|

|||

|

|

|||

|

Page Title:

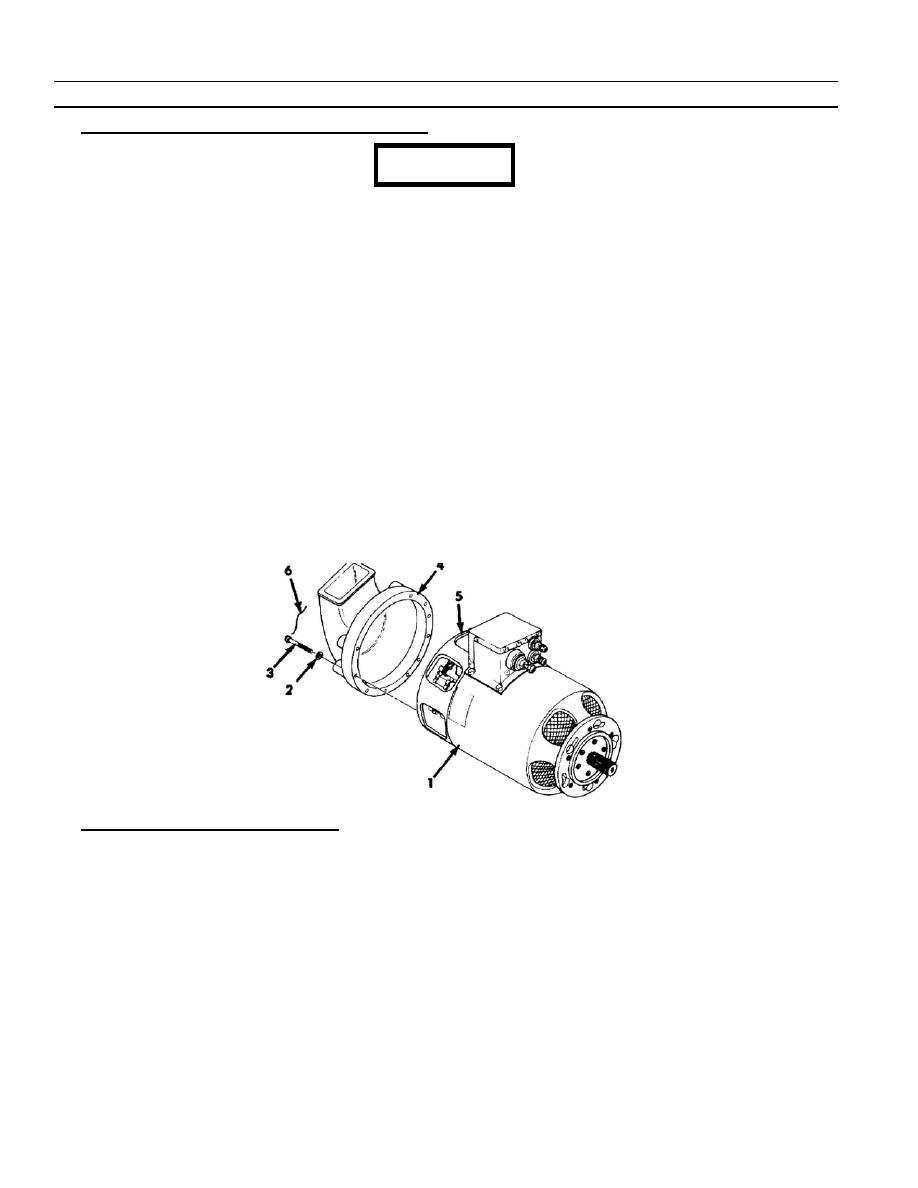

Air Intake Generator Housing Generator (11642898). |

|

||

| ||||||||||

|

|

TM 9- 2920- 224- 34&P

-

-

-

ASSEMBLY OF THE GENERATOR - CONTINUED

-

0010 00

12. Air Intake Generator Housing Generator (11642898).

CAUTION

Avoid getting sealant in or over mounting holes in air

intake generator housing.

a. On generator (11642898), apply a 1/16 inch thick coat of sealant to mounting surface of air intake generator

housing (1). Perform step b before sealant sets.

NOTE

Reference marks made during disassembly will be aligned when housing is properly posi-

D

tioned on support assembly.

Bring mounting surfaces together while sealant is still wet.

D

b. Install flat washer (2) on each of ten machine screws (3), and put screws through mounting holes in housing

(1). Position housing aligned with support assembly (4) and close enough for all screws (3) to be started in

tapped holes of stator housing (5).

c.

Torque machine screws (3) to 37--42 Ib--in (4.2 to 4.7 NSm) alternately and evenly.

d. Wipe excess sealant from around housing (1) and support assembly (4) junction.

e. Use five 12--inch pieces of nonelectrical wire (6) to tie screws (3) in pairs.

4

13. Generator Band Assembly and Gasket.

a. The generator band assembly and band assembly gasket must be installed to complete assembly of

generator, but these components must be off generator for run--in and operational testing.

b. Installation procedures for these parts are included in operational test procedure at location where installation

should occur.

END OF TASK

0010 00- 22

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |