|

|||

|

|

|||

|

Page Title:

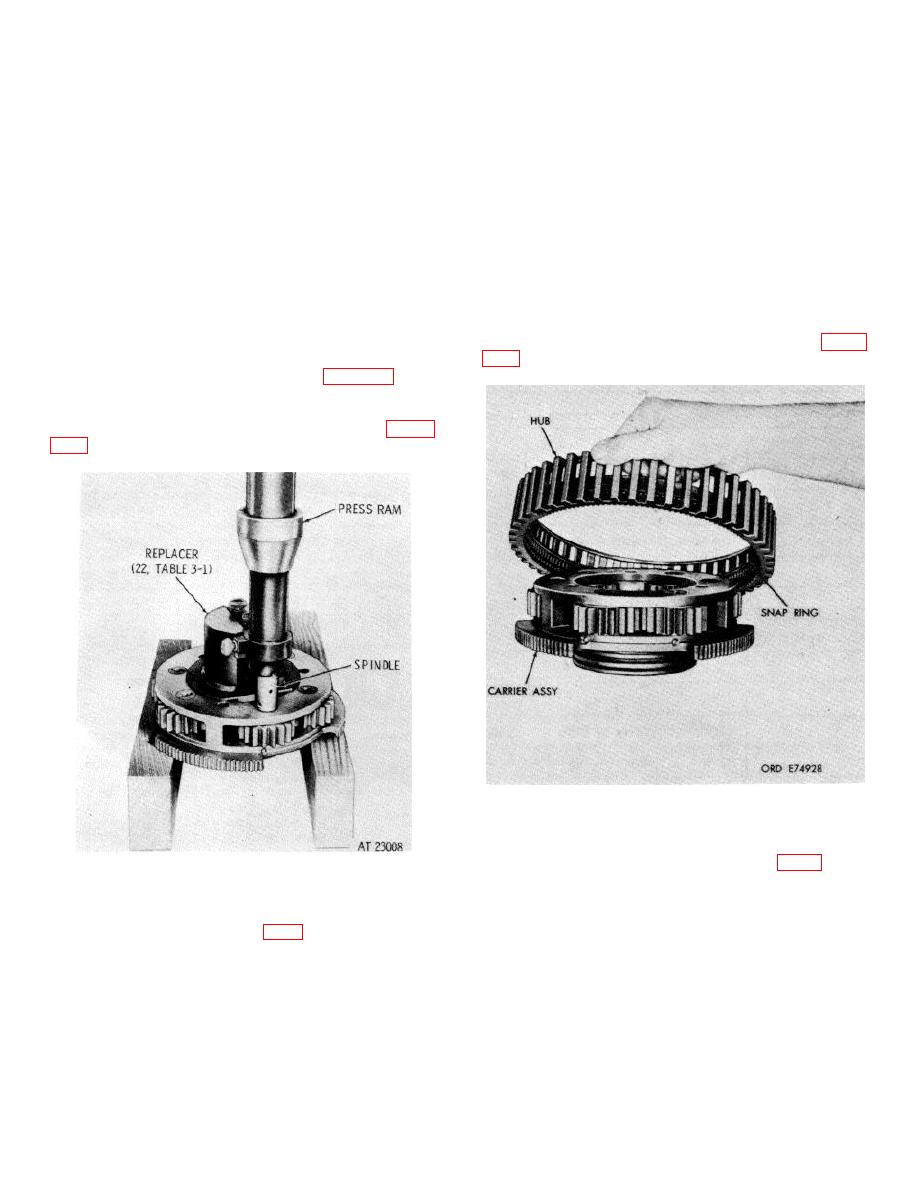

Figure 7-28. Installing spindle into reverse-range planetary carrier. |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

Stake carrier metal over the pin at two places.

a. If the six pins (37) were removed, install

i.

Install the remaining five pinions, each with

new ones. Press the pins into the carrier, to 0.010 inch

its associated parts, and pins (39.8) into the carrier as

below the plug bore surface of carrier (38). Stake metal

described in b through h, above.

over each plug at two places.

j.

Install retaining ring (40) into the hub of

b. Grease the bore of a pinion (39.4) with a

planetary carrier assembly (36).

liberal amount of oil-soluble grease.

k. Install bearing (34) into the hub of carrier

c. Install a spacer (39.3) and a thrust washer

assembly (36). Press the bearing until it is firmly seated

(39.2) on one side of pinion (39.4).

against retaining ring (40).

d. Install 25 pinion rollers (39.5) inside pinion

l.

Install retaining ring (33) into the hub of

(39.4) around the bore wall.

carrier assembly (36).

e. Install another spacer (39.6) and another

m. Install retaining ring (44) into reverse-range

thrust washer (39.7) on the other end of pinion (39.4).

clutch hub (43).

f.

Install the pinion with rollers, washers and

n. Install hub (43) with retaining snap ring (44)

spacers into the carrier, using alining tool of replacer

onto reverse-range carrier assembly (36), Refer to figure

(22, table 3 1) to aline the pinion components with the

spindle bore in the carrier.

indexing the spindle and replacer, install the spindle into

the carrier. Press the spindle flush with, to 0.010 inch

below, the spindle bore of the carrier. Refer to figure

Figure 7-29. Installing reverse-range clutch hub onto

carrier assembly.

Figure 7-28. Installing spindle into reverse-range

reverse-range clutch hub (43).

planetary carrier.

p. Install two sealrings (41 and 42) onto the

hub of reverse-range carrier assembly (36). Retain

them with soluble grease.

to 0.090 inch below the pin bore surface of carrier (38).

7-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |