|

|||

|

|

|||

|

Page Title:

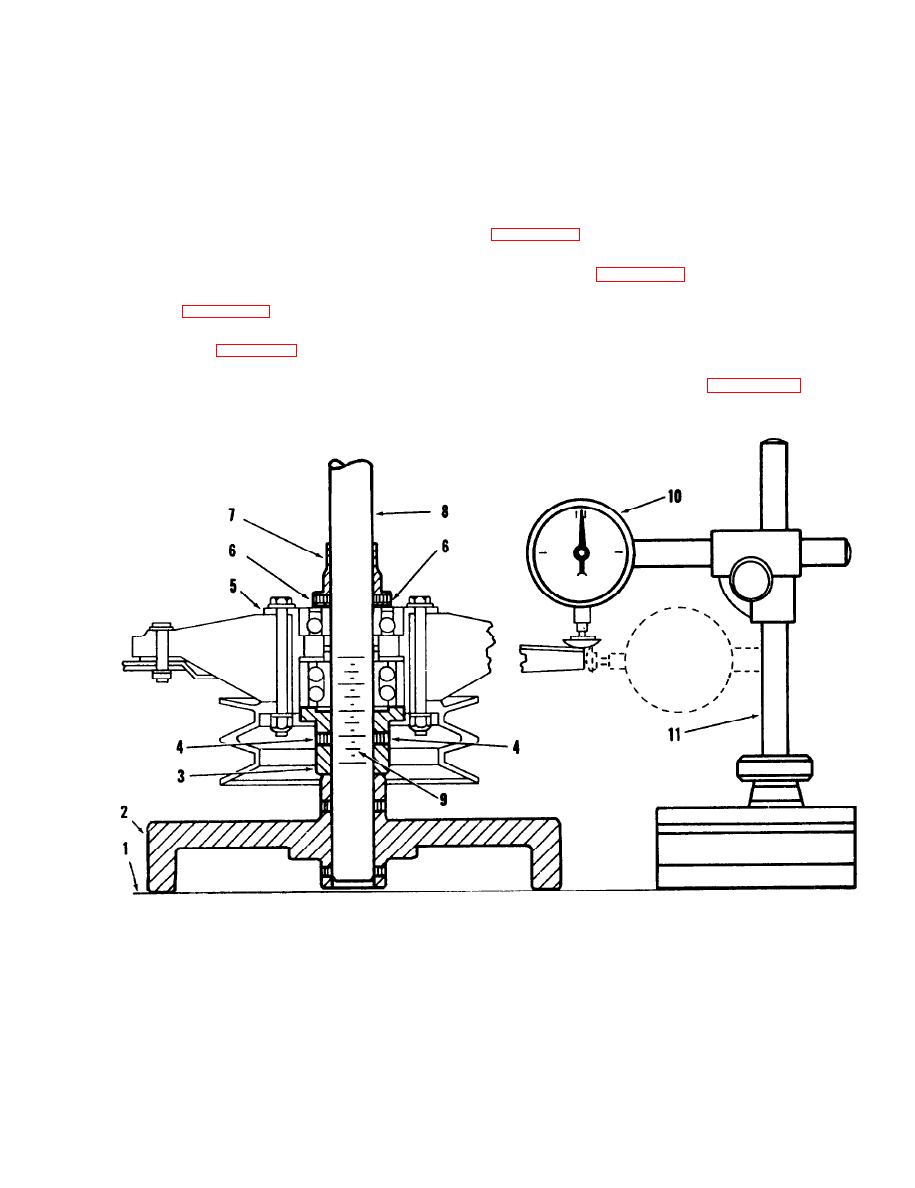

Figure 4-15. Setup for OH-13 and TH-13 Helicopter Engine Fan Assembly Track and Concentricity Check. |

|

||

| ||||||||||

|

|

TM 55-4920-201-14

4-32. OH-13 and TH-13 Engine Fan Assembly

pulleys downward, over top of arbor, insuring that

Track and Concentricity Check. (See figure 4-

pilot bushing (3) flange enters fan hub bearing

15).

sleeve and seats squarely on fan bearing outer race.

a. Clamp fixture assembly (2), recessed side

e. Install sleeve (7), flange downward, over

top end of arbor, and seat firmly on inner race of

downward, on surface plate (1) or other firm

support surface.

fan bearing. Lock sleeve in this position by

moderate and uniform tightening of two sleeve

b. Install pilot bushing (3), flange upward,

setscrews (6), using 3/32-inch hex wrench (2,

on balancing arbor (8) so that bottom of bushing

hub aligns approximately with P-inch position on

arbor scale (9). Lock bushing in this position by

f. Install 1/2 inch mushroom point on dial

indicator (10, figure 4-15) and adjust height gage

moderate and uniform tightening of two pilot

bushing setscrews (4), using 3/32-inch hex

assembly (11) to read track or concentricity

variations as required. Rotate fan to determine

wrench (2, figure 1-18).

range of variations.

c. Install lower end of arbor in hub of fix-

g. For track and concentricity tolerances and

ture assembly (2, figure 4-15) so that bottom of pi-

application of corrections, refer to applicable

lot bushing (3) rests on top of fixture assembly hub.

Do not lock fixture hub setscrews.

helicopter manual. (Refer to appendix A).

d. Carefully install engine fan assembly (5),

9. Arbor scale

5. Engine fan assembly

1. Surface plate

10. Dial indicator (7HEL055

6. Sleeve setscrew

2. Fixture assembly (2532,

kit)

7. Bushing (2530, 7HEL053

7HELO53 kit)

11. Height gage assembly

kit)

3. Pilot bushing (2533,

(7HEL055 kit)

8. Balancing arbor (2516,

7HEL053 kit)

7HEL053 kit)

4. Pilot bushing Setscrew

Figure 4-15. Setup for OH-13 and TH-13 Helicopter Engine Fan Assembly Track

and Concentricity Check.

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |