|

|||

|

|

|||

|

Page Title:

Installation of Flinger Sleeve Insert, Retaining Ring, Compressor Wheel Shims, and Compressor Wheel. |

|

||

| ||||||||||

|

|

TM 9- 2990- 205- 34&P

-

-

-

ASSEMBLY AND OPERATIONAL TESTING - CONTINUED

-

0012 00

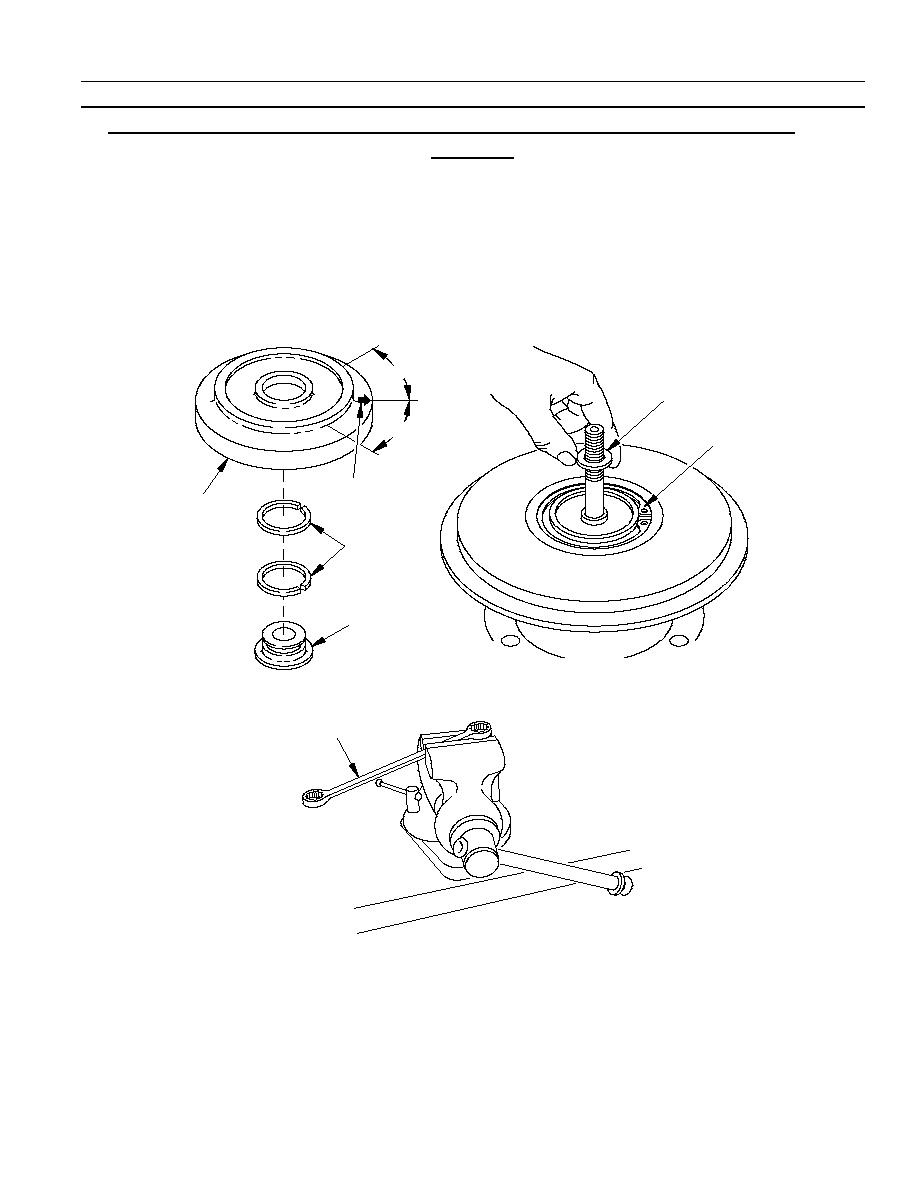

6. Installation of Flinger Sleeve Insert, Retaining Ring, Compressor Wheel Shims, and Compressor Wheel.

CAUTION

Use steady pressure but do not force flinger sleeve insert into bearing housing; metal seal

rings or flinger sleeve may fracture.

a. Center metal seal rings (1) on flinger sleeve (2) with gaps in rings 90 degrees apart.

b. Install flinger sleeve insert (3) in bearing housing below retaining ring groove. The arrow (4) stamped on the

top of the insert should be in line with the oil inlet port of the bearing housing.

c.

Install retaining ring (5).

d. Install compressor wheel shims (6).

45 o

6

45 o

5

4

3

1

2

03i493m

e. Place a 1--1/8 inch angular 12 point box wrench (7) in a vise. Position wrench to hold turbine wheel hub.

7

03i494m

0012 00- 7

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |