|

|||

|

|

|||

|

Page Title:

"Not Go" Gages for Screw Threads |

|

||

| ||||||||||

|

|

TM 750-245-4

checks the maximum limit of a threaded plug and the

minimum pitch diameter of the screw. The tolerance is

minimum limit of the threaded hole.

plus but may be minus for the reason given in the

preceding subparagraph.

a. Pitch Diameter. The pitch diameter of W and X

"Go" plug gages is the same as the minimum pitch

diameter of the threaded hole or nut. The Tolerance is

4-10. Thread Form on Gages

plus for plugs. The pitch diameter of the W and X "Go"

ring gages is the same as the maximum pitch diameter

and ring gages. The crest of the thread on "Not Go"

of the screw. The tolerance is minus for rings.

plug and ring gages is partly removed to insure proper

contact. There is also a clearance groove at the root of

b. Major and Minor Diameters.

The major

"Not Go" plug and ring gages to insure pitch diameter

diameter of the "Go" plug gage is the same as the basic

contact. The "Go" plug and ring gages may have

major diameter, with a plus tolerance. The minor

clearance grooves at the roots to facilitate grinding and

diameter of the "Go" ring gage is the same as the

lapping.

minimum minor diameter of the nut or tapped hole, with

a minus tolerance.

4-11. Truncated Setting Plugs

a. The major diameter of the full portion of the

"Go" setting plug is that of a full American National

form, based on maximum pitch diameter of the screw.

The tolerance is plus. The major diameter of the

Truncated portion of the "Go" setting plug is that of a full

American National form minus one-third the basic

thread depth with a minus tolerance.

b. The major diameter of the full portion of the

"Not Go" setting plug is the same as that of the "Go"

plug of the same nominal size, except that the

truncation from a theoretical vee should not be less than

0.058 times pitch. The latter condition might arise in the

case of fine pitches and especially wide tolerances. The

tolerance is minus. The major diameter of the truncated

portion of the "Not Go" setting plug is that of a full

American National form minus one-third the basic

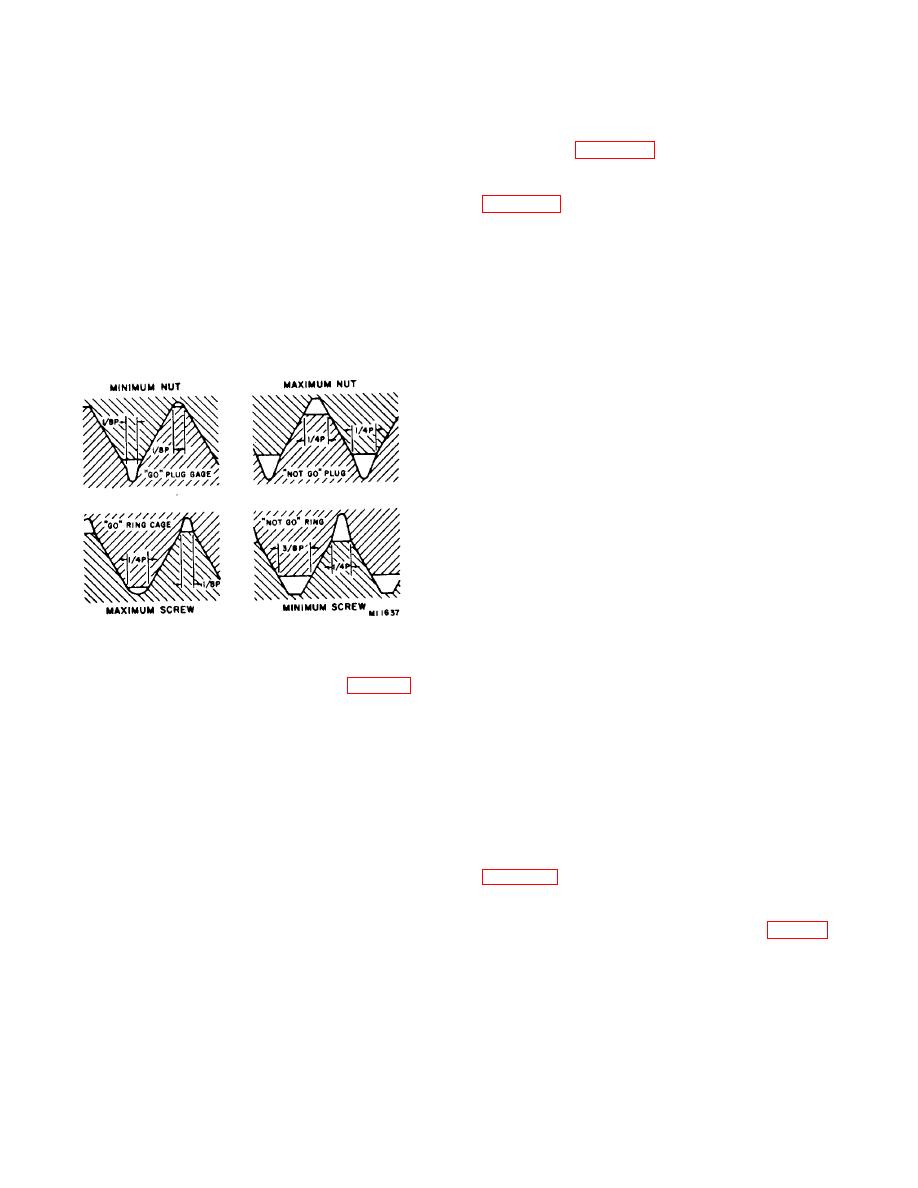

Figure 4-1. Screw thread check.

thread depth, with a minus tolerance.

4-9. "Not Go" Gages for Screw Threads (Fig. 4-1)

4-12. Inserts

A "Not Go" thread gage which checks the pitch diameter

a. The inspector should familiarize himself with the

only, usually meets practical requirements. The "Not

repair procedures, as in-process inspection should be

Go" gage checks the minimum limit of a threaded plug

performed to insure a good insert installation. Refer to

and the maximum limit of a threaded hole.

the system documentation to determine if such repairs

a. Pitch Diameter Plug Gage. The pitch diameter

are authorized and the number of times the insert can

of a "Not Go" plug gage equals the maximum pitch

be replaced.

diameter of the threaded hole or nut. The tolerance is

b. There are various types of inserts which can be

minus but may be plus. All gages used for the

used to repair components which have attaching hole

production of screw threads, and "Go" gages for

threads stripped. New hole preparation as shown in

inspection, should be within the extreme limits of the

product. However, to avoid needless controversy about

installation.

parts close to "Not Go" limits because of possible small

differences in gage sizes, the pitch diameter tolerances

on all "Not Go" gages used for final inspection and for

4-13. Swaging Type Insert Installation (fig. 4-3)

inspection of purchased products, may be outside of the

The installation of swaging type inserts requires special

product limits is specially authorized.

tools. A drive wrench is used to install the insert into the

tapped hole. After the insert is installed to the proper

b. Pitch Diameter Ring Gage. The pitch diameter

depth a swage tool is then used to lock the insert in

of the "Not Go" thread-ring gage is the same as the

place.

4-3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |