|

|||

|

|

|||

|

Page Title:

Section IV. COMPARISON STANDARDS |

|

||

| ||||||||||

|

|

TM 750-245-4

allowed on system drawings and as permitted by

m. Dewetting. (Separation of printed circuit from

Department of the Army publications for system

circuit board.)

material.

n. Insufficient solder.

r. Plated through holes not filled with continuous

o. Visible bare primary conductor within the solder

solder plug.

joint area.

s. Pads connected by plated-through holes and

p. Clinched leads resulting in a reduction of the

eyelets connecting pads on multi-layer boards or double

required spacing between conductors.

sided printed circuit boards show evidence of failure to

q. Splicing of conductors is prohibited, except as

wet the metallic surfaces.

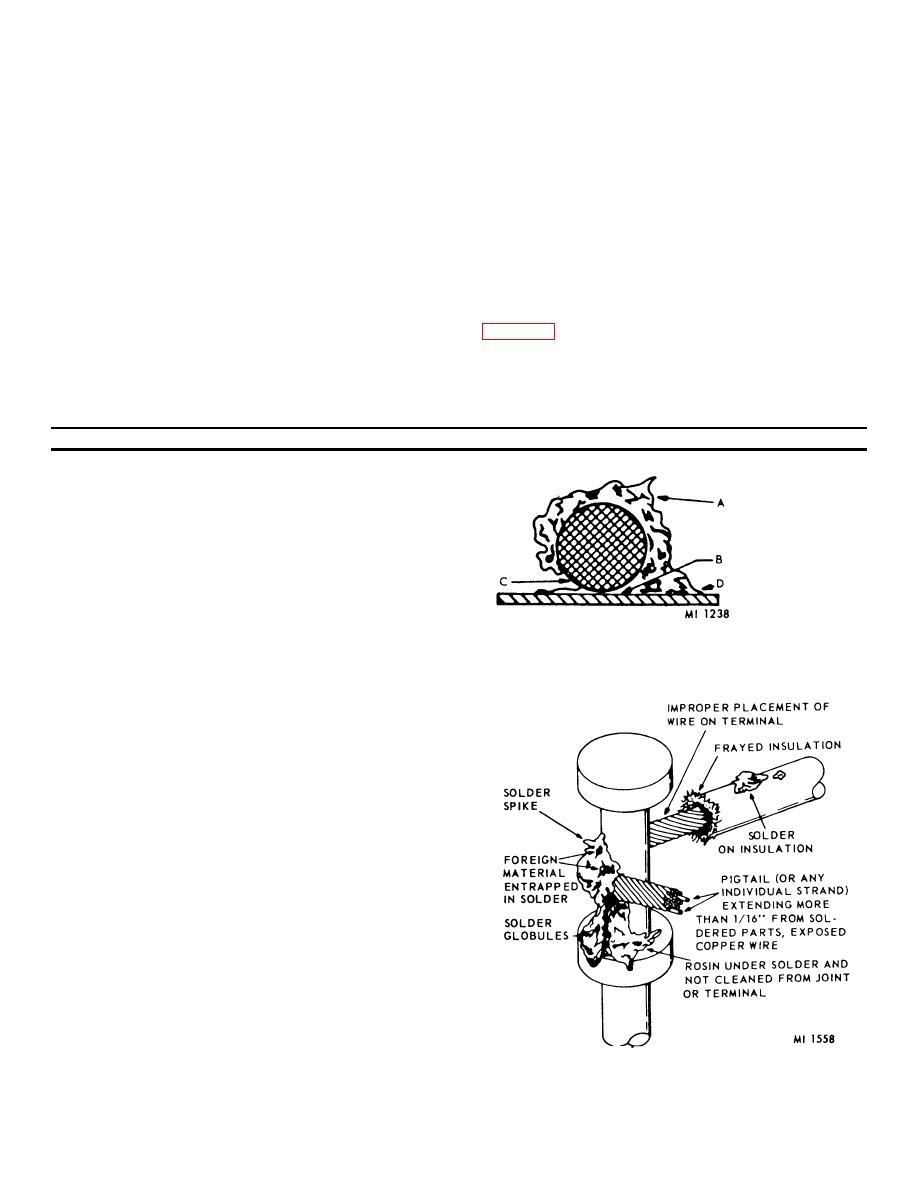

Section IV. COMPARISON STANDARDS

7-12. General

and bad workmanship. The remaining tables show

This section provides a visual guide for inspection of

actual repair procedures with applicable inspection

solder connectors.

These show the acceptable,

criteria.

minimum acceptable, and reject inspection criteria.

Table 7-3. Workmanship

Indicator

Illustration

Cold or underheated solder joint

A. Solder has a chalky appearance, lacks metallic

luster, generally presents a rough, piled-up

appearance.

B. Solder has not bonded terminal and wire

together.

C. Solder coverage not complete.

D. Improper filleting indicating insufficient flowing

and watting action.

Improper soldering

7-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |