|

|||

|

|

|||

|

Page Title:

INSTALLATION OF OIL PUMP ASSEMBLY, OIL PUMP TUBES, AND OIL PAN |

|

||

| ||||||||||

|

|

connecting rod being installed is at

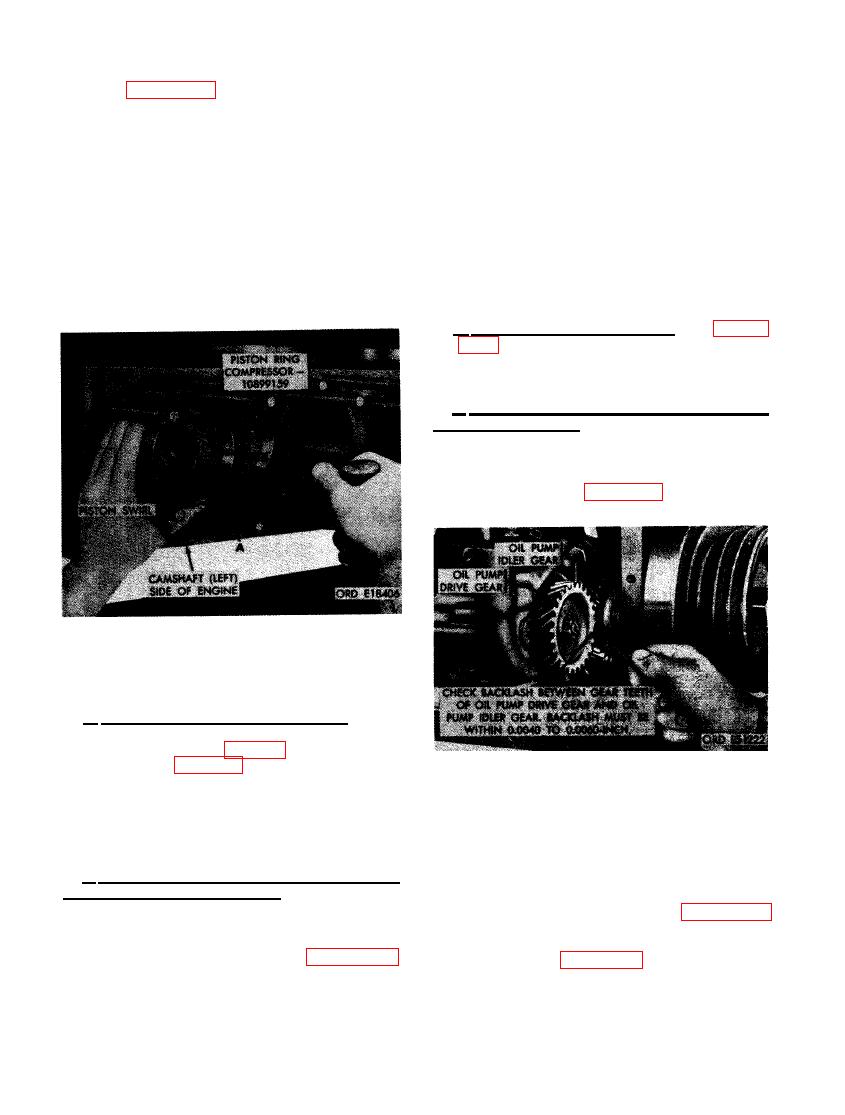

(2) Figure 480. (A) Position piston ring

bottom center. The remaining piston

compressor- 10899159 over cylinder

and connecting rod assemblies can be

liner with small inside diameter end

installed in a sequence of No. 6, No. 2

toward liner. (B) Install connecting rod

and 5, and 3 and 4, to prevent unneces-

through compressor. Guide piston skirt

sary crankshaft rotation.

through compressor and gently tap the

piston with a wooden hammer handle

(2) Install remaining connecting rod caps

(or other suitable tool) until top piston

with assembled connecting rod sleeve

ring enters cylinder liner. Remove

bearings as directed in paragraph b

piston ring compressor -10899159. With

above.

the aid of an assistant to guide connect-

ing rod, continue to tap piston until

bearing seats on crankshaft journal.

BLY, OIL PUMP TUBES, AND OIL PAN

a. Install Oil Pump Assembly. Refer to fig-

ure-s 281 and 282 and reverse the sequence of

illustrations and instructions to install the oil

pump assembly.

b. Check oil Pump Drive Gear and Oil Pump

Idler Gear Backlash.

(1) Check oil pump drive gear and oil

pump idler gear backlash following in-

structions on figure 481.

NECTING ROD ASSEMBLY USING PISTON

RING COMPRESSOR - 10899159.

b. Install No. 1 Connecting Rod Cap. Install

the-connecting rod cap and sleeve bearings on

No. 1 connecting rod (fig. 284). The location

number on cap (fig. 343) must correspond to

the number on connecting rod and numbers must

be toward the camshaft side of the engine.

GEAR AND OIL PUMP IDLER GEAR

Secure the cap to the rod by installing two con-

BACKLASH.

necting rod bolts. Tighten the connecting rod

bolts to a torque of 800 pound inches.

(2) When oil pump drive gear and oil pump

c. Install Remaining Piston and Connecting

idler gear backlash is not within spec-

Rod Assemblies and Rod Caps.

ifications, remove oil pump assembly

following instructions for figures 281

(1) Install remaining piston and connecting

and 282.

rod assemblies in the same manner

following instructions for figure 480.

(3) Refer to figure 304 and remove front

Rotate crankshaft so that connecting

main bearing cap with assembled oil

rod journal for respective piston and

pump idler gear.

306

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |