|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

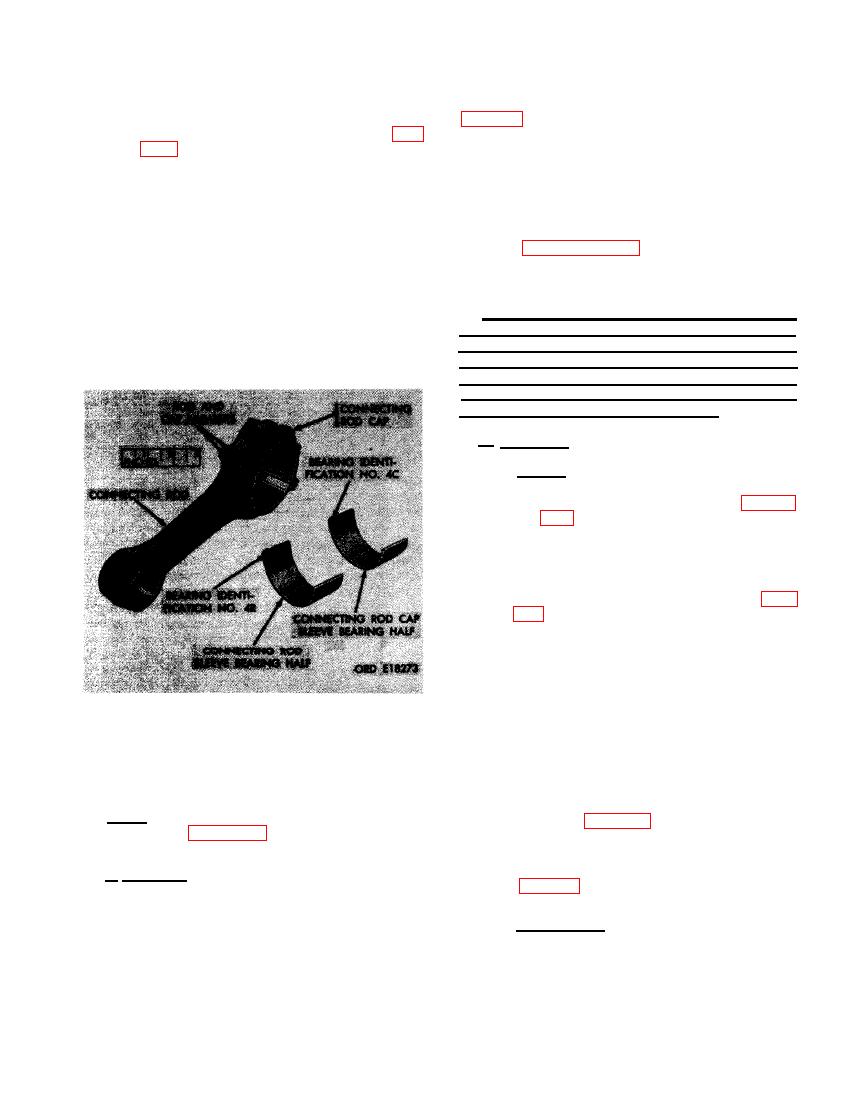

and cap for cylinder No. 4. Connecting

ring lands. Clean oil holes in oil rings and oil

rod sleeve bearings are also marked

ring grooves. Remove carbon from oil holes

to indicate their locations. The con-

necting rod sleeve bearing halves (fig.

23 drill (0.154-inch). Remove carbon from

cavity and swirl inlet in piston head. Clean

marked "4R" for the half that fits into

carbon from piston pins and bores with crocus

the rod, "4C" for the bearing that fits

cloth dipped in dry-cleaning solvent or mineral

into the cap. The identification marks

spirits paint thinner. Clean connecting rod

appear inside the alinement tang of

sleeve bearing halves with cloth dipped in dry-

each bearing half. If the connecting rod,

cleaning solvent or mineral spirits paint thinner.

cap, or bearing markings are oblit-

Refer to paragraph 152 for general cleaning

erated, mark with a grease pencil for

instructions for cleaning connecting rods and

installation in their original positions.

caps.

Install rod cap on connecting rod using

the two connecting rod bolts after con-

Caution: Use goggles, rubber gloves, and

necting rod sleeve bearing halves have

rubber apron when cleaning parts in carbon

been removed.

removing compound. Provide adequate ventila-

tion. Avoid inhalation of fumes and skin contact.

If compound is splashed on skin, flush with

water and wash with alcohol. Alcohol containing

2 to 3 percent camphor is preferred.

b. Inspection.

(1) Piston. Inspect piston for cracks, burned

piston ring lands, and damaged piston

skirt. Thoroughly inspect piston. Fig-

ure 344. (A) Inspect general conditon of

No. 1 and No. 2 compression ring

grooves in piston. Place a 0.1125-inch

diameter pin on each side of piston in

tapered ring groove as shown. Refer

to repair and rebuild standards (par.

tance between pins using a micrometer.

Measurement should be from 4.2920 for

used piston to 4.3040 for new piston.

Replace piston when measurement is

below 4.2920 or the tapered ring groove

is worn beyond limits specified. (B)

Check condition of the spherical com-

bustion chamber at top of each piston

BEARING AND CONNECTING ROD IDENT-

using a new piston for comparison.

IFICATION NUMBER LOCATIONS.

Chamber must not be burned or dis-

torted. (C) Check piston pin bore against

limits specified in repair and rebuild

Note. The key letters shown below in paren-

standards (par. 292). Replace piston and

theses refer to figure 322 except where other-

piston pin when piston pin bore is over-

wise indicated.

size. (D) Check piston against limits

specified in repair and rebuild standards

a. Cleaning. Clean piston (YY), rings (TT,

UU, and VV), piston pin (XX), and retaining

rings (WW) by soaking in carbon removing com-

pound (MIL-S-12382 (ORD) type 1). Do not des-

(2) Piston rings. Inspect compression rings

(TT and UU) and oil control rings

troy or remove connecting rod or bearing loca-

(VV) for scuffing, scoring, chipping,

tion markings. Scrape remaining carbon de-

posits from piston ring grooves with a scraper

scratches, or abrasions. Pay particular

attention to rings which were found to

or a broken piston ring. Do not scratch or gouge

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |