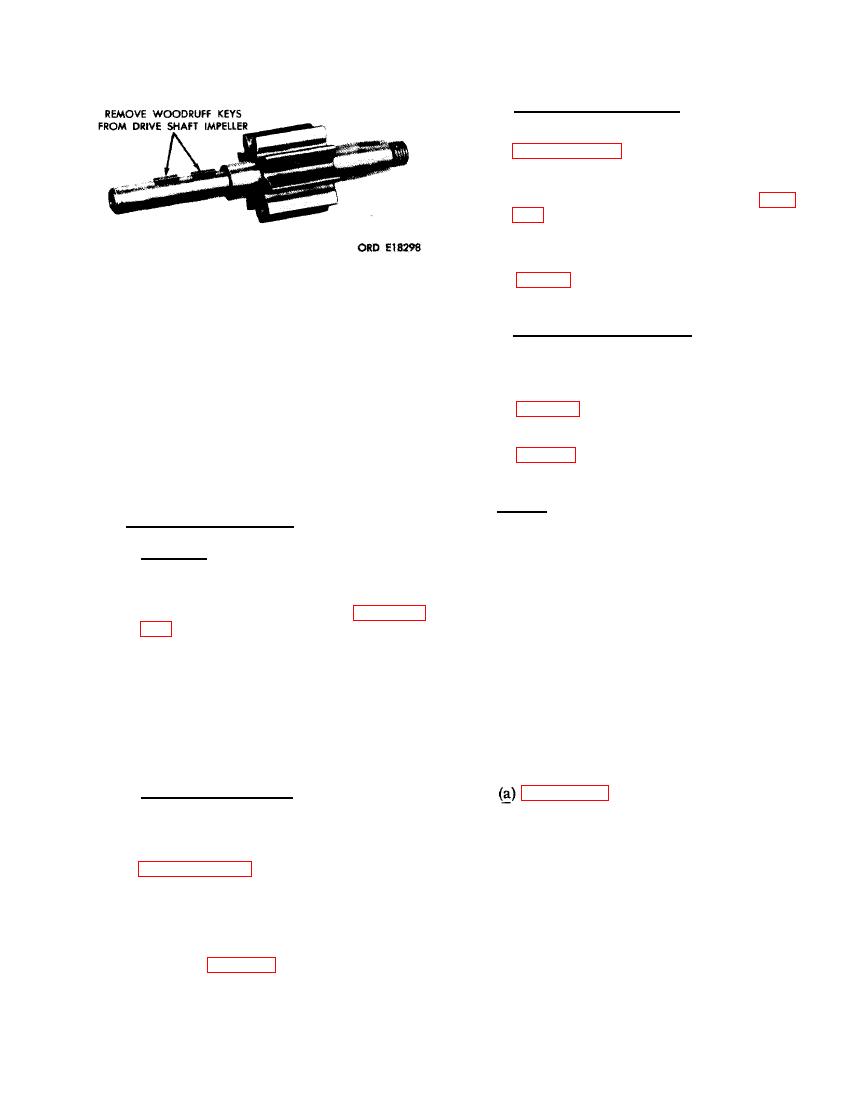

FIGURE 370. REMOVING OR INSTALLING DRIVE SHAFT IMPELLER WOODRUFF KEYS. |

|

||

| ||||||||||

|

|

(3) Inspection of Impeller. Inspect all oil

pump drive and driven impellers (AA-3,

AA-5 AA- 9 and AA- 11) as directed in

paragraph 153e. Check the drive shaft

impeller (AA-3) and driven impeller

shaft (AA- 10) against limits specified

in repair and rebuild standards (par.

293). Check bushing-type bearings (AA-

9-a and AA- n-a) for burs, out-of-

round condition and against limits speci-

fied in repair and rebuild standards

serviceable parts.

DRIVE SHAFT IMPELLER WOODRUFF

(4) Inspection of relief valve. Inspect relief

KEYS.

valve cap (AA- 15) for damaged threads

and cracks. Inspect spring (AA- 13) for

cracks and wear and against limits spec-

ified in repair and rebuild standards

cracks, burs, and against limits spec-

ified in repair and rebuild standards

c. Repair.

b. Cleaning and Inspection.

(1) The only recommended repairs to oil

(1) Cleaning. Clean pressure oil pump hous-

pump components are the replacement

ing assembly (AA- 1), scavenger oil

of bushing-type bearings in the oil pump

pump housing assembly (AA-4), and

housing assembly (AA- 1), scavenger oil

scavenger oil pump housing cover as-

pump housing assembly (AA-4), pres-

sembly (AA- 6) as directed in paragraph

sure oil pump driven impeller assembly

(AA-11), pump housing cover assembly

impeller (AA-3), scavenger oil pump

(AA- 6), and oil pump driven impeller

drive impeller (AA- 5), scavenger oil

assembly (AA- 9). Minor nicks or raised

pump driven impeller (AA- 9), pressure

metal on wearing parts can be removed

oil pump driven impeller (AA- 11), relief

using a fine mill file.

valve plunger (AA- 12), spring (AA- 13),

and cap (AA- 15) in dry-cleaning solvent

(2) Replace bushing type bearings as fol-

or mineral spirits paint thinner. Dry all

lows.

parts with compressed air.

(2) Inspection of housing. Inspect pressure

oil pump housing assembly (AA- 1),

pump housing on press plates as shown.

scavenger oil pump housing assembly

(B) Position a new bushing-type bear-

(AA-4), and scavenger oil pump housing

ing against, and in alinement with, old

cover assembly (AA- 6) as directed in

bushing-type bearing in housing. (C)

Using a suitable pressing arbor, press

check all housIng and cover mating sur-

the new bushing-type bearing into

faces for warpage. Check diameter of

pressure oil pump housing while pres-

bushing-type bearings (AA-1-a, AA-4-

sing worn bushing-type bearing out of

a, AA-6-b) in housings and cover against

housing. The old bearing will act as a

limits specified in repair and rebuild

guide and prevent new bearing from

standards (par. 293).

becoming cocked and distorted.

229

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |