|

|||

|

|

|||

|

Page Title:

Figure 4-38. Cylinder Liner Ridge Due to Wear |

|

||

| ||||||||||

|

|

TM 55-1930-208-24

4-12. CYLINDER LINERS- Continued.

c. Inspection - Continued.

(2) The liner flange must be smooth and flat on both the top and bottom surfaces. Check for cracks at the

flange. The liner insert must also be smooth and flat on the top and bottom surfaces. Replace liner if there

is evidence of brinelling.

(3) A used cylinder liner must be honed for the following reasons

:

NOTE

Do not modify the surface finish in a new service liner. Since the liner is properly finished at the factory,

any change will adversely affect the seating of the piston rings.

(a) Break the glaze due to the rubbing action of the piston rings which results after long periods of operation.

Unless this glaze is removed, the time required to seat new piston rings will be lengthened.

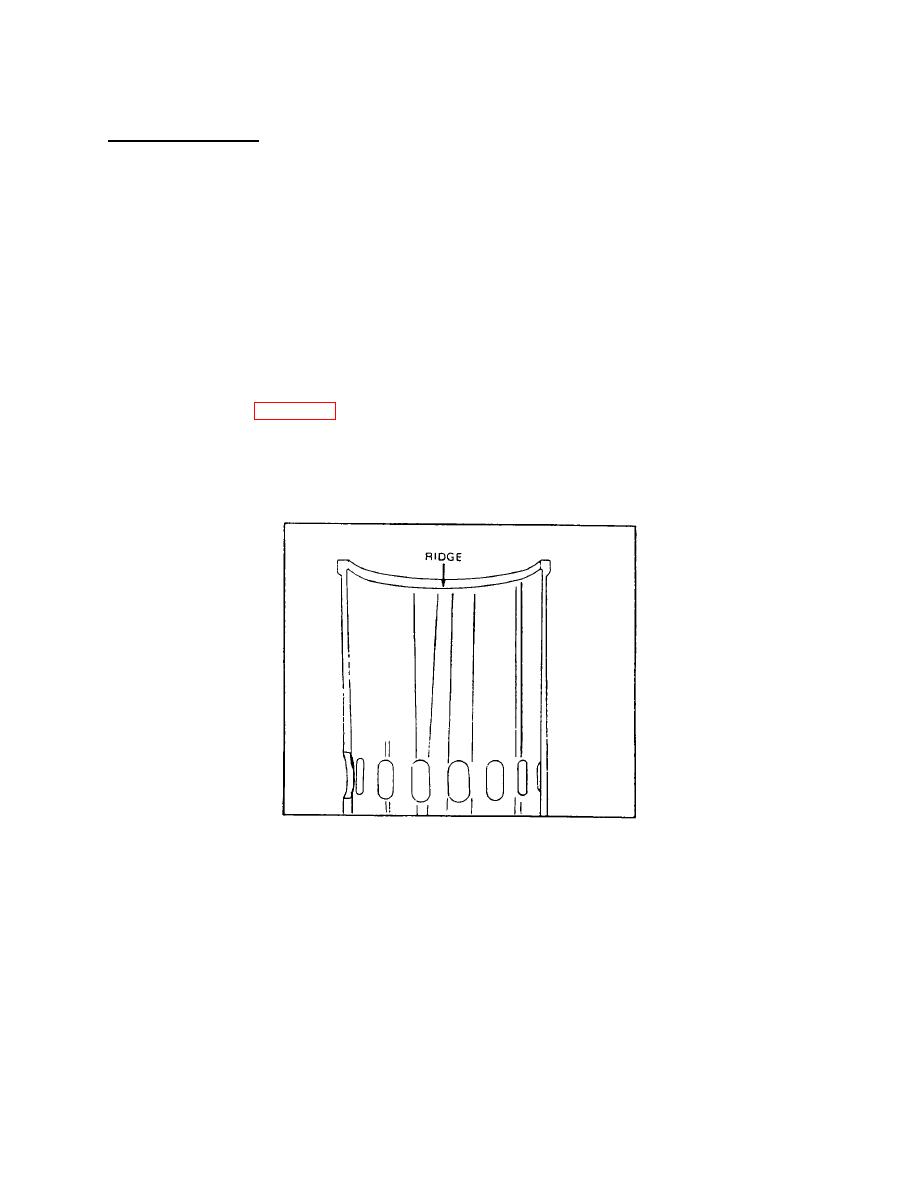

(b) Remove the ridge (figure 4-38) formed at the top by piston ring travel. Otherwise, interference with thetravel

of the new compression rings may result in ring breakage.

(c) The hone J5902-01, equipped with 120 grit stones J5902-14, should be worked up and down the full length of

liner a few times in a criss-cross pattern that produces hone marks on a 45 axis.

Figure 4-38 .

Cylinder Liner Ridge Due to Wear .

(d) After liner has been honed, remove it from the fixture and clean it thoroughly. Then dryit with compressed

air and check the entire surface for burrs.

4-48

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |