|

|||

|

|

|||

|

Page Title:

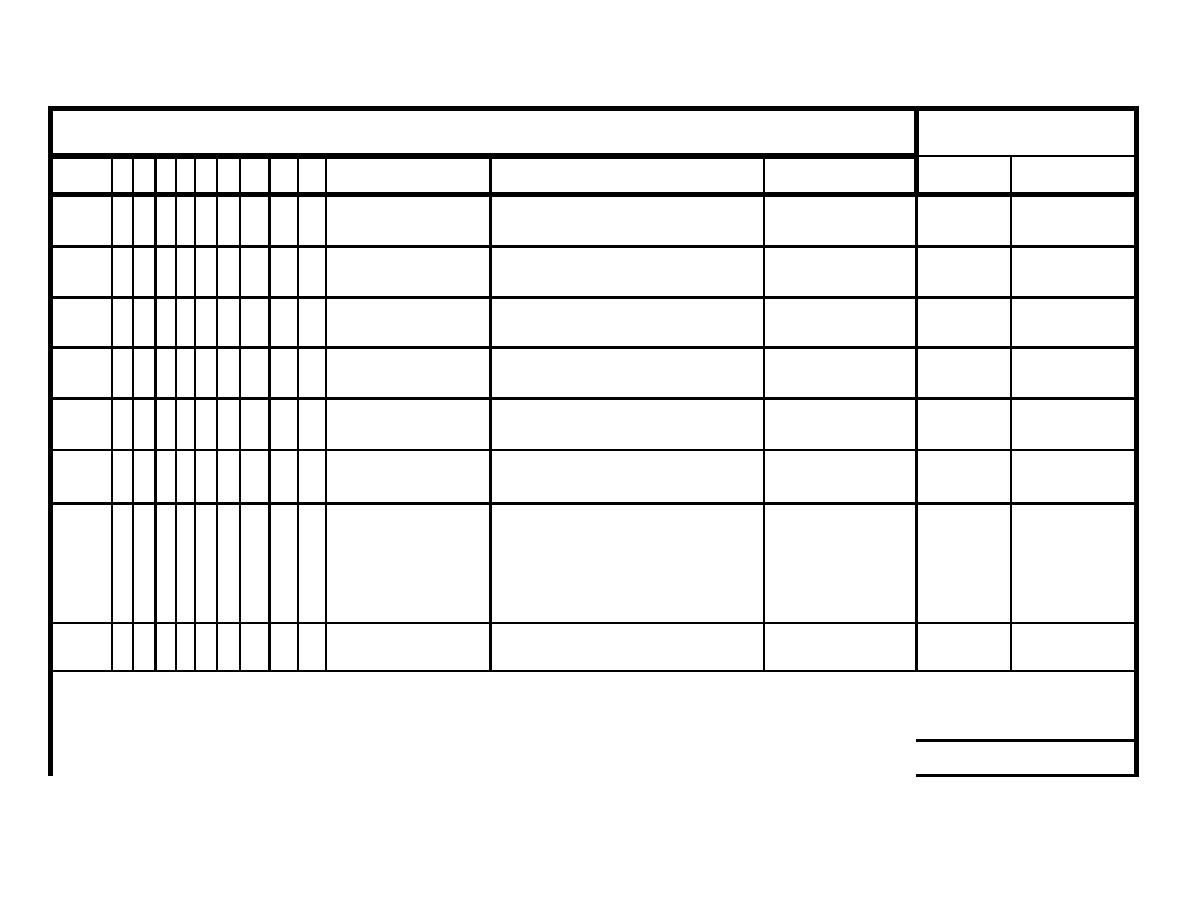

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

Visually inspect pumps for leaks, loose

Repair/replace as

One pump

Both pumps

45

Gear Oil Cooling Pump

connections and damage. Lubricate motor

necessary.

inoperative

inoperative

bearings and impeller shaft bearings.

X

Visually inspect pumps for leaks, loose

Repair/replace as

Pump is inoperative.

46

Lubricating Oil Pump

connections and damage. Lubricate motor

necessary.

bearings and impeller shaft bearings.

X

Visually inspect pumps for leaks, loose

Repair/replace as

Pump is inoperative.

47

Fire/Bilge Pump

connections and damage. Lubricate motor

necessary.

bearings and impeller shaft bearings.

X

Visually inspect pumps for leaks, loose

Repair/replace as

One pump

Both pumps

48

Fuel Oil Transfer Pumps

connections and damage. Lubricate motor

necessary.

inoperative

inoperative

bearings and impeller shaft bearings.

X

Visually inspect pumps for leaks, loose

Repair/replace as

Pump is inoperative.

49

Emergency Fire Pump

connections and damage. Lubricate motor

necessary.

bearings and impeller shaft bearings.

X

Drain worm gear housing oil, clean inside of

Tighten mountings and

50

Lubricating Oil Purifier

housing and re-fill to correct level with clean oil

frame cover as necessary.

(Refer to LO 55-1915-200-12).

X

Check the threads on the lock ring and bowl body. Repair/replace as

Check the bowl spindle radial for wobble. Check necessary.

buffers and ball bearing housing. Replace friction

pads. Check position of coupling disc. Check

bushings for wearing seals, shear pin, and

impeller shaft. Replace brake plug.

Tighten mountings and

X

Drain worm gear housing oil, clean inside of

51

Fuel Oil Purifiers

frame cover as necessary.

housing and refill to correct level with clean oil

(Refer to LO 55-1915-200-12).

LSV PMCS

Change 12

2-272

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |