|

|||

|

|

|||

|

Page Title:

Figure 3-102. Inspection of spill ports and plunger sleeve. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

(2) Manually work plunger up and down,

rotating slowly to make sure plunger is free in bore

There cannot be any binding.

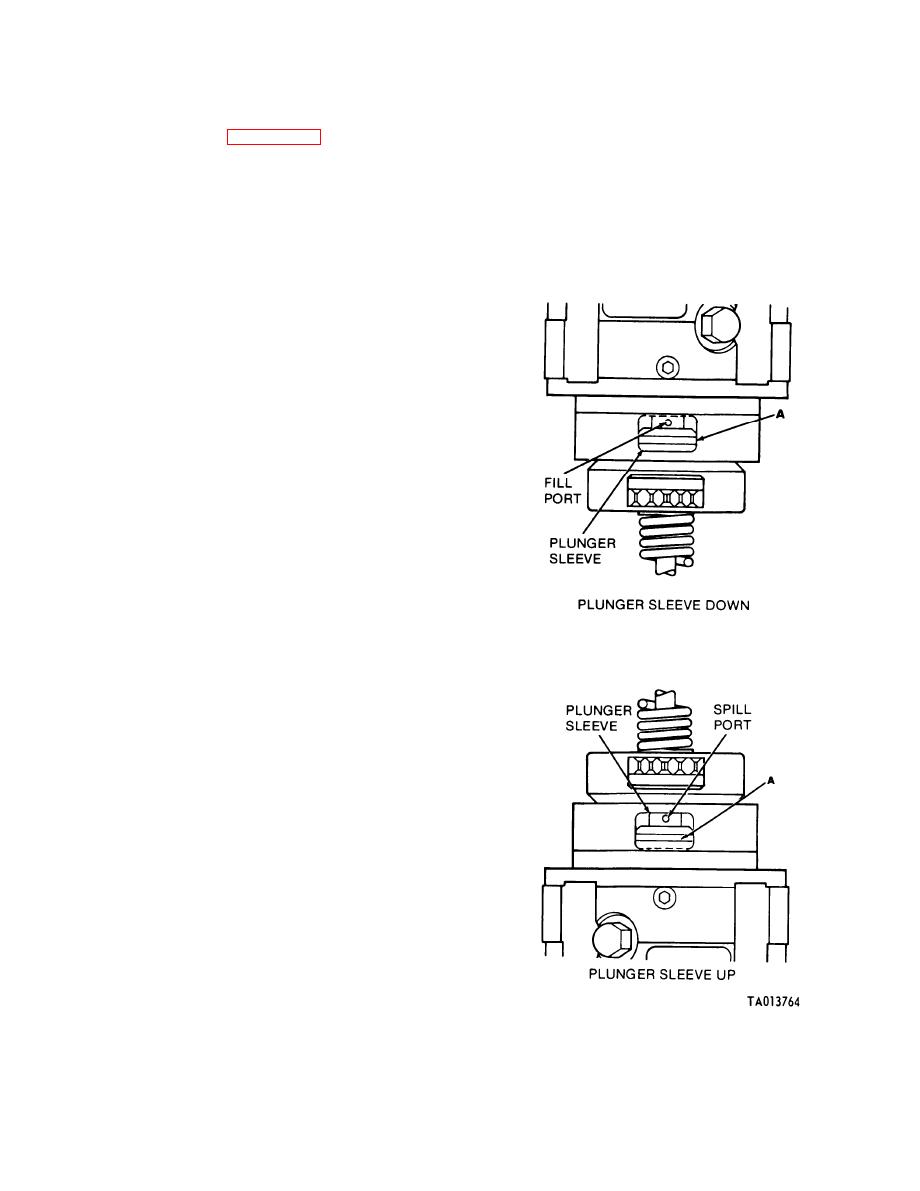

(3) Refer to figure 3-102. Using suitable feeler

gages check plunger sleeve slot width (A). Replace

head if slot width is greater than 0.1007 in. Sleeve

should fall of its own weight on plunger. If it does

not, lubricate with diesel fuel and recheck. If sleeve

does not free up, discard head assembly.

Figure 3-102. Inspection of spill ports and plunger sleeve.

3-63

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |