|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9- 2920- 232- 34&P / TO 38X14- 2- 32

-

-

-

- -

TROUBLESHOOTING INSTRUCTIONS - CONTINUED

-

0005 00

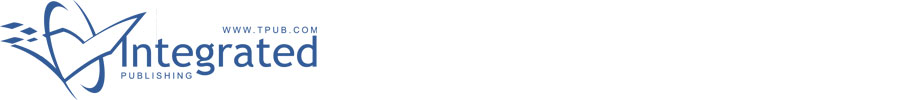

10) Clutch Override. A clockwise (viewed from drive end) torque applied quickly to the drive pinion by thumb

pressure when armature is at rest (fig. 2--9) will check overrunning clutch. Drive pinion should rotate

without rotating armature.

11) Brush Arcing. When armature speed and starter current are both less than minimums indicated in

preceding step (3), check for excessive arcing of brushes (Table 2--1; Malfunction No. 8) during a no--load

run.

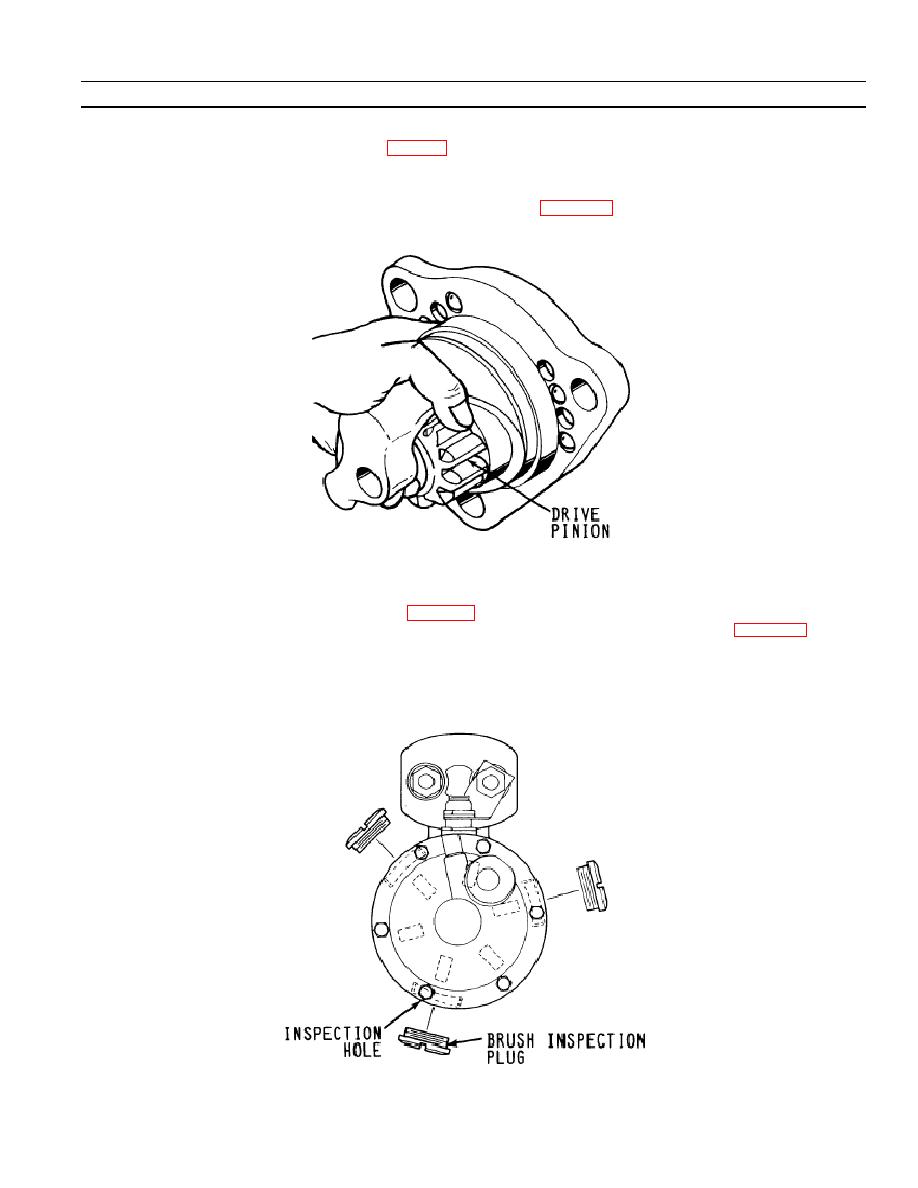

12) Remove three brush inspection plugs (fig. 2--10) and look into motor through each opening. Any unusual

arcing seen at brush contact surface can be due to one or more of the causes listed in Table 2--1.

13) If arcing is localized to an area near a particular inspection hole, check for worn, binding, or broken

brushes and/or a defective brush spring.

14) Commutator problems should produce arcing in all three areas seen through inspection holes.

0005 00- 5

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |