|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

e. Block Mating Surfaces. Check top machined

(2) Check ID of the sleeve against limits

specified in repair and rebuild standards (para 3-179).

surfaces of block with straight edge and feeler gage. If

Measurements shall be made at middle, and skirt of

warped, distorted or uneven replace block.

f. Expansion Plugs. Inspect all expansion plugs

sleeve. Replace any s worn beyond specified limits.

for evidence of coolant leakage. Replace all plugs that

are defective.

NOTE

g. Miscellaneous Parts. Inspect main bearing cap

Refer to paragraph 3-2.c. for sleeve

screws, washers, and all pipe plugs. Check for

removal. If any sleeve requires removal

damaged threads, nicks, burs, and other unserviceable

perform steps 3 and 4 below.

conditions. Replace all unserviceable parts.

3-5. Repair

(3)

Discard preformed packings and crevice

Repair of the cylinder block is limited to general

seals.

procedures as outlined in paragraph 2-7. Any defect, or

(4) Using block gage (24, fig. B28) cylinder

measurement outside the tolerances listed in paragraph

counterbore and bore against limits specified in repair

and rebuild standards (13-175).

Replace block if

measurements are beyond specified limits.

36. Assembly

a. Camshaft Bushings. Refer to paragraph 3

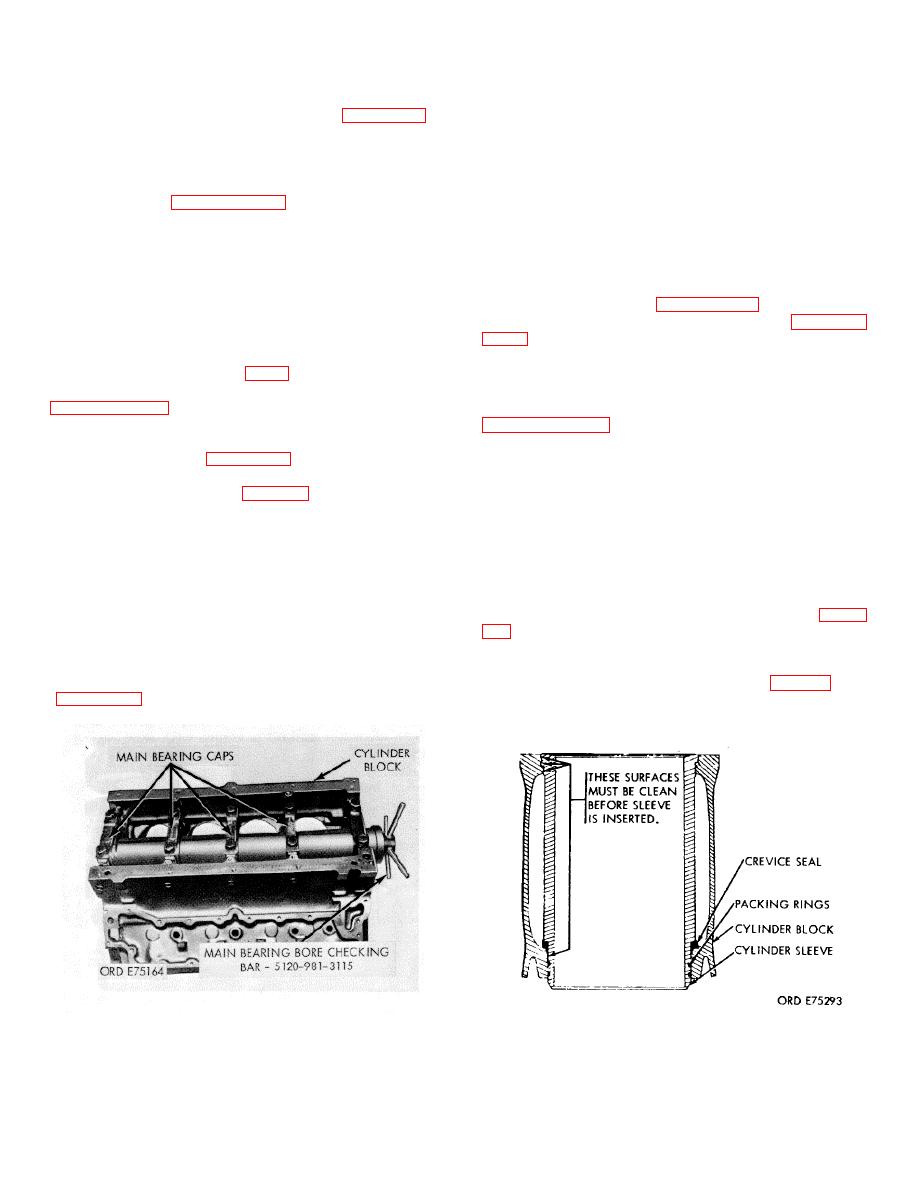

(1) Install and tighten bearing caps. Refer to

2.b., and reverse the order of removal.

b. Pipe Plugs. Install all pipe plugs. Refer to

(2) Check

bearing

bores

horizontally,

vertically, and diagonally against limits specific repair

sealing tape or lead solder to prevent leakage.

and rebuild standards (para. 3-175).

c. Cylinder Sleeves.

(3) Check alignment of bore using bearing bore

alignment checking bar (19, fig. B-28)

NOTE

NOTE

Before installing sleeves insure that

Inspect bar for run-out and OD prior to

each sleeve protrusion is 0.004 to 0.006-

use. Bar must be 3.7510-3.7506-inch

inch.

OD and straight within 0.0005 in full

length. Bar must pass through all bores

(1) Install crevice seal ring on machined

and turn freely. Replace any cap that

surface above packing ring grooves, as shown in figure

prevents free passage and turning.

(2) Lubricate packing rings with light coating of

d. Tappet Bores. Check valve and injector pet

OE-10 lubricant.

bores against limits specified in repair rebuild standards

(3) Roll each ring into grooves (fig. 3-4) and

straighten using ring mold mark as a guide.

Figure 3-3. Main bearing bore alignment check

Figure 3-4. Cylinder sleeve sells installation

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |