|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

surface of the commutator with

a

power-driven

undercutting

tool (fig. 34).

If a power-

driven tool is not available,

the mica may be undercut by hand,

Should small burs extend be-

yond the grooves, they can be

removed by running a three-cor-

nered scraper along the bottom

edge of the groove.

Polishing

commutator.

After

(3)

the mica has been undercut, re-

move all copper and mica par-

ticles with compressed air.

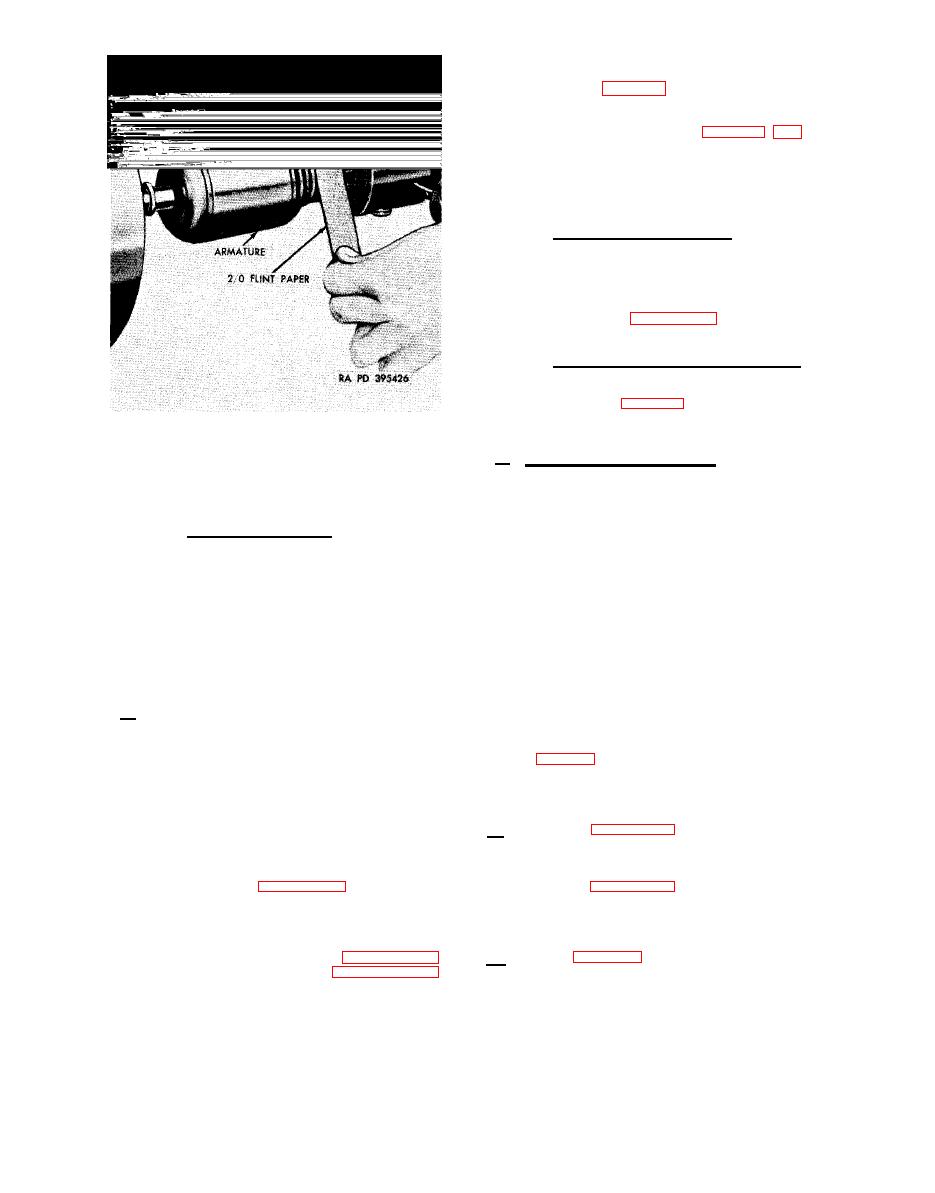

Polish the commutator in a lathe

2/0 sandpaper as illus-

with

trated in figure 36, with the

armature rotating at 1500 rpm.

Checking armature eccentricity.

(4)

Setups dial indicator gage and

measure the runout of the com-

mutator (fig. 31). Total run-

out should not exceed 0.003-

inch.

Polishing commutator

with sandpaper.

f. Insulating Field Coils.

Apply as

many coats of insulating varnish as neces-

Note. When a cut is started,

sary to properly insulate the field coils.

it should be carried across en-

Allow each coat to dry Until "tacky" before

tire surface without stopping.

applying another coat.

After sufficient

After re-

coats have been applied, place the field

(2)

Undercutting mica.

coils in a drying oven and bake for two

surfacing the armature, under-

hours at a temperature of 193F (77C).

cut mica to l/32-inch below the

Section IV.

ASSEMBLY

28. General

of the starter and for part identification

a.

The instructions covering assembly

of the starter are almost identically the

reverse of those covering disassembly.

When one part of the brush parts kit -

Therefore, the following assembly proce-

5702664 (fig. 51) requires replacement,

dures, for the most part, will be refer-

the entire kit should be used.

enced to the illustrations appearing under

disassembly.

When this occurs, the in-

30. Brushes

structions appearing with each referenced

illustration should be performed in the

Refer to figure 25 for instructions

a.

reverse order from which they are given.

covering installation of square bushing

For example, callout letters A, B, C, and

and associated parts.

D indicate the sequence of the disassembly

b.

steps provided with figure 23.

Assembly

Refer to figure 24 for instructions

-

may be accomplished by performing these

covering installation of brushes.

i.e., D, C, B,

steps in reverse order;

and A.

a . Refer to figures 23 and 22 for in-

b.

The exploded views,

structions covering assembly of the commu-

through 50, are included in Appendix II

tator end head assembly.

of the manual to provide a visual refer-

ence to the relationship of the components

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |