|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2835-255-34

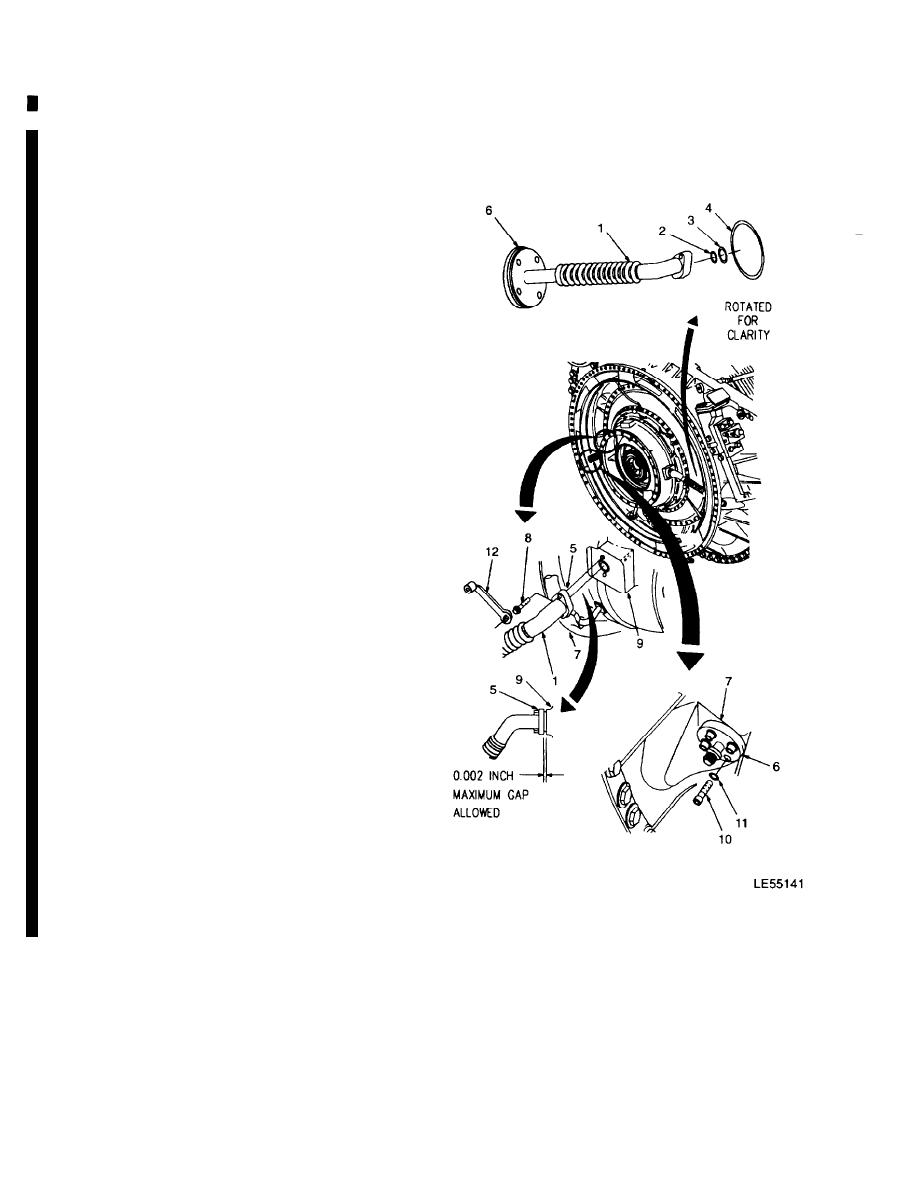

GAS TURBINE POWER UNIT REPLACEMENT (Sheet 29 of 30)

36. INSTALL OIL FEED TUBE ASSEMBLY (1), GAS-

KET (2) METAL SEAL RING (3) AND PACKING MA-

TERIAL (4).

a.

Apply Ultrachem assembly fluid to gasket (2)

and metal seal ring (3). Install gasket (2) and

seal ring (3) on tube inner flange (5).

b.

Install packing material (4) on tube outer

flange (6). Use Ultrachem assembly fluid to

hold packing material (6) in place.

Insert oil feed tube assembly (1) through re-

C.

generator (7).

d. Apply antiseize compound to two bolts (8) and

secure tube inner flange (5) to gas turbine

power unit housing (9). Do not torque bolts

(8).

e.

Apply antiseize compound to four bolts (10).

Loosely install bolts (10) and washers (11) into

tube outer flange (6) and regenerator (7).

NOTE

Torque two inner bolts (8) first, then torque

four outer bolts (10).

37. USING TORQUE ADAPTER (12), TIGHTEN

BOLTS (8) BETWEEN 49-57 LB-IN (5.5-6.5 NM)

TORQUE. WAIT TEN MINUTES AND RETORQUE.

TIGHTEN BOLTS (10) BETWEEN 80-100 LB-IN

(9-11 NM) TORQUE.

38. USE FEELER GAGE AND CHECK GAP BE-

TWEEN FLANGE (5) AND GAS TURBINE POWER

UNIT HOUSING (9). THE GAP SHALL BE NO LARG-

ER THAN 0.002 INCH (0.051 MM). IF GAP IS GREAT-

ER THAN 0.002 INCH, REPLACE OIL SCAVENGE

TUBE ASSEMBLY (1).

39. SAFETY WIRE BOLTS (8) USING TWO WIRE

TWIST METHOD AND BOLTS (10) USING SINGLE

WIRE METHOD.

Go on to Sheet 30

6-90

Change 6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |