|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-6920-361-13&P

Section IV. TROUBLESHOOTING

are listed in table 3-2. Each malfunction stated is

3-7.

General.

This section provides information

followed by a list of probable causes of the trouble. The

useful in diagnosing and correcting unsatisfactory

corrective action is described opposite the probable

operation or failure of the trainer or subcaliber device

cause.

which is peculiar to operator maintenance operations

only.

Malfunctions

which

may

occur

Table 3-2. Troubleshooting

Malfunction

Probable cause

Corrective action

Failure to fire

Defective firing pin

Replace firing pin.

Weak firing pin compression helical spring

Replace spring.

Defective trigger

Replace trigger.

Failure to extract

Defective extractor

Replace extractor.

Weak or broken extractor spring

Replace spring.

Hard to elevate

Elevating gears out of adjustment

Adjust gears.

Jerky elevation

Burred or stripped gears

Notify direct support

maintenance.

Jerky traverse

Burred or stripped gears

Notify direct support

Tripod legs bind

Bent legs

Notify direct support

maintenance.

Section V. MAINTENANCE INSTRUCTIONS

3-8.

General.

Maintenance by the operator is

confined to replacing the firing pin and firing pin

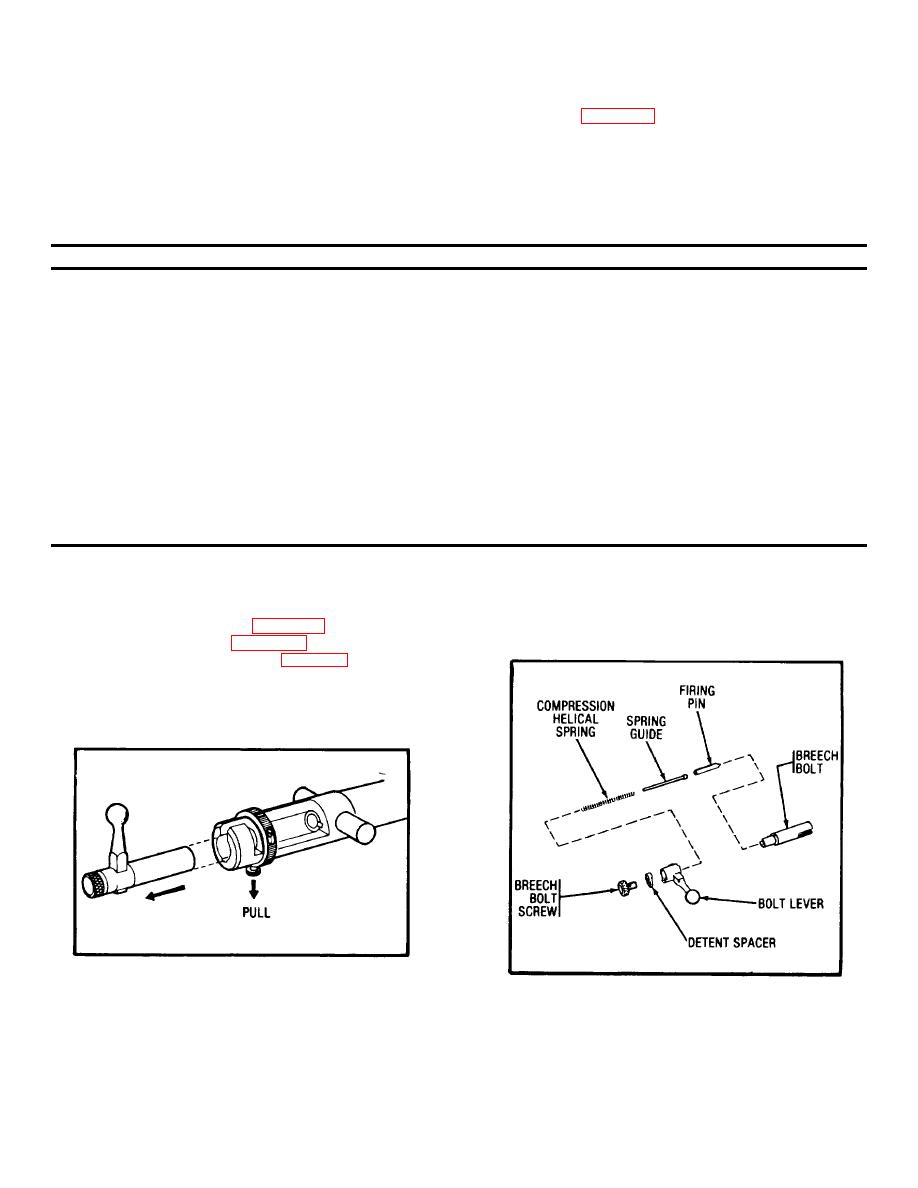

Step 2: Remove the breech bolt screw, detent spacer,

compression helical spring (para. 3-9), cleaning and

and bolt lever. The compression helical spring, spring

lubricating the trainer (para. 3-4), and preventive

guide, and firing pin will now slide out the rear of the bolt.

maintenance checks and services (table 3-1).

3-9.

Maintenance of Firing Pin and Spring. To

replace a damaged or broken firing pin or compression

helical spring, perform the following steps in sequence:

Step 1: Remove the bolt by pulling down on the bolt

locking cap and pulling bolt to the rear.

Step 3: Replace the spring and/or firing pin as required,

then reassemble parts in reverse order.

3-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |