|

|||

|

|

|||

|

Page Title:

Figure 3-82. Testing Cam Follower Spring. |

|

||

| ||||||||||

|

|

TM 55-1930-208-24

3-39. VALVE OPERATING MECHANISM - Continued.

c.

Inspection Continued.

(3)

Inspect push rods for distortion and excessive wear.

(4)

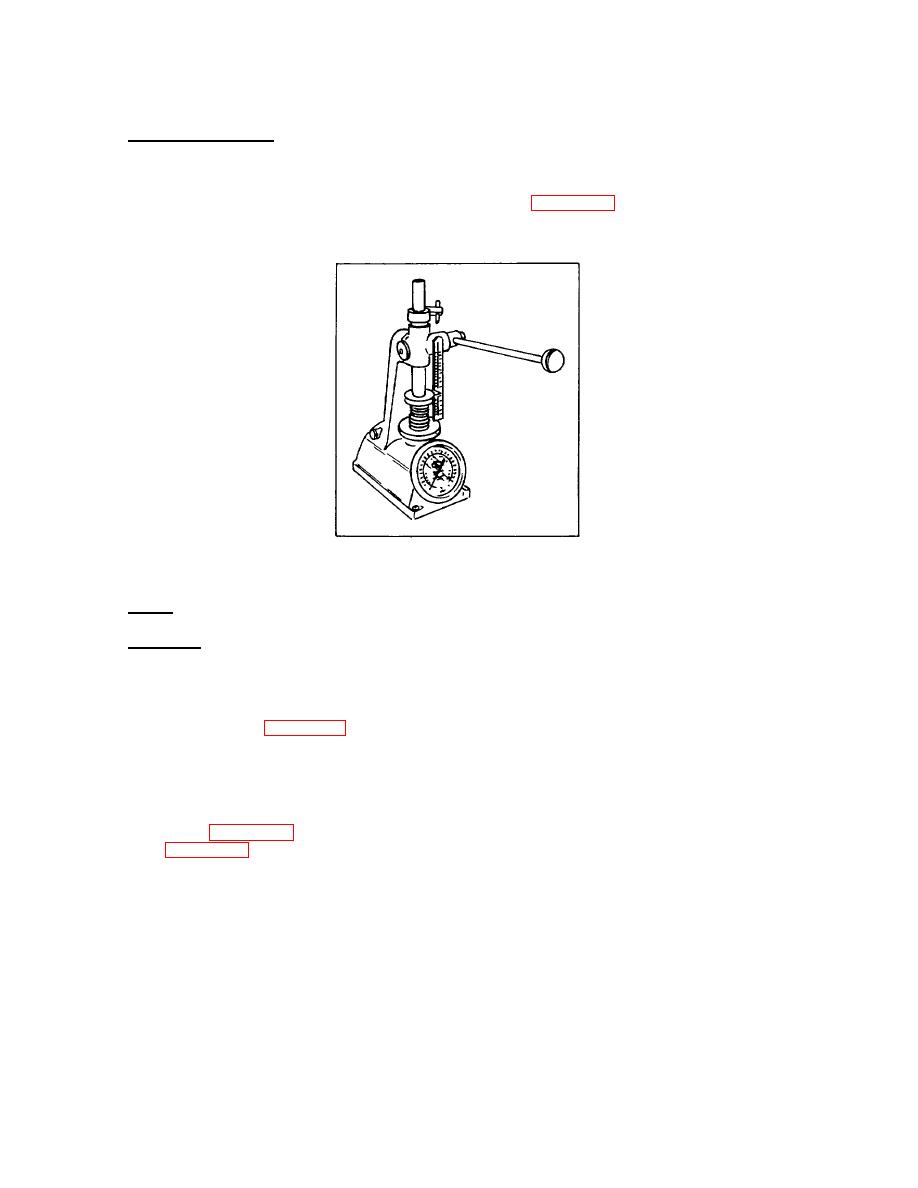

Install cam follower spring in spring tester J22738-02 (figure 3-82) and check the spring load. Replace a

spring when a load of less than 172 lbs (72.98 kg) will compress it to a length of 2.125 inch.

Figure 3-82. Testing Cam Follower Spring.

d.

Repair. Repair is limited to replacing cam roller, roller pin, and other defective parts.

e.

Installation.

NOTE

If new cam follower assemblies are to be installed, remove the preservative by washing with clean

lubricating oil (item 12, Appendix C) and wipe dry. Do not use fuel oil.

WARNING

Wear asbestos gloves to avoid serious burns when handling heated part.

(1)

Refer to figure 3-80. Before cam followers are installed, immerse them in clean lubricating oil (item 12,

Appendix C) (heated to 100-125 or 38-52 ) for at least one hour to ensure initial lubrication of the

F

C

cam roller pins and bushings. Rotate cam rollers during the soaking period to purge any air from

bushing-roller area.

3-140

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |