|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-249-34&P

c. Remove eight thrust washers (51.2 and 51.7),

eight spacers (51.3 and 51.6), 112 rollers (51.4), and

four pinions (51.5).

NOTE

Because the four pinions are a matched set,

place each pinion and its component parts

in a separate container. If any one of the

pinions must be replaced, the whole set is to

be replaced with a matched set of four

pinions.

7-58. Cleaning

Refer to paragraph 5-2 for cleaning recommendations.

7-59. Inspection and Repair

Refer to paragraph 5-3, for inspection and repair

recommendations.

7-60. Repair Standards

repair standards.

NOTE

Chill spindles (51.1) in dry ice for

approximately 1 hour prior to installing

them in the carrier.

a. Grease the bore of a pinion (51.5) with a

liberal amount of oil-soluble grease.

b. Install a spacer (51.3) and thrust washer

(51.2) on one end of pinion (51.5).

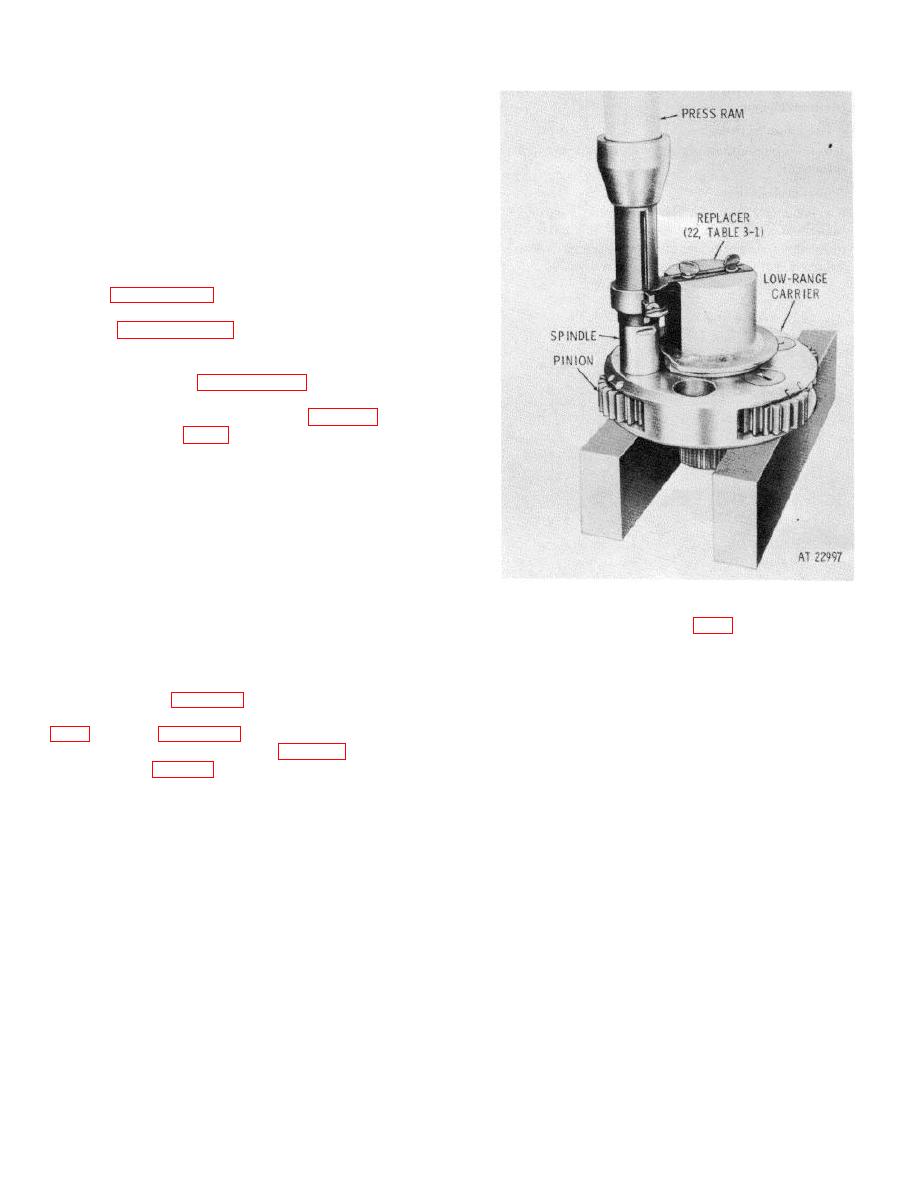

Figure 7-14. Installing spindle into low-range planetary:

c. Install 28 rollers (51.4) around the bore wall

carrier.

of pinion (51.5).

d. Install another spacer (51.6) and another

to 0.090 inch below the pin bore surface of the carrier,

thrust washer (51.7) on the other end of pinion (51.5).

and stake carrier metal over the end of the pin to retain

e. Install the pinion with rollers, spacers and

it.

thrust washers into the carrier. Using an alinement tool

h. Install the remaining three pinions (51.5),

of replacer (22, table 3-1), aline the pinion and its

each with its associated parts, into carrier (52), and pins

component parts with the spindle bore in carrier (52,

(51.8), as described in a through g, above.

f.

Using replacer (22, table 3-1), install a

pinion spindle (fig. 7-14). Press the spindle flush with, to

0.010 inch below, the spindle bore surface of the carrier.

7-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |