|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-270-34

REPAIR FRICTION CLUTCH

DESCRIPTION

This task covers. Disassemble (page 4-211). Assemble (page 4-214).

INITIAL SETUP

Materials/Parts:

Tools:

Transmission oil -- (Item 12, App B)

"C" clamp (2) (Item 18, App C)

P r e f o r m e d packing

General mechanic's tool kit:

Friction clutch repair kit

automotive -- (Item 33, App C)

Industrial goggles (Item 39, App C)

Personnel Required:

Inside/outside indicator caliper --

(Item 41, App C)

Track Veh Rep 63H10

Micrometer caliper set -- (Item 52, App C)

Retaining-ring pliers (Item 59, App C)

Equipment Conditions:

Socket wrench attachment --

Friction clutch on workbench. See

(Item 79, App C)

Socket wrench set (Item 89, App C)

Telescoping gage set (Item 93, App C)

Torque wrench -- (Item 99, App C)

Compressed air source, 30 psi

(207 kPa) maximum

DISASSEMBLE

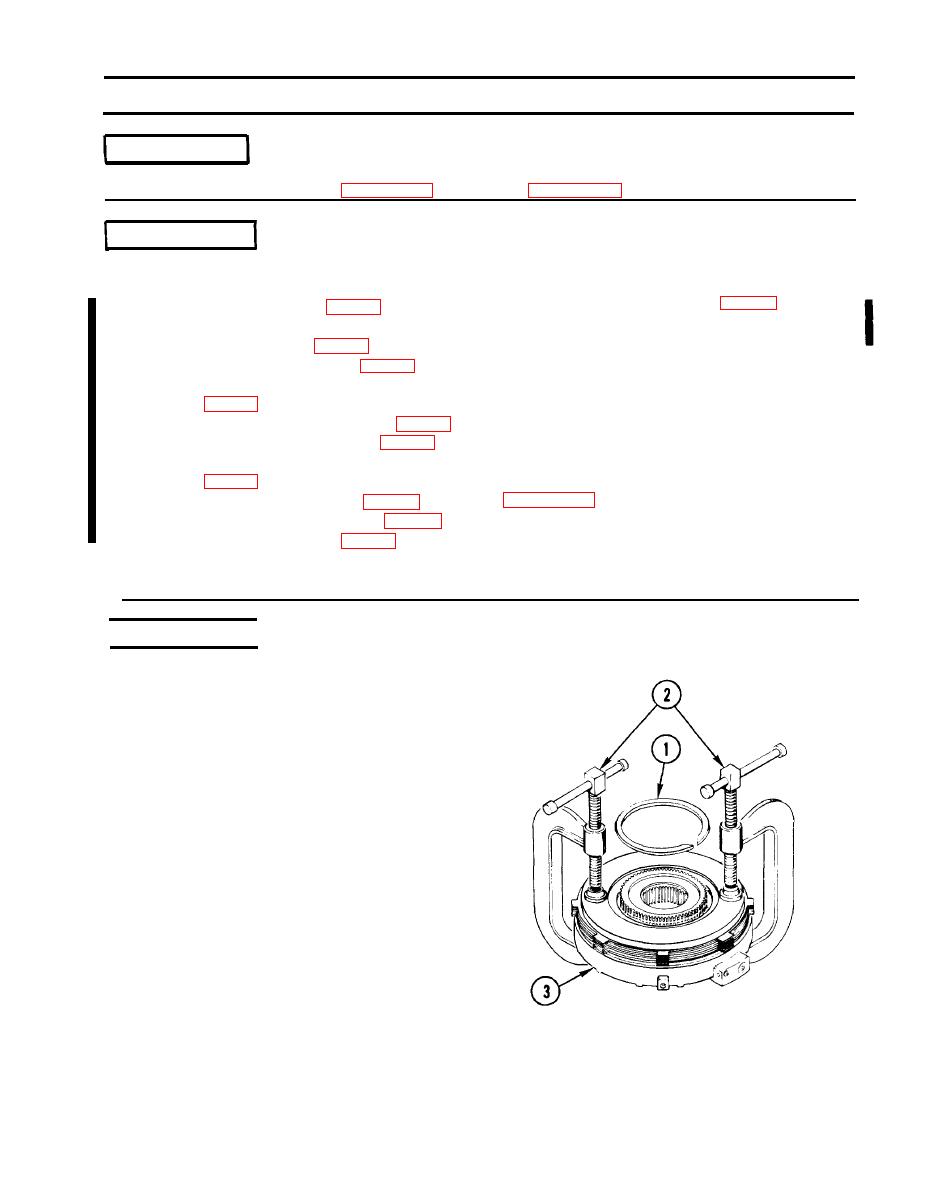

1. REMOVE RETAINING RING (1).

a. Place two "C" clamps (2) on friction

clutch (3) opposite each other.

b. Tighten two "C" clamps (2) evenly

until pressure is relieved on

retaining ring (1).

c. Using retaining-ring pliers, remove

retaining ring (1).

GO TO NEXT PAGE

4-211

Change 1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |