|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 750-245-4

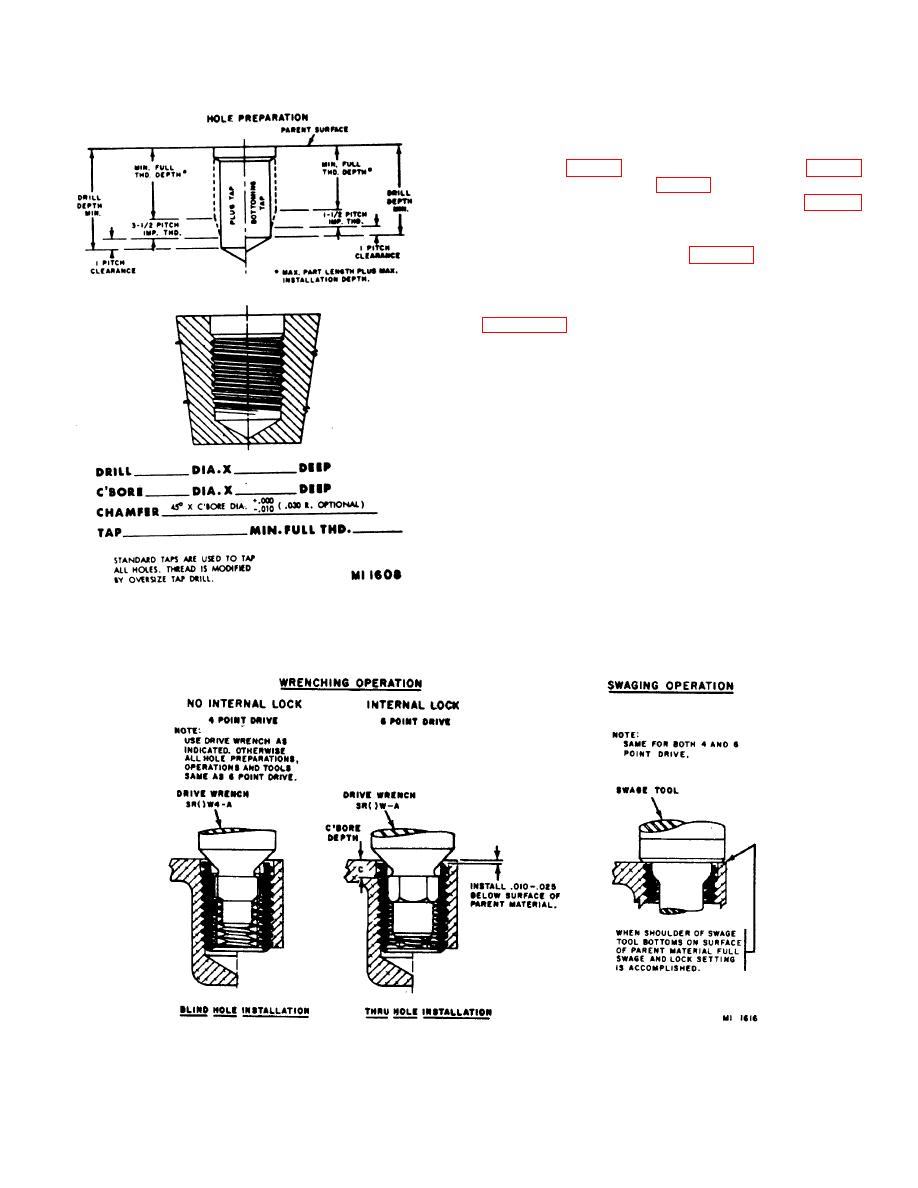

4-14. Key Type Insert Installation

The installation of key type inserts is very simple and

can be accomplished without special tools. After hole

preparation (fig. 4-2) or old key insert removal (fig. 4-4)

screw the new key insert (fig. 4-5) to a depth of 0.010 to

0.030 below the surface. Drive the keys down (fig. 4-6)

to set and lock the insert.

4-15. Blind Nut Assemblies (Fig. 4-6)

The inspector will have to perform an in-process

inspection of blind nut installations because in most

cases they cannot be inspected after repair. Refer to

installation of blind nuts.

4-16. Hardware Inspection

All hardware shall be of the proper size, type, shape,

length, and thread. There shall be no burrs, corrosion or

physical damage. Washers shall have correct pileup.

Screws shall protrude at least one complete thread from

the surface of the hex or clinch nut. Screws shall not

protrude more than two complete threads from the

surface of the hex or clinch nut when there is a

possibility of shorting, mechanical interference, or safety

hazard.

a. Threaded Components (Bolts, Screws, and

Nuts).

(1) Threads shall not be crossed or stripped.

Figure 4-2. New hole preparation.

(2) Bolt shanks shall not be galled.

Figure 4-3. Swaging type insert installation.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |