|

|||

|

|

|||

|

Page Title:

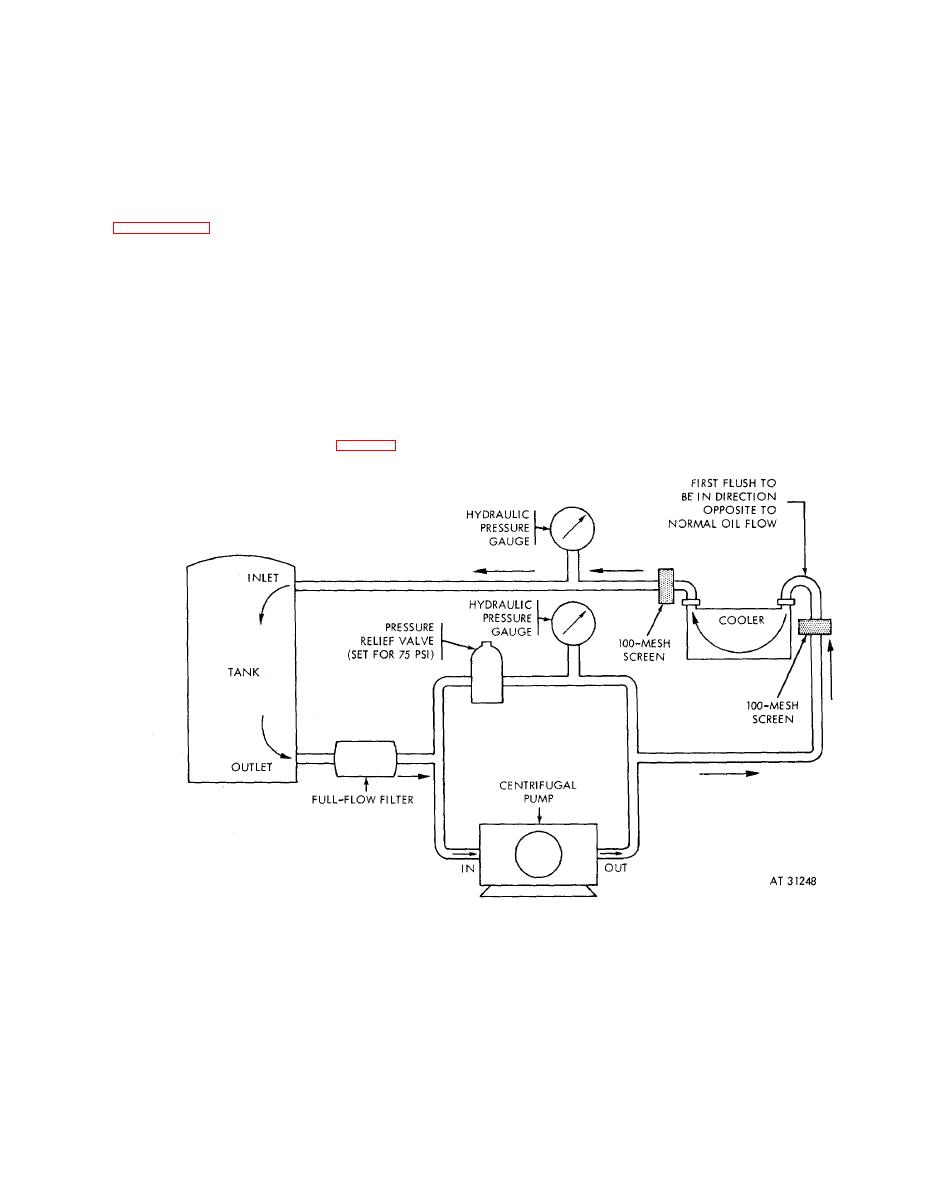

Figure 6-224. Oil cooler cleaning equipment setup-schematic diagram. |

|

||

| ||||||||||

|

|

rubber

plug

into

bypass

opening

in

the

valve

c.

Cleaning.

housing. Reinstall valve into the valve housing so

(1) External surfaces of coolers may be

that the valve bears up against the rubber plug.

cleaned using oil cooler cleaning tool - 2940-927-

Note. Use only cleaning solutions recom-

3303.

Clean

thoroughly

and

blow

dry

with

mended in these instructions or ones satisfactory

compressed air at 15 psi pressure.

for aluminum. Many solutions satisfactory for

(2) To clean the interior of an oil cooler

cleaning copper or copper nickel coolers are

assembly core, the pump equipment shown in

highly corrosive to aluminum and if used will

result in the destruction of the cooler. If

for the cleaning procedure. There are several

equipment has been previously used with any

possible arrangements of the equipment

other cleaning solutions, it should be thoroughly

depending upon equipment availability and

washed out and flushed with the recommended

versatility. If provision can be made for flushing

solution.

pump lines, one set of pump equipment can be

Warning; Cleaning

solvents

and

solvent

used with four storage tanks to provide the

required four solutions for rinsing, cleaning, a n d

cleaning compounds are toxic and flammable

and must be used only in a well ventilated room.

flushing. If such provisions cannot be made

Take adequate safe guards for fire prevention in

conveniently, four sets of pump equipment are

work area. Use protective clothing and

avoid

required.

contact of these solutions with the skin.

(3) Remove the thermostatic bypass valve

(A) from the valve housing (fig. 6-223). Press a

6-187

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |