|

|||

|

|

|||

|

Page Title:

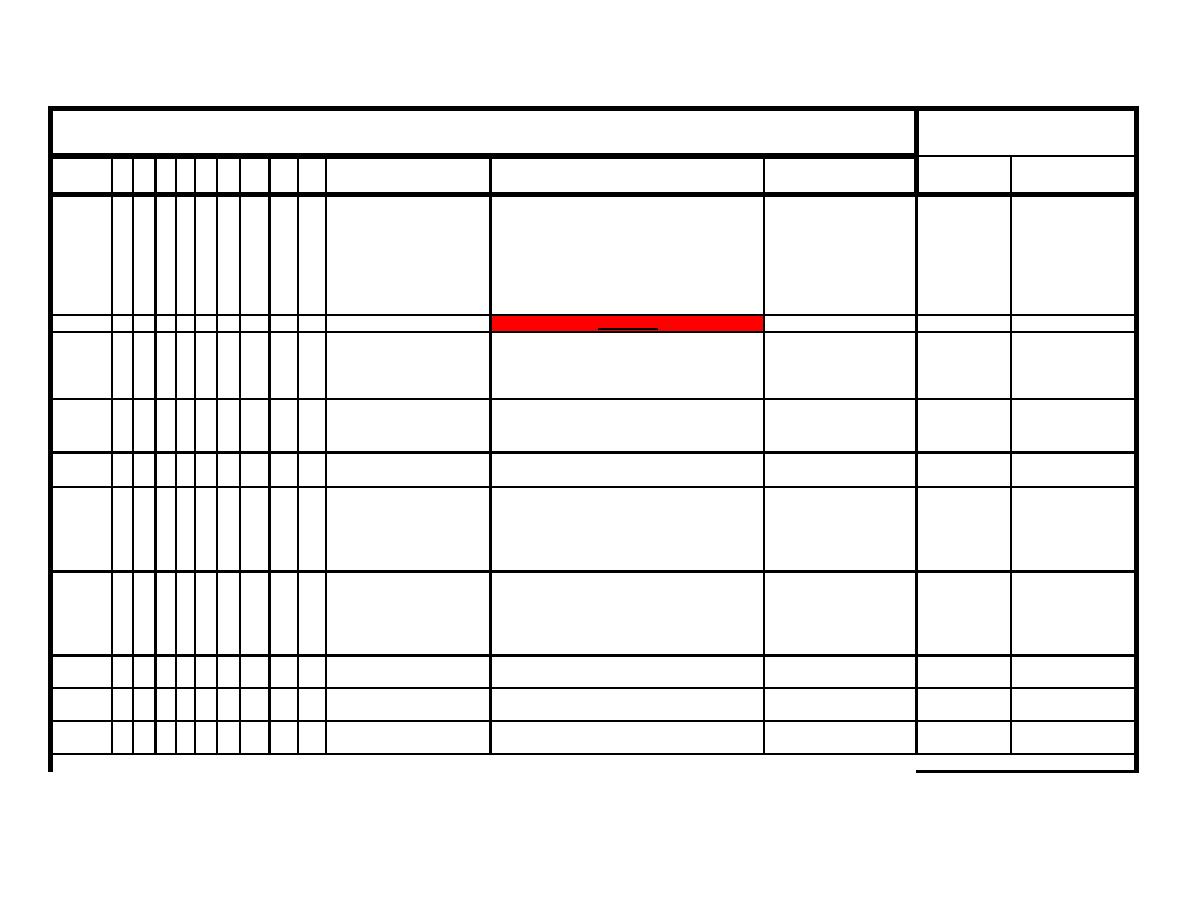

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services (cont) |

|

||

| ||||||||||

|

|

TM 55-1915-200-10

B

Table 2-2. Operator/Crew Preventative Maintenance Checks and Services

EQUIPMENT NOT READY/AVAILABLE

- BEFORE D - DURING A - AFTER W - WEEKLY M - MONTHLY Q - QUARTERLY S/A SEMI ANNUALLY AN - ANNUALLY

IF

T/A - TRIENNIALLY

ITEM

B

D

AWM

Q S/A AN T/A

ITEMS TO BE INSPECTED

CHECK FOR

ACTION

PMC

NMC

NUMBER

X

Check the threads on the lock ring and bowl body. Repair/replace as

Check the bowl spindle radial for wobble. Check necessary.

buffers and ball bearing housing. Replace friction

pads. Check position of coupling disc. Check

bushings for wearing seals, shear pin, and

impeller shaft. Replace brake plug.

WARNING

Prior to any cleaning of the system involving

moving parts, the system should be deactivated

by disconnecting the power supply or injury to

personnel may result.

X

Inspect condenser coils to make certain that air

Remove any debris, clear

52

Ship Stores Refrigeration

flow is not hampered and that they are clear of

airflow restrictions, clean

dust and debris.

coils as necessary.

X

Drain Line

Inspect and check that drain lines are open.

Clear of restrictions as

necessary.

X

Liquid Refrigerant

Check the liquid refrigerant sight glass to make

Troubleshoot, repair as

Absence of

certain that the system is fully charged.

necessary. Recharge

liquid refrigerant.

system.

Restricted

underway time.

X

Condenser and Evaporator

Check both the condenser fan motors and

Troubleshoot,

Excessive noise

Fan Motors

evaporator fan motors to make certain that they

repair/replace as

or vibration.

necessary.

Restricted

are operational and that the fans are tight and

underway time.

secure.

X

Door Gaskets

Check that door gaskets and breaker strips are

Clean, replace/repair as

clean and not damaged/deteriorated.

needed.

X

Check air channels and remote control terminal

Clean as necessary.

53

Arc Welder

strip for dust or dirt buildup.

X

X

Compressed Air Subsystem Check oil level. Maintain level between high and

Add oil as necessary

Low oil level.

54

low marks on bayonet gauge.

LSV PMCS

Change 12

2-273

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |