|

|||

|

|

|||

|

Page Title:

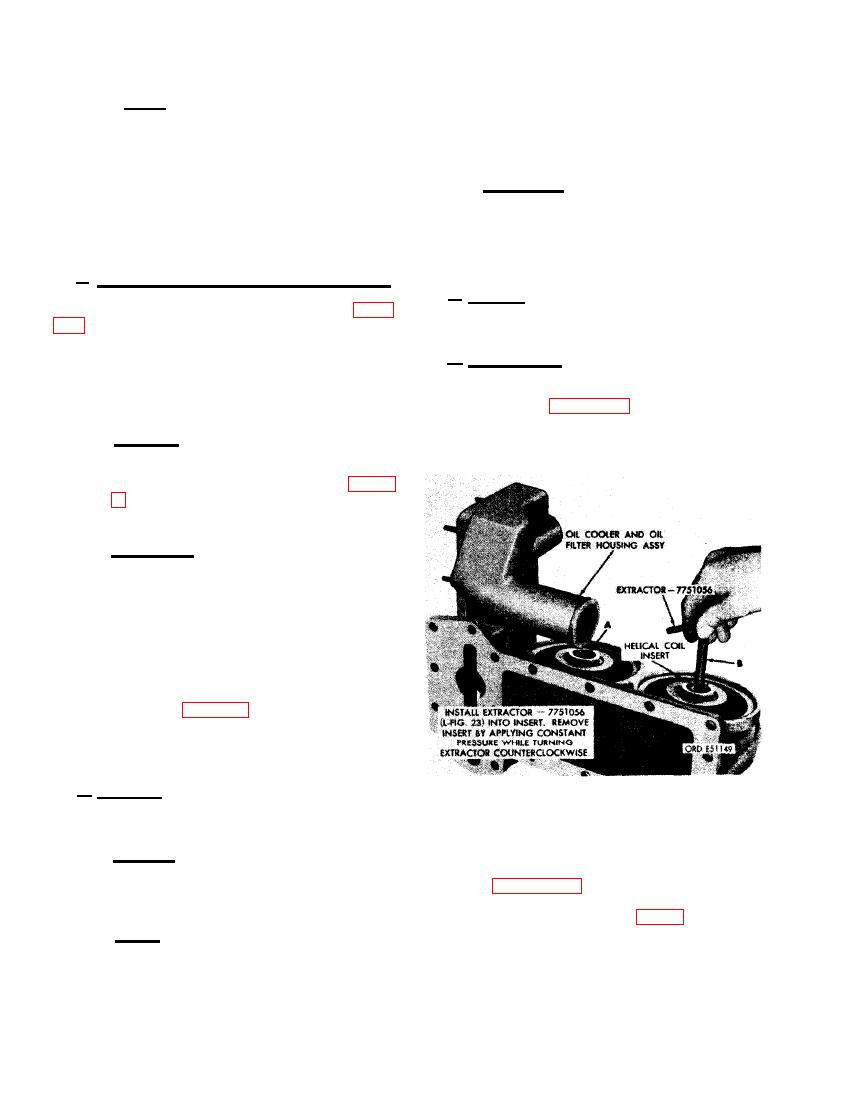

REPLACEMENT OF HELICAL COIL THREADED INSERTS |

|

||

| ||||||||||

|

|

move slight nicks, burs,

and scratches

Note. There are no established wear

limits for gear teeth. Good judgement

from bore in casting or

adapter with

is required to determine need for re-

crocus cloth dipped in

dry-cleaning

solvent or mineral spirits

paint thinner.

placement.

(3) Replace gears having worn, pitted, or

(3) Installation. Install new oil seal in bore

galled teeth. Remove sharp fins and

of casting or adapter using proper oil

seal replacer tool.

burs from gear teeth with crocus cloth

d i p p e d in dry-cleaning solvent or

mineral spirits paint thinner.

THREADED INSERTS

f. Bushings and Bushing-type Bearings.

When bushings and bushing-type bearings are

a. General. Replace helical coil inserts which

damaged or worn beyond specified limits (pars.

do not fit securely in the casting or when

casting threads have become galled or stripped.

with which they are used must also be replaced.

Reference to (1) and (2) below will be made in

helical

b. Replacement.

Replace

coil

the rebuild section for the particular part when

threaded inserts as follows.

replacement of bushings and bushing-type bear-

ings is required.

(1) Refer to figure 315 and remove helical

coil insert from oil cooler and filter

(1) Removal. Remove bushings or bushing-

housing.

type bearings by pressing out the part

with a suitable arbor press or with the

special tools provided. Refer to Table

ment.

(2) Installation. Aline bushing or bushing-

type bearing in casting or retaining

cage. Press into place with a suitable

arbor press or with the special tools

provided. Clean repaired parts thor-

oughly before assembly or installation.

(3) The bushing-type bearings in the oil

pump must be finished reamed to the

sizes specified in repair and rebuild

standards (par. 293c) after installation.

All other bushing-type bearings are

machined for proper clearance and

need no reaming.

g. Oil Seals. Oil seals must be replaced when

thin feather edge is damaged or when seal

material has become hard or brittle.

INSERT FROM OIL COOLER AND OIL

FILTER HOUSING USING EXTRACTOR -

(1) Removal. Press or pry damaged oil

7751056.

seal from casting or adapter being

careful not to damage bore in casting

(2) Figure 316. (A) Thread new helical

or adapter.

coil insert into threaded guide of in-

serter - 10912379 (M, fig. 23) by slowly

(2) Repair. When oil seal bore in casting

turning the pilot until insert is flush

or adapter is burred or damaged to a

with end of tool. (B) Insert pilot of

point where an oil-tight seal is impos-

inserter into threaded hole in oil cooler

sible, replace casting or adapter. Re-

and oil filter housing with face of in-

192

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |