|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-246-34

k. Transfer Top Cover and Shifter Shaft.

i. Case Cover.

NOTE

NOTE

When assembling, use a new gasket and

Use care not to damage or lose taper pins

install new lockwire. Tighten capscrews and

during removal since they are non-supply

lockwashers to 22-28 lb-ft torque.

items and must be fabricated if lost or

damaged.

Remove the four capscrews and lockwashers

securing the top cover to the transfer case. (See fig. 4-

(1) Polish the end of the shifter shaft to remove

33). Remove the top cover and top cover gasket.

roughness and paint. (See fig. 4-31.) Remove the 18

Discard the gasket. Remove the shifter shaft spring,

capscrews, nuts, and lockwashers securing the case

plunger, and ball. (See fig. 4-34.) Using a pair of wire

cover to the case. Remove the three taper pins from

cutters, remove the lockwire from the fork setscrew.

the case and cover, with a drift or punch.

Remove the setscrew, then remove the shifter shaft

NOTE

from the fork assembly.

l. Input Shaft Assembly, Fork Assembly, and Idler

Install taper pins, install new gasket, aline

Shaft Assembly. Using a soft drift pin and hammer,

case cover with taper pins, and tighten nut

drive the input shaft assembly, fork assembly, and

and capscrews evenly and alternately.

idler shaft assembly from the transfer case.

Tighten capscrews marked Y and W to 60-

77 lb-ft torque. Tighten remaining

capscrews marked Z to 67-87 lb-ft torque.

(2) Install puller screws in the two puller-screw

holes located in the flange of the case cover. (See fig.

and tap on the end of the shifter shaft with a mallet.

Lift the cover assembly from the case. Remove and

discard the gasket. Remove the outer thrust washer

from the input shaft.

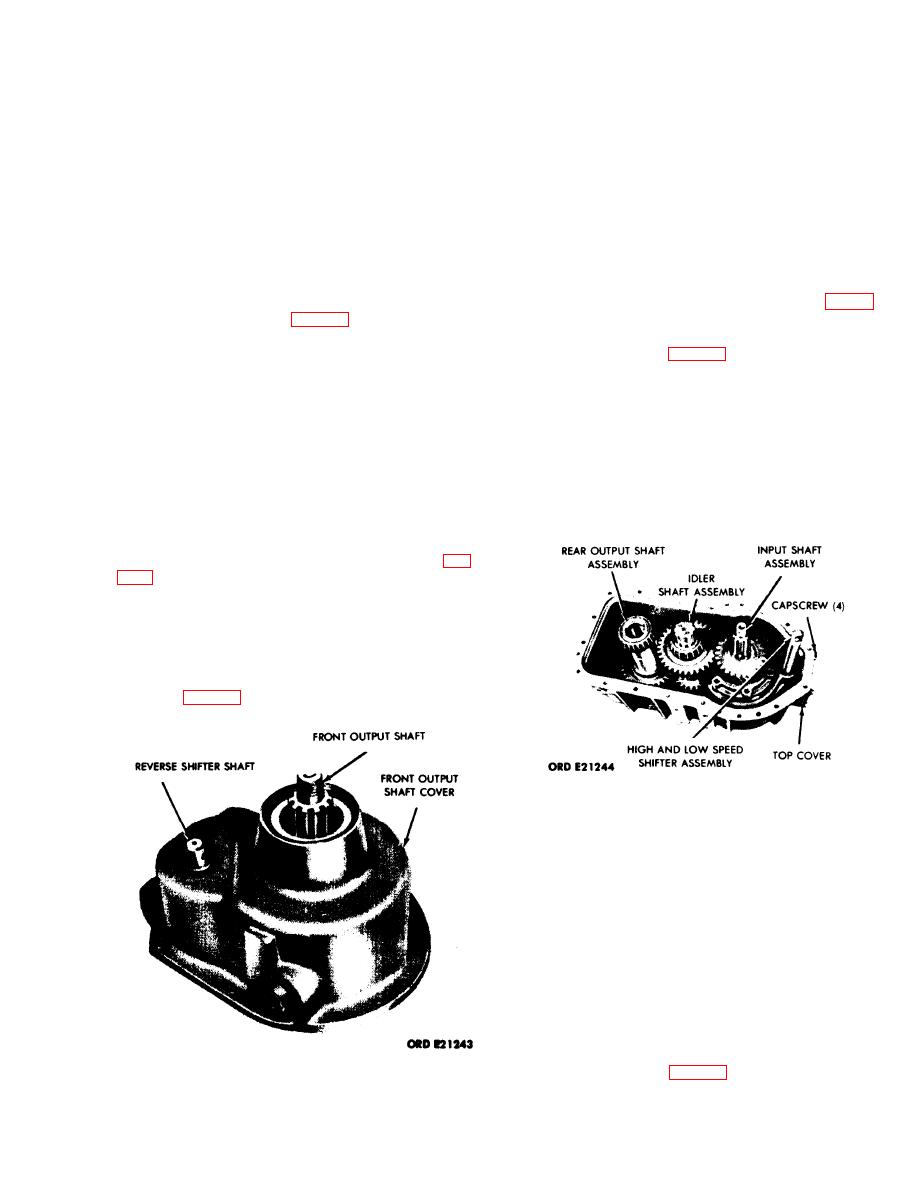

j. Rear Output Shaft Assembly. After the case

cover has been removed, lift the rear output shaft

assembly (fig. 4-33) from the transfer case.

Figure 4-33. Removal of Rear Output, Idler, and

Input Shaft Assemblies

m. Rear Output Shaft Rear Bearing Cover.

NOTE

When assembling, tighten rear output shaft

rear bearing cover capscrews to 60-77 lb-ft

torque. For the installation of shims and

rear bearing adjustments, refer to section

VII of this chapter.

Remove the six capscrews and lockwashers

securing the rear output shaft rear bearing cover to

the transfer case. (See fig. 4-35.) Remove the bearing

Figure 4-32. Removal of Front Output Shaft and

cover and shims from the case. Using a suitable tool,

Reverse Shift Assembly.

remove the oil seal from the rear output shaft cover.

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |