|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

d e f e c t s and subjected to the tests outlined in the

3. Average entrance temperature = 88 F

technical manual.

4 . Fuel temperature = 70 F

(2) F i f t y - h o u r q u a l i t y c o n t r o l t e s t s c h e d u l e .

5. Torque arm = 1.75 feet

Each engine selected in accordance with sub

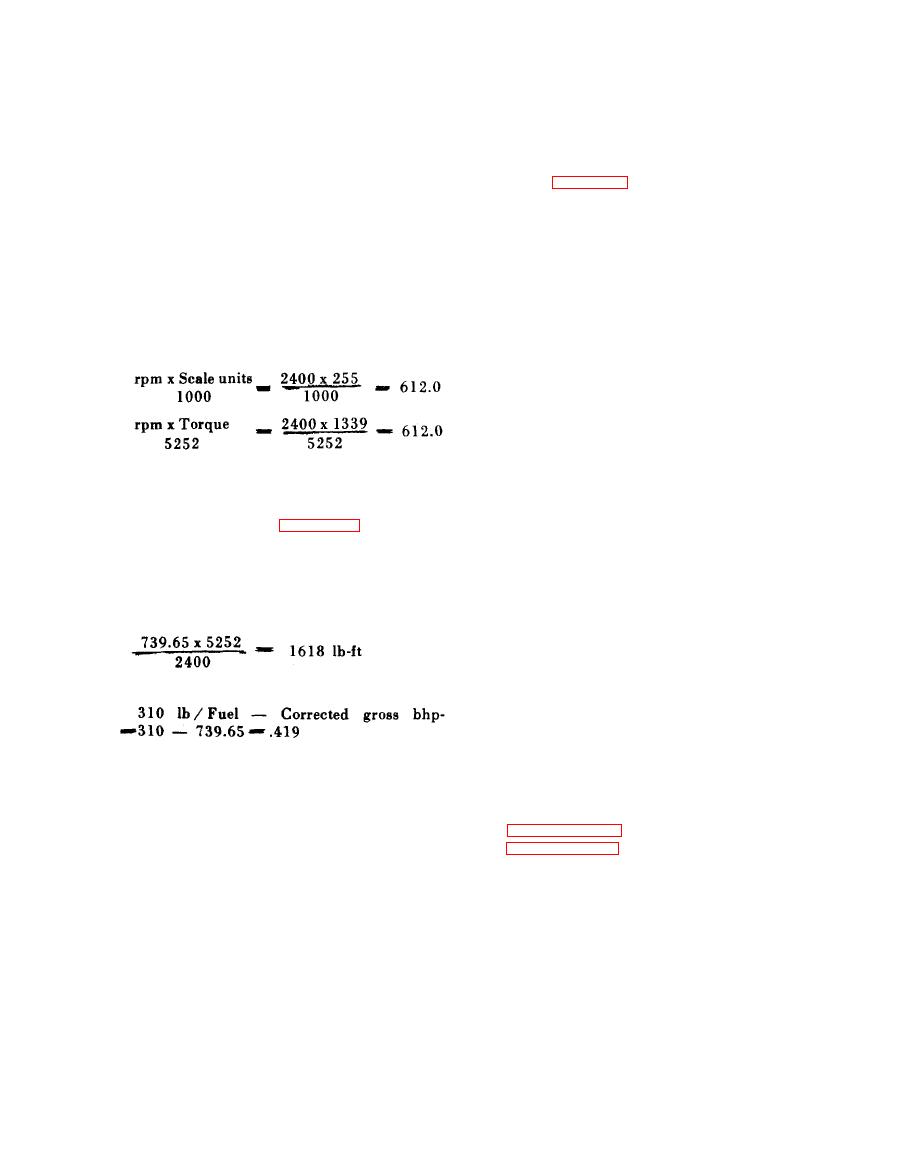

Correction Factors:

paragraph (1), above, shall be operated, as

1. Dry entrance pressure (1) in inches Hg -

specified in table 8-6, for 50 hours as nearly

Absolute 29.35-0 (2) = 29.35 = Correc-

continuously as possible

tion = .0067

(a) Starting with run No. 3, an oil con-

2. Average entrance temperature 88 F (3) -

sumption reading shall be taken each one-half

Correction = .0154

( ) hour when operating at 2400 rpm full load.

3. Fuel temperature (4) - Correction = .010

(b) A blow-by check shall be made at

4. Total correction - .0067 + .0154 +

2 4 0 0 rpm full load prior to runs No.'s. 3-11-15-

.010 = 1.0321

19 and 22. Normal reading will be 11 to 15

SAMPLE

CALCULATIONS:

cubic feet per minute (CFM). Maximum per-

m i s s i b l e blow-by is 18 cfm. The blow-by can be

bhp Observed

m e a s u r e d with a volumeter or gas meter between

(c) Approximately 100 amp's load shall

b e applied to the generator during the complete

test.

(d) Readings shall be taken every one-half

Correction Net bhp

( ) hour and will include all data taken on the

regular test.

612.0 X 1.0321 = 631.65

Fan hp

(3) Corrections. Engine subjected to this

Fan hp@2400 rpm (Table 8-5) = 108

test shall be completely disassembled and all

i n t e r c h a n g e a b l e parts subjected to wear or stress

Corrected Gross b h p

Corrected net bhp + Fan hp = 631.65 +

shall be inspected. A complete report including

108 = 739.65

t h e inspection and testing of the engine shall be

Corrected Gross Torque

submitted to the Government inspector. Should

Corrected gross bhp x 5252 =

there be evidence of failure of parts requiring

c o r r e c t i o n as a result of this test, the inspector

s h a l l refuse acceptance of subsequent production

engines until such corrections have been made

a n d objective e v i d e n c e p r e s e n t e d t o t h e

Brake Specific Fuel Consumption

G o v e r n m e n t inspector. Engines subjected to this

test shall be reassembled with new parts

replacing those found unsatisfactory during

8-7. Quality Control lest

examination.

(4) Disposition of engines. After correction

a. General. A 50-hour quality control test shall

of all defects disclosed by the test, engine shall be

b e conducted for the purpose of determining the

reassembled, given a final run in accordance

continued quality of the engine.

with paragraph 8-4, inspected in accordance

b. Control Test.

with paragraph 8-6, and if found acceptable,

( 1 ) Selection of test s a m p l e . E n g i n e s s h a l l

shipped as a regular production engine.

be selected at the rate of one per month when

(5) Control test failure. Failure of a control

production is below 100 per month; or one in

t e s t engine to pass any specified examination or

e v e r y 100 engines when production exceeds 100

test shall be cause for rejection of subsequent lots

units per month; or on curtailed production at

until satisfactory evidence is submitted to the

least one every 60 days. Test engines shall be

g o v e r n m e n t inspector that the faults revealed by

i d e n t i f i e d as to production period, examined for

the examination or test have been corrected.

8-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |