|

|||

|

|

|||

|

Page Title:

Chapter 2. MAINTENANCE PROCEDURES |

|

||

| ||||||||||

|

|

TM 9-8140-381-14&P

CHAPTER 2

MAINTENANCE PROCEDURES

CAUTION

Unless otherwise specified, remove all items from cage prior to performing maintenance

operations.

Section I. CASTERS

with 3/4-inch socket and socket wrench.

2-1.

REMOVING/INSTALLING

CASTER

g. Lower cage to ground level. Remove pallet jack

or forklift.

a. Lock caster brake on side of cage opposite

caster being replaced. This is accomplished by

rotating caster lock on side of caster clockwise

2-2.

CASTER LUBRICATION

until tight.

a. Lock caster brakes to prevent rolling of cage

b. Use pallet jack (or forklift) to raise cage at least

during lubrication.

9 inches (distance between bottom surface of

NOTE

pallet and floor) off ground.

Some casters are supplied with only

two grease fittings.

c. If pallet jack is used, assure that it is properly

engaged.

b. Using a standard lubricating gun, lubricate each

of the three grease fittings on each caster with

grease.

d. Remove faulty caster using a 3/4-inch socket

and socket wrench. Break loose all four nuts

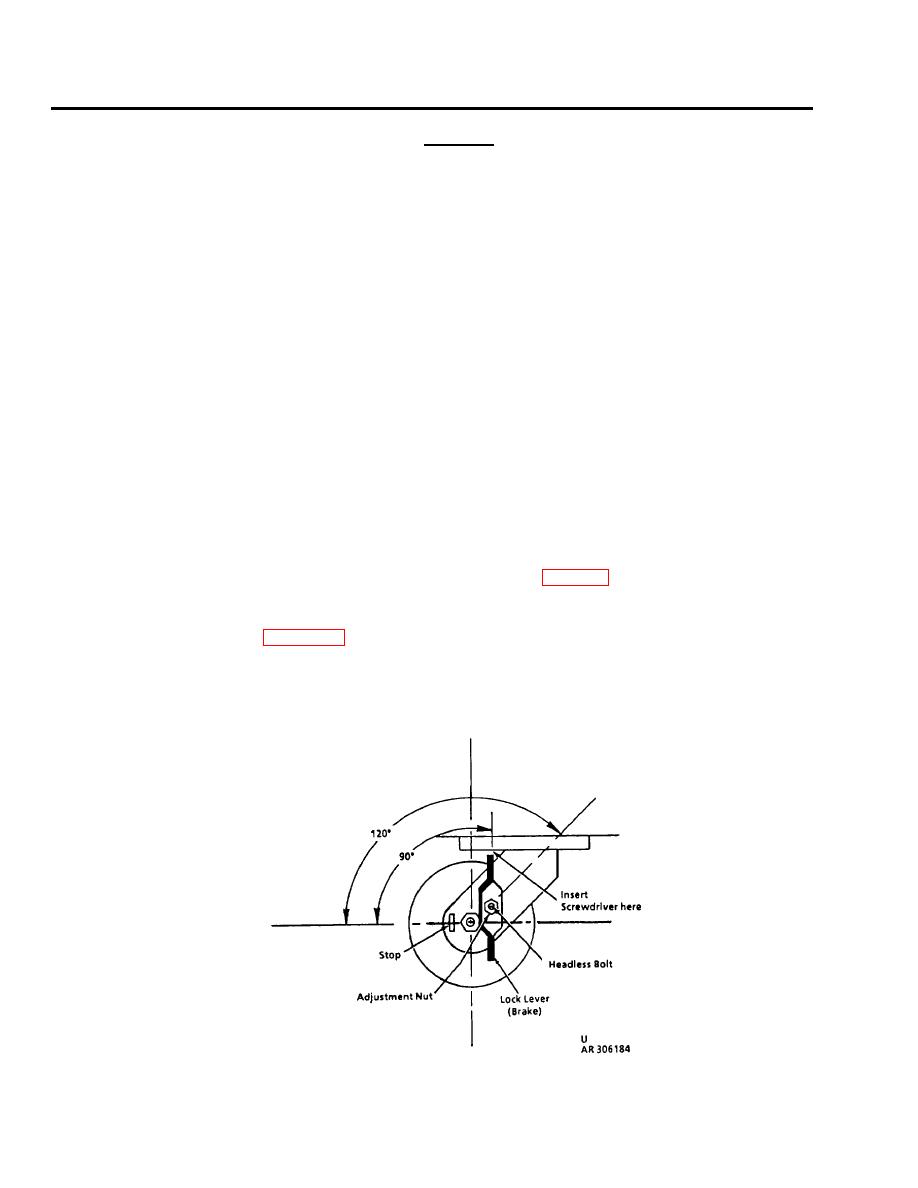

2-3.

CASTER BRAKE ADJUSTMENT

before removing any one nut. Inspect bolt

threads for serviceability.

Replace if

unserviceable.

NOTE

Contents do not have to be removed

for this operation.

e. Check new caster (fig.

swiveling, free rotation, spring-loaded wire ring

2-3.1.

Inspection Procedures.

The following

operation, and brake operation.

procedures are used to check the brake adjustment on

the two front casters.

f. Install new caster (with pull ring to out- side)

Figure 2-1. Caster Lock Lever (Brake) Adjustment

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |