|

|||

|

|

|||

|

Page Title:

Table 7-12. Soldering of Hook Leads |

|

||

| ||||||||||

|

|

TM 750-245-4

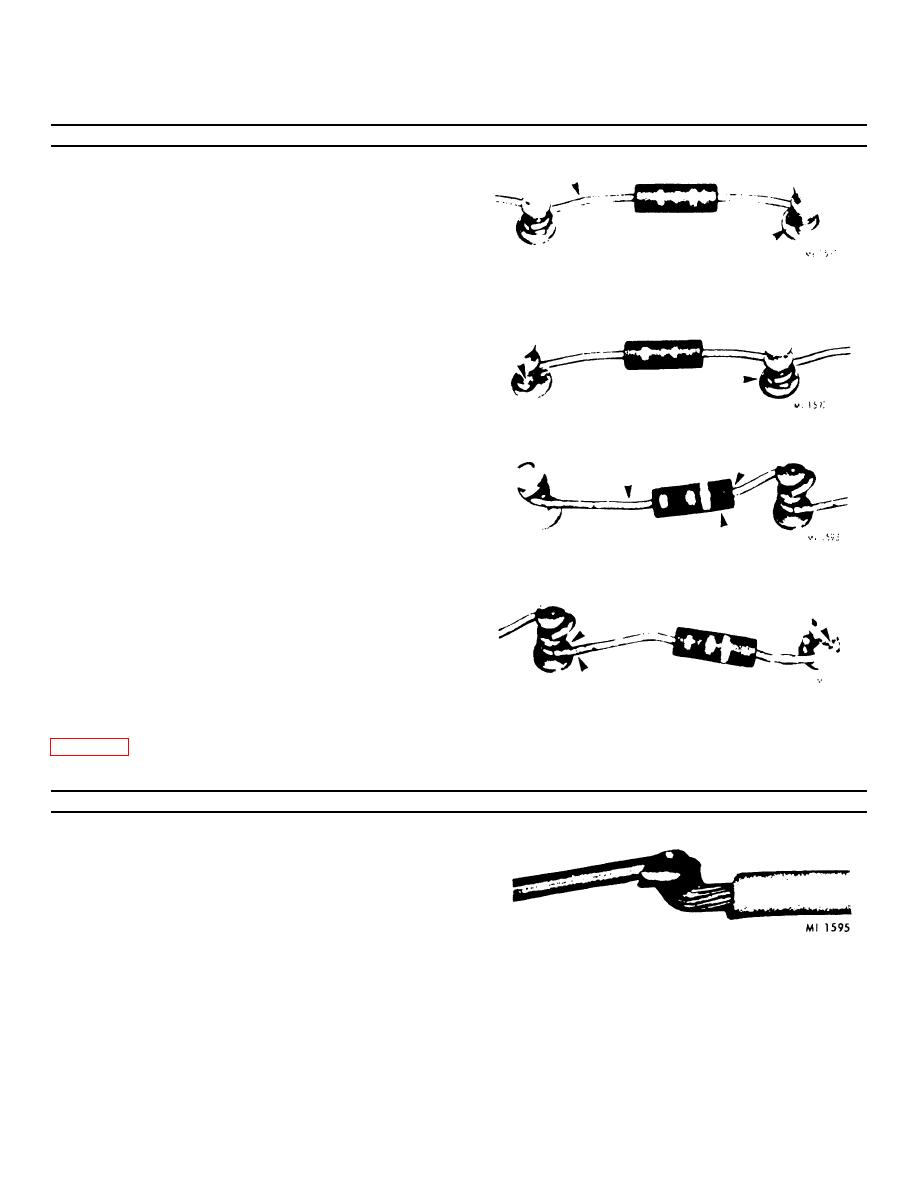

Table 7-11. Soldering of Components - Continued

Inspection criteria

Illustration

MINIMUM ACCEPTABLE

Component leads from a slight loop to offset

component body from terminal centerline

Slight "dimple" adjacent to lead or terminal post

Solder is maximum but lead is well defined

REJECT

Lead and terminal under tension. Insufficient

slack

Component not flush with board

Lead bent at component body

Very poor quality throughout installation

Solder has not wet terminal

Hole adjacent to terminal

Component lead shows evidence of con-

tamination - solder has not wet lead

7-21. Soldering of Hooked Leads

Table 7-12. Soldering of Hook Leads

Inspection criteria

Illustration

ACCEPTABLE

Leads are clean and well tinned

Solder adequate, not wicked

Hooks are well formed

7-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |