|

|||

|

|

|||

|

Page Title:

Section XII. BEVEL GEAR HOUSING ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

Table 7-9. Repair Standards (Right, Left Cross-Shaft Bearing Retainers) - Continued

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

5

21a

Inside diameter at bearing surface of ...

4.9930 to 4.9940

4.9945

retainer

5

46a

Outside diameter of bearing outer race .

5.000 to 5.0010

*

5

21a

Fit of bearing outer race in retainer .......

0.0060T to 0.0080T

46a

5

21b

Outside diameter of bearing retainer at

6.246 to 6.250

6.242

sealrings

5

22a

Inside diameter of sleeve bearing at......

5.000 to 5.002

5.0040

sealring

*Replace when worn beyond new dimensions.

Section XII. BEVEL GEAR HOUSING ASSEMBLY-REPAIR

necessary, or to aid in cleaning the housing.

7-68. Description

d. Do not remove dowel pins (13, 14, 15, and

Refer to paragraph 2-25 for a description of the bevel

17) unless replacement is necessary.

gear housing components.

7-70. Cleaning

Refer to paragraph 5-2 for cleaning recommendations.

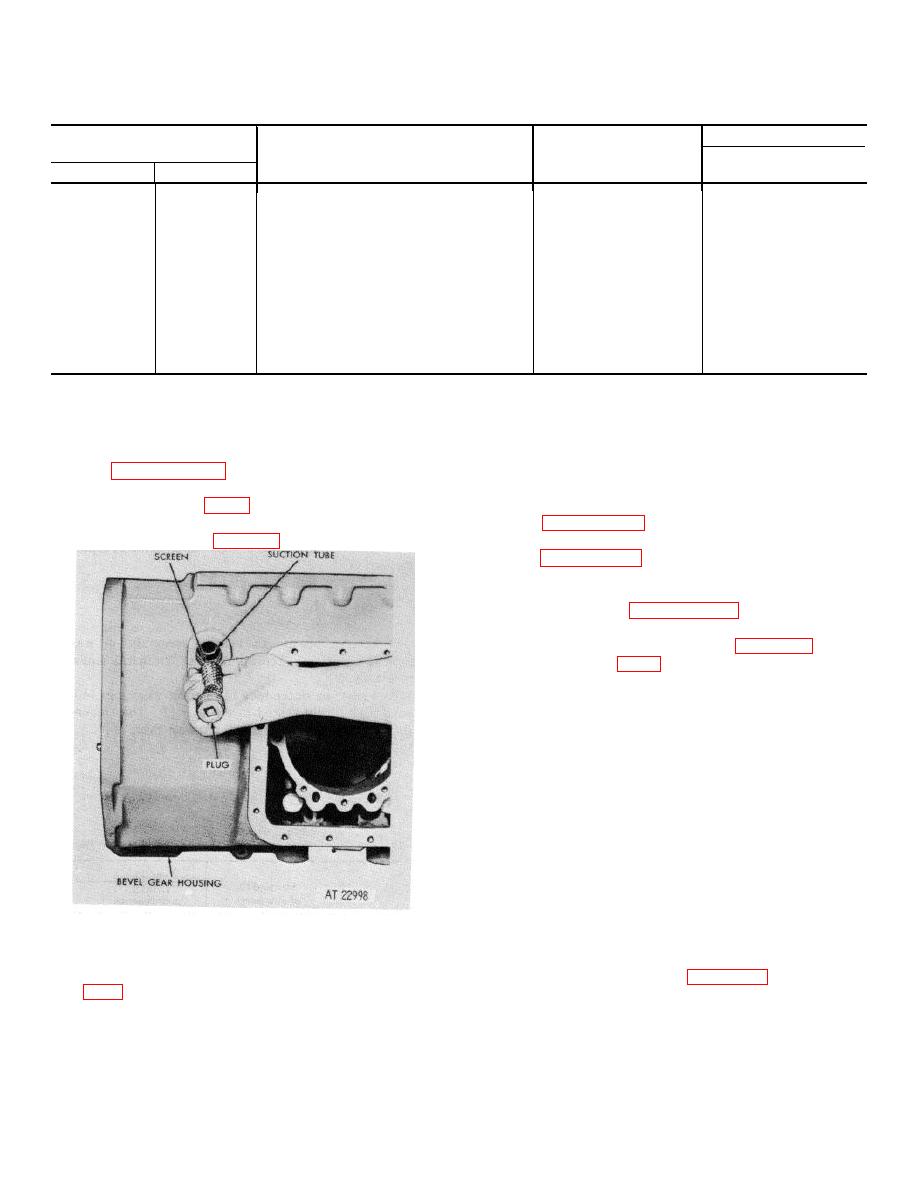

a. Remove plug and output pump screen from

7-71. Inspection and Repair

the bevel gear housing (fig. 7-15).

Refer to paragraph 5-3 for general inspection and repair

recommendations.

7-72. Repair Standards

repair standards.

a. If dowel pins (13) were removed, press

replacements into housing (9), so that they extend 0.30

inch above the housing surface.

b. If dowel pins (14, 15 and 17) were

removed, press replacements into housing (9), flush

with, to 0.03 inch below, the housing surface and stake

metal over the pins.

c. If dowel pins (18) were removed, press

replacements into housing (9), so that they extend 0.20

inch above the housing surface.

d. If plugs (11 and 12) were removed, install

the plugs.

e. If output pump suction tube (16) was

removed from housing (9), install a new replacement.

Press the tube until the shoulder of the tube is firmly

Figure 7-15. Removing (or installing) plug and output

seated in the housing.

pump screen.

f.

Install output pump screen (26) and plug

b. Do not remove output pump suction tube

(27) into housing (9). Refer to figure 7-15.

(16. FO-5) unless replacement is necessary.

c. Do not remove plugs (10, 11 and 12) from

bevel gear housing 19) unless replacement is

7-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |