|

|||

|

|

|||

|

Page Title:

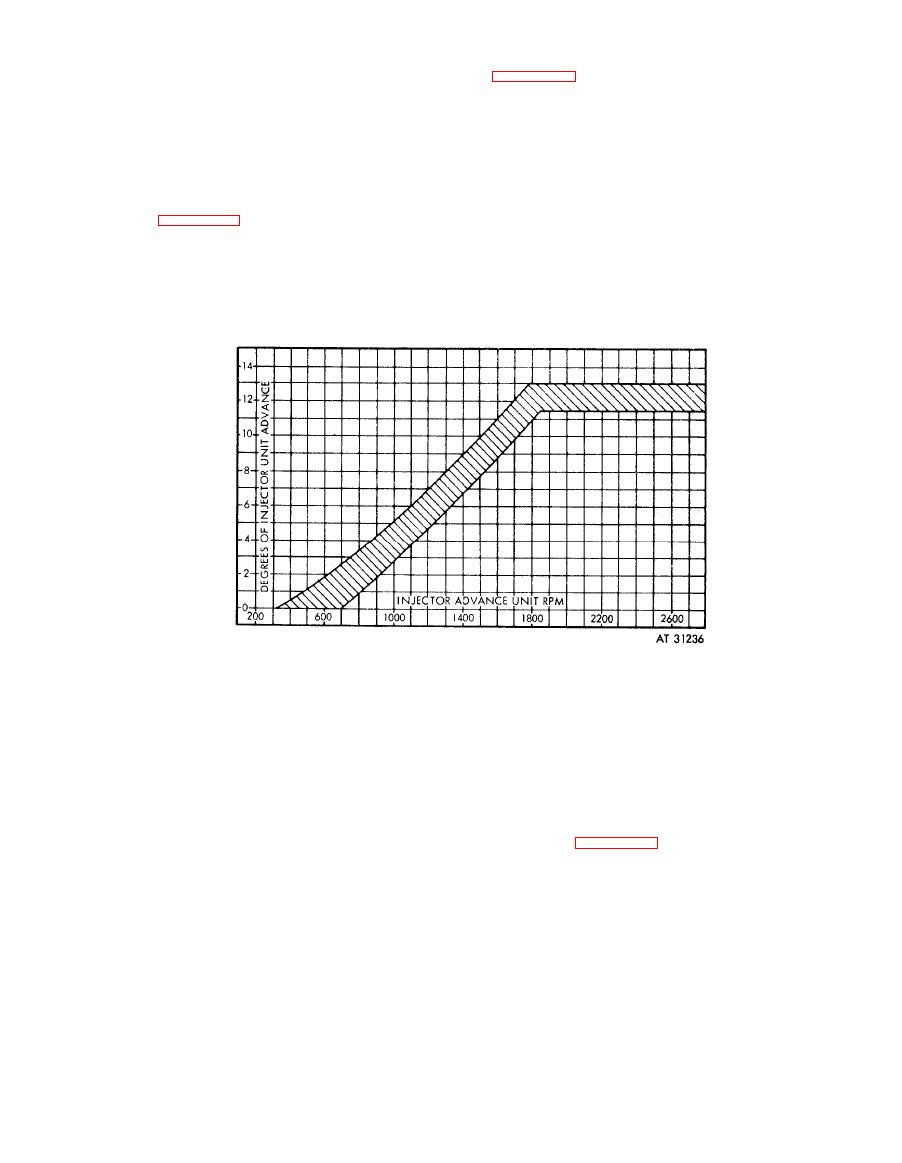

Figure 6-200. Fuel injector advance unit curve |

|

||

| ||||||||||

|

|

(0), figure 6-199b, to reduce speed and counter

counter reading at each 200 rprn increment

switch, motor switch, and master switch handle

increase, beginning at 600 rpm and continue

to the "OFF" position.

through

to

2600

rpm.

Note. Injector pump advance assembly

(m) Reduce speed to 600 rpm and re-

will be hot following test. Operator should wear

check counter reading. If this reading does not

gloves when removing unit from test stand.

check with the original repeat the test. Check the

readings taken at each 200 rpm increase against

(o) Loosen fasteners and remove cover.

Remove

bearing

caps

and

remove

unit

from

similar points on the approved advance unit

bench. Remove oil transfer shaft. Place injector

curve, figure 6-200. If the recorded advance

advance pump assembly on oil drain tray with

readings fall within the prescribed limits on the

small gear end up. Place advance assembly in a

curve,

the

test

is

complete.

If

the

advance

readings do not meet the curve limits, proceed

clean

dirt-free

container,

preferably

a

with step (p) below.

polyethylene bag, for storage after draining and

cooling.

(n) Turn speed regulator control to zero

Figure

6-200.

Fuel

injector

advance

unit

curve.

(p) Repeats steps (h) through (m) to

(r) Push speed control stop switch to

check

previous readings. If advance assembly

disengage eddy current clutch. Turn counter,

fails to pass the test, it must be adjusted. Note

motor, and motor starter off.

whether advance assembly advances too soon or

(s) Loosen fasteners and remove cover.

too

late.

Either

condition

can

normally

be

Remove two cotter pins, and loosen the two

corrected

by

rotating

the

advance

flyweight

slotted nuts enough to permit adjusting ring

adjusting ring.

rotation. See figure 6-201.

Note. The advance assembly should be

Note. Do not turn the adjusting ring more

retarded slightly if the advance varies more than

than 1 /

16

of

an

inch

during

any

one

ad-

2 degrees at 300 rpm when the oil pressure drain

justment.

button is depressed. This variance indicates the

mechanical retard stop is not in phase with the

hydraulic valve.

6-168

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |