|

|||

|

|

|||

|

Page Title:

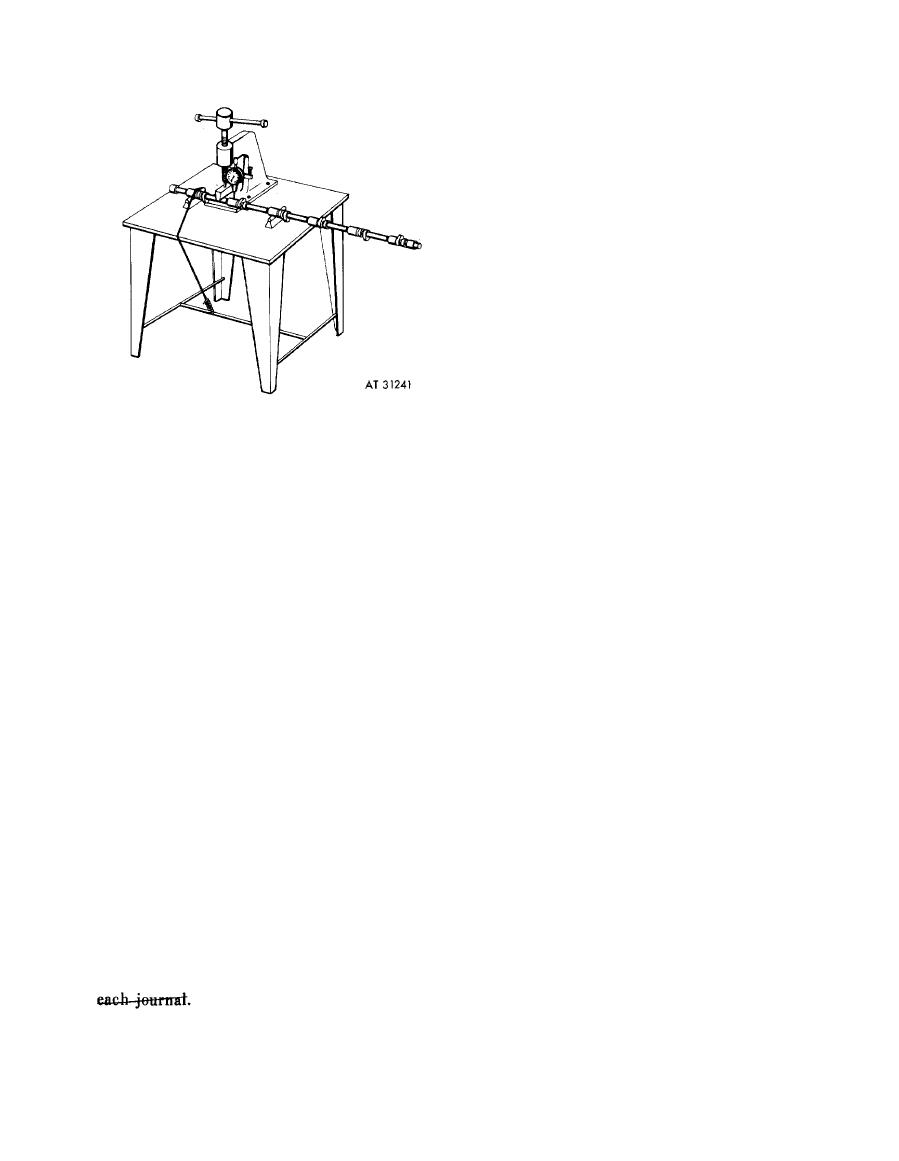

Figure 6-214. Improvised camshaft trueing device. |

|

||

| ||||||||||

|

|

(5) Check

runout

of

each

camshaft

bearing

journal.

Support

the

camshaft

in

"V"

blocks at the adjacent journals, and using a dial

indicator,

check

and

record

journal

runout

(TIR) dimensions. If runout exceeds 0.002 inch,

cam

shaft

must

be

straightened.

(b) S t r a i g h t e n i n g c a m s h a f t .

(1) Install camshaft on trueing device

with

bearing journal having the maximum

runout

(TIR)

positioned

under

the

pressing

spindle. (The camshaft journals must be resting

on the support blocks when rotating the cam-

shaft to determine the runout.) Set dial on in-

dicator

to

"zero"

and rotate camshaft to

determine location of runout (TIR) and record

reading.

(2) Turn camshaft until bearing

journal

marked to indicate the maximum runout

(high side) is adjacent to the spindle (do not

press on journals). Apply spindle pressure on the

trueing device.

camshaft

until

dial

indicator

reads

ap-

(a) C h e c k i n g c a m s h a f t b e a r i n g j o u r n a l

proximately one

half

of

the

TIR

reading

run-out. Camshafts may be straightened if the

recorded

in

(a),

above.

Release

pressure

on

runout

of

any

one

camshaft

bearing

surface

cam shaft and recheck runout by turning

(journal), when using a dial indicator, does not

camshaft several revolutions.

exceed 0.060 inch total indicator reading (TIR)

Note. Pressing force required to straighten

when

supported

at

the

two

adjacent

bearing

cam shaft is a matter of judgement. It may be

journals. Camshafts that exceed 0.060 inch

necessary to turn camshaft and apply pressing

runout between any two journals must be

force several times in order to acquire the

discarded.

Maximum

journal

runout

of

technique necessary to true the bearing journal.

straightened camshafts is 0.002 inch (TIR)

(3) Apply pressure as required until the

when supported at the two adjacent journals.

journal is within the 0.002 maximum TIR.

After

straightening

a

camshaft,

the

maximum

(4) R e p o s i t i o n c a m s h a f t o n s u p p o r t s

acceptable runout of the center bearing journal,

and

true other bearing journals is a similar

when supported at the end journals, is 0.015

manner.

inch (TIR). Check

camshaft

bearing

journal

(5) After trueing all bearing journals,

runout as follows:

recheck camshaft as outlined in procedure (a),

(1) Support the camshaft at the two

above.

If

readings

do

not

meet

dimensions

end journals in "V" blocks on a surface plate or

specified,

repeat

trueing

operation.

other available centering device, such as a

(c) Inspection

of

camshaft

after

machine

lathe.

straightening.

(2) Position

a

dial

indicator

at

the

(1) M a g n a f l u x

each

camshaft

and

center bearing journal and obtain a zero reading

inspect for cracks. Observe transition areas at

on the dial.

bearing surfaces and at cam lobe bases. Cam-

(3) Rotate the camshaft and determine

shafts with evidence of cracks must be discarded.

the maximum travel of the dial indicator needle.

(2) Inspect for damage to bearing

If travel (TIR) exceeds 0.015 inch the camshaft

journals. M i n o r n i c k s a n d s c r a t c h e s c a n b e

must

be

straightened.

removed using crocus cloth.

(4) Repeat steps (2) a n d (3), a b o v e f o r

(3) Check bearing journals for out-of-

each

bearing journal and mark position and

round to be certain area was not flattened during

dimension of maximum dial indicator reading at

trueing.

Maximum

acceptable

out-of-round

is

0.002

inch

(TIR).

Replace

camshaft

if

this

tolerance

is

exceeded.

6-179

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |