|

|||

|

|

|||

|

Page Title:

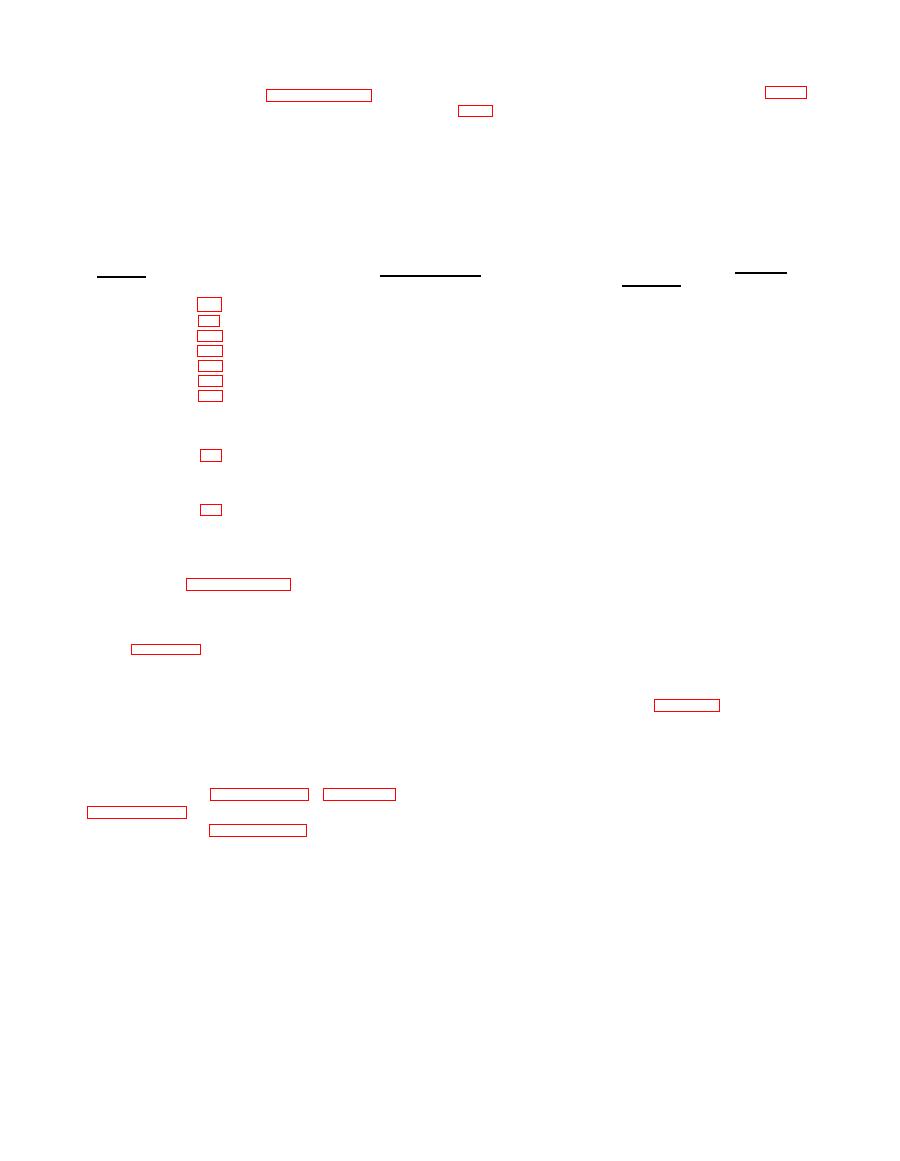

Table 6-22. Crankshaft Damper and Oil Filter Housing Control Valves - Overhaul Standards |

|

||

| ||||||||||

|

|

the limits specified in overhaul standards (table

(1) through (3), below.

( 3 ) Inspect the main oil filter elements for

( 1 ) I n s p e c t t h e o i l t e m p e r a t u r e gage

plugged, coated, cracked, or damaged screens.

transmitter and high oil pressure warning light

Inspect main oil filter cover handle and spring

s w i t c h for damaged threads or deformity. Check

for damage. Inspect auxiliary oil filter cover

electrical circuit for continuity.

handle and support for damage.

(2) Inspect oil presure regulator plunger,

spring, and sleeve and bypass valve springs to

Table 6-22. Crankshaft Damper and Oil Filter Housing Control Valves - Overhaul Standards

Sizes and fits

Wear limits

Ref.

Fig.

Point of measurement

Component

of new parts

letter

No.

--

Inside diameter of sleeve (small)

0.8125

0.8135

B

pressure B-6

0.8145

Oil

Outside diameter of plunger (small)

0.8095

0.8105

E

0.8085

regulator plunger B-6

Fit of plunger in sleeve (small)

0.0020L

0.0040L

B-E

0.0060L

Inside diameter of sleeve (large)

1.1885

1.1865

F

1.1905

Outside diameter of plunger (large)

1.1840

1.1850

C

1.1830

Fit of plunger in sleeve (large)

0.0015L

0.0045L

F-C

0.0075L

Valve spring:

D

*

Approximate free length of spring

2.83 inch

*

Scale reading at 1.825 inch length

2 9 . 3 lb 3 lb

*

Maximum solid height

1.284 inch

Bypass valve spring:

A

Oil filter and oil B-6

Approximate free length of spring

*

cooler pressure

4.28 inch

Scale reading at 2.81 inch length

*

relief

bypass

52.3 lb 5 lb

Maximum solid height

*

valve springs

2.261 inch

Approximate free length of spring

*

oil

Auxiliary

2.40 inch

G

Scale reading at 1.75 inch length

*

filter

bypass

9 . 1 2 lb 1.0 lb

Maximum solid height

*

p r e s s u r e relief

0.988 inch

*

v a l v e spring

d. Repair.

(a) Repair of housing is permissible to

include replacement of metal cracks, or chips.

( 1 ) To replace main oil filter cover handle

Repair shall be accomplished to prevent oil

(63, fig. B-6), remove spring (66), spread

l e a k a g e between compartments, cast in passages,

handle, and remove handle from cover. Spread

a n d drilled passages. Repair shall not impair the

n e w handle and install on cover with spring. To

normal oil flow pattern (fig. 6-112) or be re-

replace auxiliary oil filter cover handle (20) or

s t r i c t i v e to the oil flow and shall not impair the

support, spread handle and remove from cover.

normal functions of control valves and filtering

Remove rivet (22) and remove support from

functions.

c o v e r . Position new support in cover and install

rivet. Spread new handle and install on cover.

(b) After welding repair of the housing,

visually inspect passages and compartments for

( 2 ) Refer to paragraph 6-4e, table 6-23, and

obstructions and foreign material. Flow test

( 3 ) Refer to paragraph 6-4c for general re-

passages to assure proper functioning and oil

pair and welding instructions and (2) and (b),

control. Leak test compartments and drilled

b e l o w , for specific information on welding repair

passages and pressure check to 20 psi.

o f the crankshaft damper and oil filter housing.

6-106

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |