|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2990-206-34&P

INSPECTION--Continued.

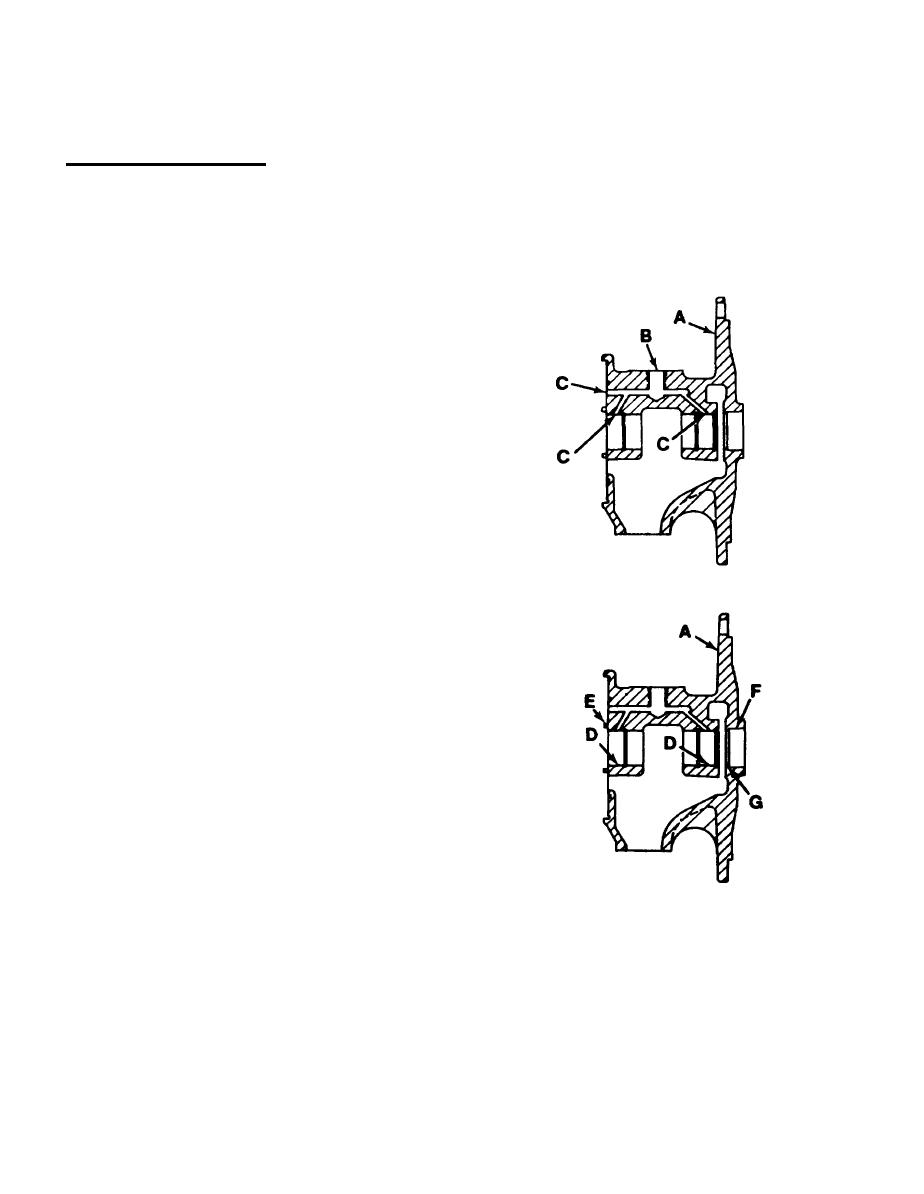

INSPECT CENTER HOUSING

TOOLS:

0.7500 to 1.2500 inch telescope gage

0.00 to 1.00 inch micrometer

1.00 to 2.00 inch micrometer

Inspect center housing (A) for cracks,

1.

nicks, and raised metal. Inspect for

distorted or warped mounting flange and

machined mating surfaces. Inspect tapped

holes for thread damage.

Flush oil holes with solvent, Solvent

2.

must enter through oil inlet hole (B) and

flow freely through three holes (C).

Inspect sleeve bearing bores (D) for

3.

stratches, scoring, or galling.

Inspect for bent, cracked, or loose

4.

Pins must be secure

locating pins (E).

and not damaged.

Measure sleeve bearing bore diameters (D)

5.

using telescope gage and micrometer. Re-

place center housing if bore diameter

exceeds 0.9832 inch (24.97 mu).

6.

Measure seal ring bore diameter (F)

using telescope gage and micrometer.

Replace center housing if bore diameter

exceeds 1.0310 inch (26.19 inn).

Measure step bore (G) using telescope

7.

gage and micrometer. Replace center

housing if bore diameter exceeds 1.0210

inch (25.93 mm).

Replace center housing if damaged, or

8.

does not meet wear limit requirements.

TA097821

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |