|

|||

|

|

|||

|

Page Title:

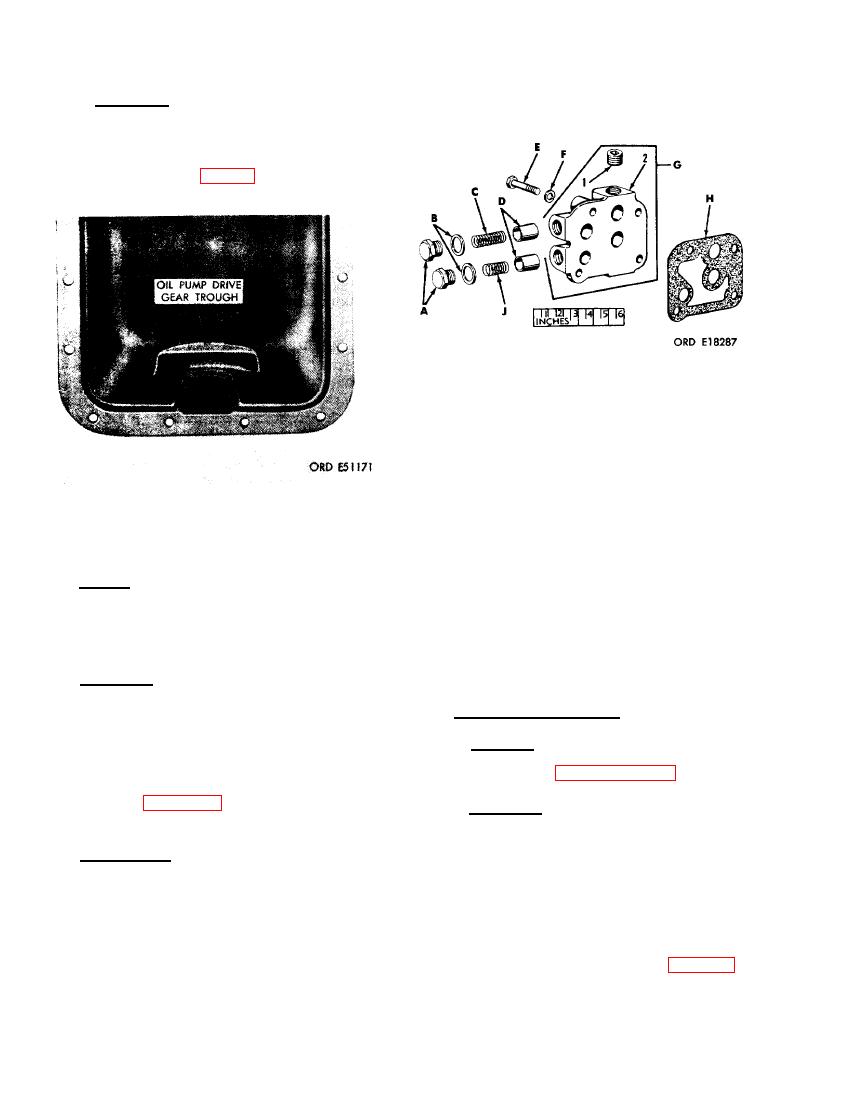

OIL PRESSURE RELIEF VALVE HOUSING |

|

||

| ||||||||||

|

|

(2) Inspection. Inspect oil drain plugs (KK)

and oil pan drain hole in oil pan for

damaged threads. Check oil pan gasket

surface for nicks and damage that might

cause an oil leak. Check oil pump drive

gear oil trough (fig. 357) in front por-

tion of oil pan for damage.

A-

3/8-in. hex head plug

B-

Plain washer (gasket)

Oil pressure relief plunger spring

C-

Oil pressure or piston oil cooling relief

D-

plunger

FIGURE 357. FRONT SECTION OF OIL PAN

E-

3/8 x 2 cap screw

SHOWING OIL PUMP IDLER GEAR

F-

3/8- in. lock washer

TROUGH.

Oil pressure relief valve housing assembly

G-

1- 3/8-in. pipe plug

c. Repair. Remove all nicks, raised metal,

2- Oil pressure relief valve housing

and warpage on oil pan gasket surface using a

Housing gasket

H-

fine mill file. Repair damaged drain plug threads

J-

Piston oil cooling relief plunger spring

in pan and on drain plugs (KK). Replace oil pan

when damaged beyond minor repairs.

HOUSING AND RELATED PARTS -

d. Assembly. Loosely install drain plugs

EXPLODED VIEW.

(KK) in threaded holes in oil pan using new

gaskets (JJ).

-- . Cleaning and Inspection.

b

192. OIL PRESSURE RELIEF VALVE HOUS-

(1) Cleaning. Clean oil pressure relief

ING

valve housing (G-2) and components as

directed in paragraph 152c and d.

Note. The key letters shown below in paren-

theses refer to figure 358 except where other-

(2) Inspection. Inspect oil pressure relief

wise indicated.

valve housing (G- 2) for cracks, stripped

threads, nicks, scratches, and burs on

a. Disassembly. Remove plug (A), plain

mounting faces. Check oil passages for

washer (gasket) (B), oil pressure relief plunger

cleanliness and freedom from obstruc-

spring (C), and oil pressure relief plunger (D)

tions. Inspect plunger bores for scoring

from oil pressure relief valve housing assembly

or evidence of wear. Inspect plugs (A)

(G). Remove plug, plain washer (gasket), piston

for damaged threads and cracks. Inspect

oil cooling relief plunger spring (J), and piston

the springs (C and J) for cracks and

cooling relief plunger (D) from oil pressure

wear and against limits specified in

relief valve housing assembly. Remove two

repair and rebuild standards (par. 293).

3/8-inch pipe plugs (G-1) from housing (G-2).

Inspect plungers (D) for cracks, burs,

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |