|

|||

|

|

|||

|

Page Title:

Figure 35. Undercutting mica using alternate hand method. |

|

||

| ||||||||||

|

|

the final cut should not be

Minor

Positork Drive Assembly.

c.

more than 0.002-inch.

After

damage such as nicks, burs, etc, of the

armature

resurfacing,

check

positork drive maybe repaired with a file

against limits specified in re-

providing it does not destroy the effec-

pair and rebuild standards (par.

tiveness of the snap ring groove.

40) and replace it if it falls

below these limits.

d.

Bearing

Retainer.

Intermediate

Minor damage such as nicks, burs, etc, of

the intermediate bearing retainer may be

repaired with a fine mill file.

g.

Armature.

(1)

Resurfacing. Sharpen the lathe

cutting tool to the dimensions

given in figure 32.

Note.

For commutator turn-

ing, the lathe cutting tool must

be extremely sharp. After grind-

ing, hone the tool with a fine

hard stone to insure a smooth

cut during the turning opera-

tion.

Position the tool with respect

to the commutator as shown in

figure 33.

Resurface the com-

mutator at 800 rpm taking only

light cuts each time. No more

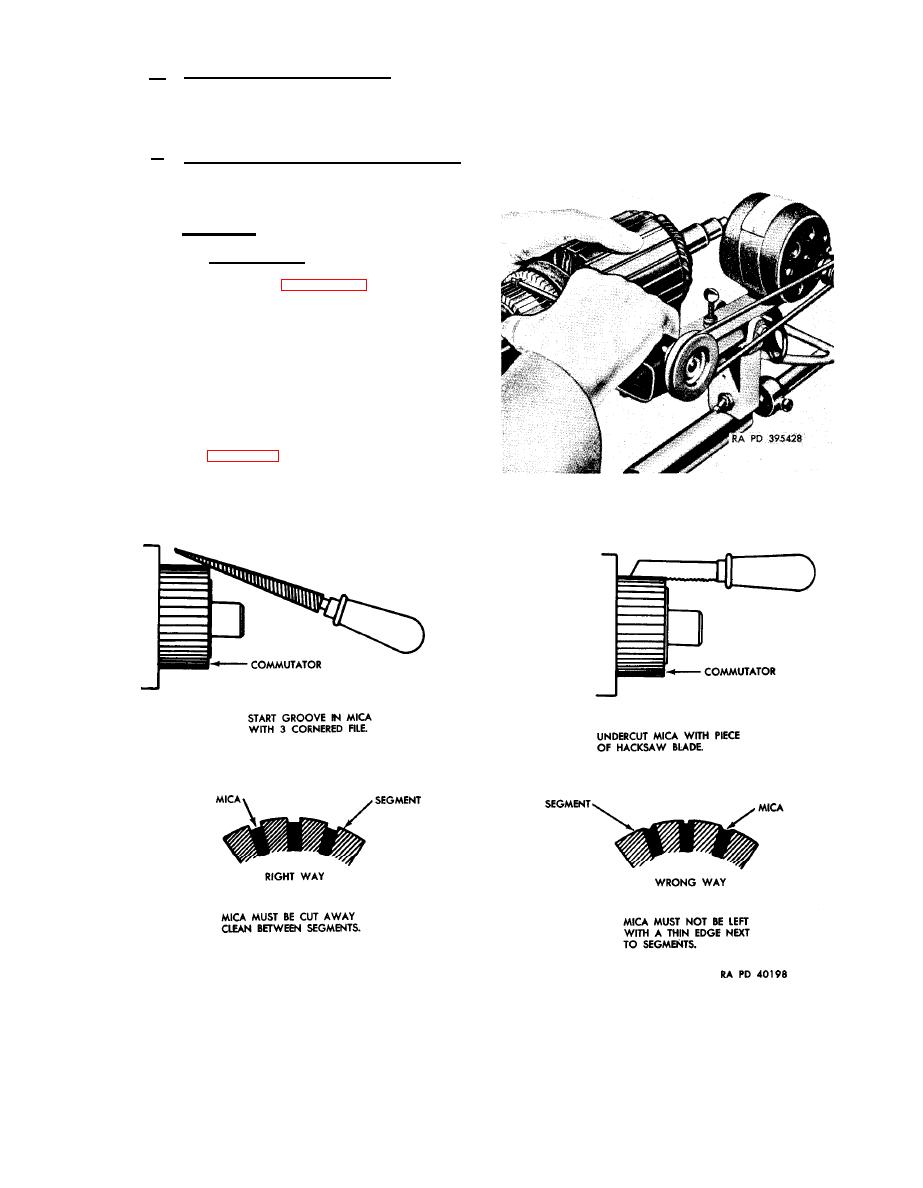

34. Undercutting mica

using

than 0.005-inch should be re-

a power-driven tool.

moved during any one cut and

Undercutting mica using alternate hand method.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |