|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-249-34&P

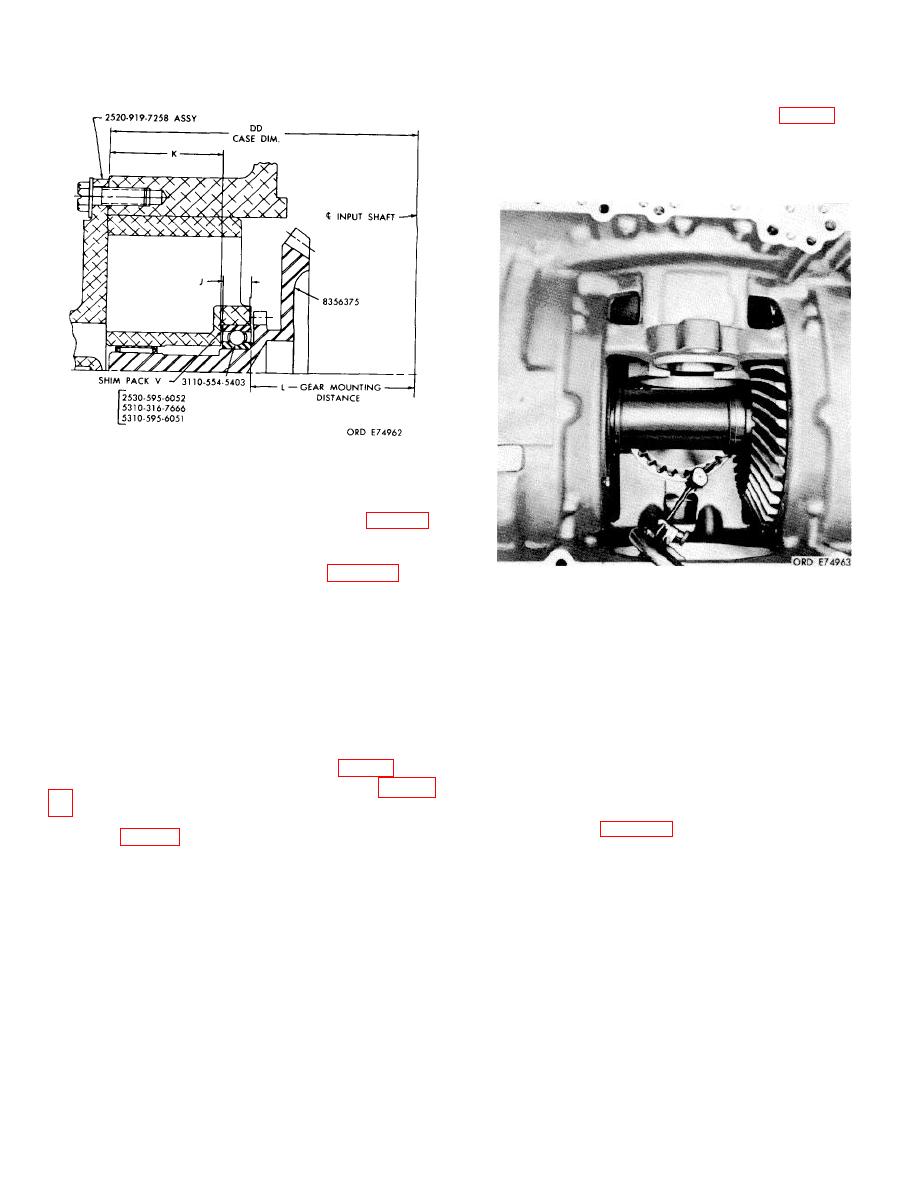

etched on the gear. Backlash may be adjusted by

adding or removing shims from shim pack V fig. 8-8).

NOTE

The cross shaft must be held stationary to

obtain correct backlash reading.

Figure 8-8. Nominal shims for brake coolant pump gear

From the bottom of the bearing bore in the pump cody,

to upper surface of the pump cover (pump assembled).

substituting dimensions for DD, J, K and L in the formula

Figure 8-9. Checking coolant pump drive gear tooth

V = DD - K - J - L.

contact pattern and backlash

NOTE

DD is stamped on a web of the bevel gear

g. When gear pattern, backlash, and bearing

housing; J was obtained in a, above; K was

preload are properly established for all the gears,

obtained in b, above; L is the gear mounting

recheck all bolts for tightness.

distance (MD) etched on the pump drive gear.

8-10. Preliminary Assembly

d. Select the combination of shims 2530-595-

All thrust surfaces, gears, sealrings, splines, bushings

6052, 5310-316-7666 and 5310-595-6051 which most

and bearings must be oiled as they are installed.

nearly equal V. Install the shims and gear (fig. 8-8).

8-11. Assembly Pictorial Steps

The assembly of the transmission from subassemblies

f.

Check the gear tooth contact pattern and

(as discussed in chapter 7) is outlined in the following

backlash (fig. 8-9). The backlash (BL) should be that

consecutive pictorial steps (1 through 125).

8-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |