|

|||

|

|

|||

|

Page Title:

Section XXVIII. BRAKE COOLANT PUMP ASSEMBLY-REPAIR |

|

||

| ||||||||||

|

|

TM 9-2520-249-34&P

Table 7-23. Repair Standards (Input Oil Pump)-Continued

Wear limit

Reference

Size and fit

DS/GS

Foldout

Item

Point of measurement

of new parts

maintenance

11

22a

Outside diameter at bearing surface of gear 0.6245 to 0.6250

0.6242

shaft

11

25a

Inside diameter at bearing surface of body 0.8068 to 0.8075

0.8080

11

27a

Outside diameter of bearing .................

To press fit 0.8075

*

to 0.8078 bore

11

25a,

Fit of bearing in body............................

0.0000 to 0.0010T

27a

*Replace when worn beyond new dimensions.

Section XXVIII. BRAKE COOLANT PUMP ASSEMBLY-REPAIR

e. Do not remove needle bearing (57) from

7-164. Description

pump cover (58) unless replacement is necessary.

Refer to paragraph 2-19 for description of the brake

f.

Do not remove two dowel pins (56) from

coolant pump components.

pump cover (58) unless replacement is necessary.

g. Remove two driven gear assemblies (51,

7-165. Disassembly

h. Remove two driven gear shafts (49) and

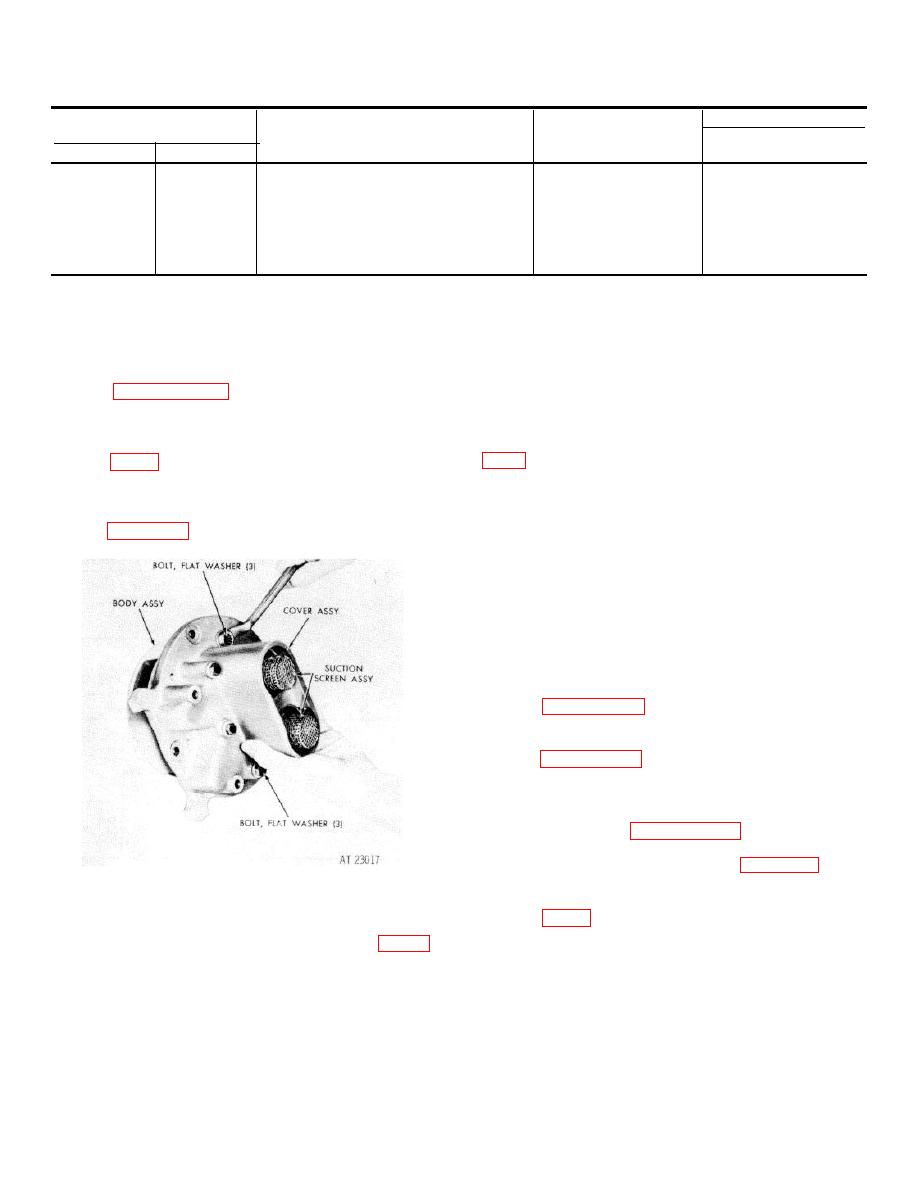

a. Remove three bolts (68), three bolts (70)

two antirotation balls (50) from pump body (46).

and six flat washers (67 and 69). Remove coolant pump

i.

Remove two retaining nuts (41) from

cover assembly (55) from pump body assembly (44).

internal drive gears (48) and remove two external-driven

Refer to figure 7-56.

gears (42).

j.

Remove four thrust washers (43) from

internal drive gears (48).

pump body (46).

l.

Do not remove needle bearing (45 and 47)

unless replacement is necessary.

7-166. Cleaning

Refer to paragraph 5-2 for cleaning recommendations.

7-167. Inspection and Repair

Refer to paragraph 5-3 for general inspection and repair

recommendations.

7-168. Repair Standards

repair standards.

Figure 7-56. Removing (or installing) brake coolant

7-169. Assembly

pump cover assembly bolt.

a. If needle bearing (45) were removed from

pump body (46), press new replacements flush with, to

and two coolant suction screen assemblies (65).

0.005 inch below, the outer surface of the pump body.

c. Remove six washers (60, 62, 64), two

Press against the numbered side of the bearing cage.

check valve guide pins (59), and two springs (61) from

b. If needle bearing (47) was removed from

pump cover (58).

pump body (46), press a new replacement 0.18 inch

d. Do not remove two grommets (63) from

below the surface adjacent to the bearing bore.

washers (62 and 64) unless replacement is necessary.

7-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |