|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2835-255-34

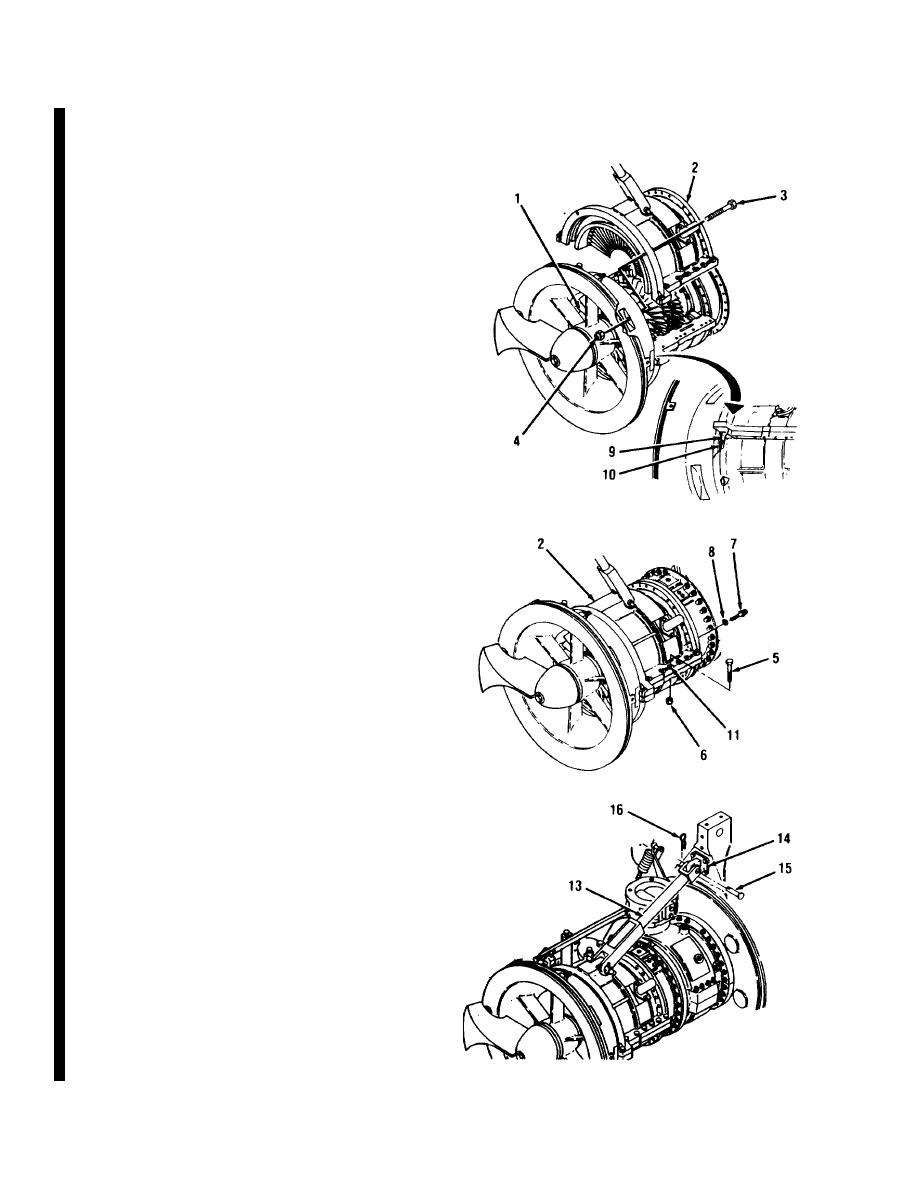

LOW PRESSURE ROTOR AND HOUSING ASSEMBLY (COMPRESSOR) AND HIGH PRESSURE

AXIAL COMPRESSOR AND ROTOR CLEANING (Sheet 9 of 21)

15. MOVE INLET GUIDE VANES (1) ALL THE

WAY CLOSED, AND INSTALL LOW

PRESSURE VANE AND STATOR ASSEM-

BLY (TOP HALF) (2). INSTALL TWO CAP

SCREWS (3), NEW NUTS (4), FOUR BOLTS

(5), AND NUTS (6), FOURTEEN BOLTS (7)

AND NEW WASHERS (8). TIGHTEN

BOLTS (5) AND NUTS (6). TORQUE

BOLTS (7) BETWEEN 68-75 LB-IN (7-9

Nm).

a. Move inlet guide vanes (1) by hand all the

way to the closed position.

b. Position vane and stator assembly (top

half) (2) on engine. Do not damage or

move packing (9) out of groove (10).

c. Install two cap screws (3) and new nuts (4).

d. Install two bolts (5) and nuts (6) on both

sides of case and stator assembly (2), in

two holes (11 ) of split line flange (12).

Tighten bolts (5) and nuts (6).

Apply antiseize compound to 15 bolts (7).

e.

Install 14 bolts (7) and new washers (8).

Torque bolts (7) between 68-75 lb-in (7-9

Nm.

m

16. ATTACH CONNECTING LINK (13) TO

BRACKET (14). INSTALL PIN (15) AND

LOCKPIN (16).

Go on to Sheet 10

5-42 Change 4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |