|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

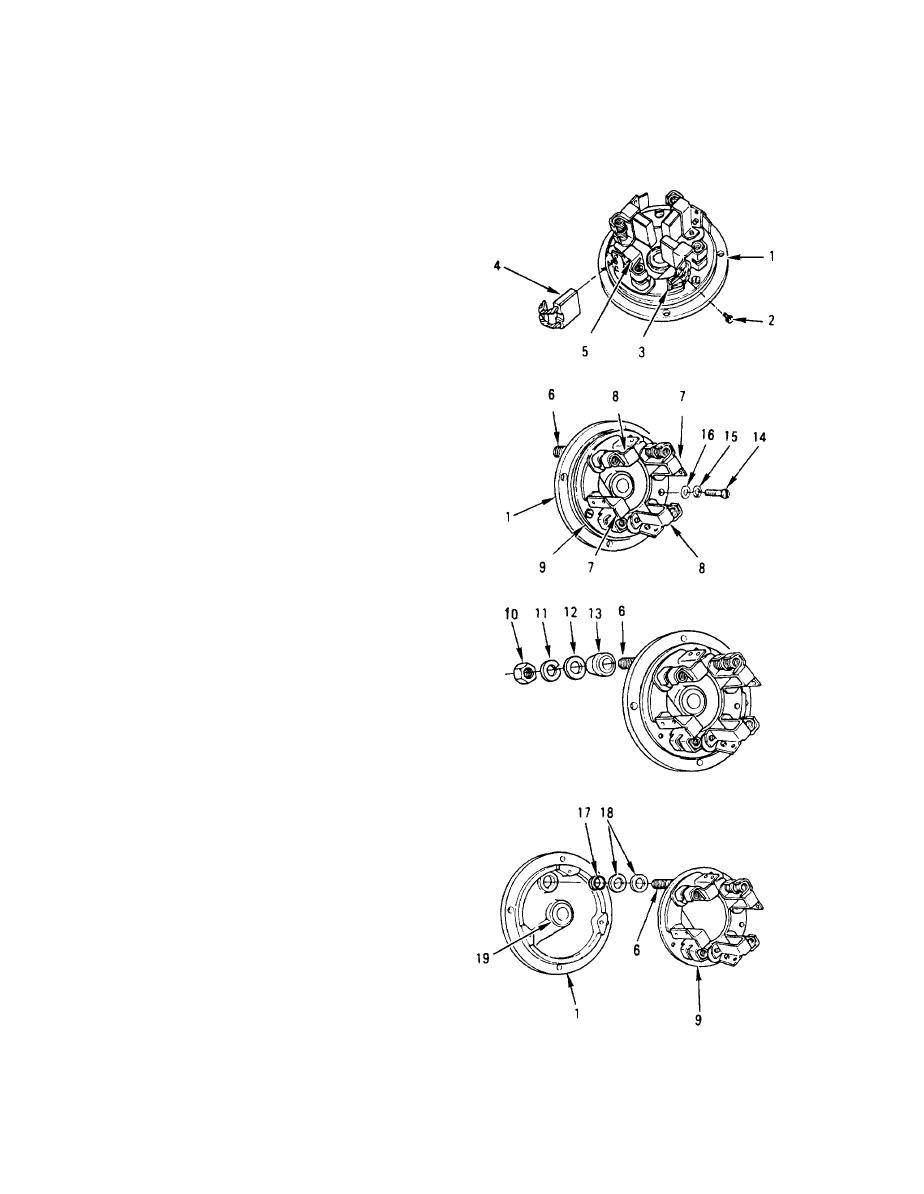

TM 9-2835-255-34

STARTER MOTOR REPAIR (Sheet 9 of 12)

20, PUT END BELL (1) IN VISE. REMOVE

FOUR SCREWS (2) FROM BRUSH LEADS

[3). PULL FOUR BRUSHES (4) OUT OF

BRUSH HOLDERS (5).

21. SET MULTIMETER TO RX1000 SCALE

AND CHECK CONTINUITY BETWEEN

TERMINAL STUD (6) AND TWO

INSULATED BRUSH HOLDERS (7). IF

MULTIMETER READS LESS THAN

INFINITY FOR EITHER CHECK, SKIP

STEP 22.

22. SET MULTIMETER TO RX1 SCALE.

CHECK CONTINUITY BETWEEN STUD (6)

AND TWO GROUND BRUSH HOLDERS (8).

IF MULTIMETER READS 10 OHMS OR

LESS, GO TO STEP 28.

23. SEPARATE HOLDER ASSEMBLY (9) AND

END BELL (1).

a. Remove nut (10), lockwasher (11), washer

(12), and insulator (13) from stud (6).

b. Remove three screws (14), lockwashers

(15), and washers (16) from holder (9).

Tap stud (6) until holder (9) separates

from end bell (1).

24. PULL PREFORMED PACKING (17) AND

TWO WASHERS (18) FROM STUD (6).

REMOVE HOLDER (9).

25. INSPECT END BELL (1) FOR CRACKS OR

BREAKS. INSPECT BUSHING (19) FOR

CRACKS, BREAKS, OR SCORE MARKS.

REPLACE AS REQUIRED.

26. INSTALL TWO NEW WASHERS (18) AND

NEW PACKING (17) ON HOLDER (9) AND

END BELL (1)

a. Put washers (18) and packing (17) on stud

(6) of holder (9).

b, Apply sealing compound to back of holder

(9).

c. Aline holder (9) with end bell (1). Install

three screws (14), new lockwashers (15),

and washers (16).

27. INSTALL NUT (10), NEW LOCKWASHER

(11), WASHER (12), AND NEW

INSULATOR (13) ON STUD (6).

Go on to Sheet 10

9-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |