|

|||

|

|

|||

|

Page Title:

AGB GEAR TRAIN TURNS UNEVENLY (BINDS) WHEN TURNED BY HAND, LOW PRESSURE COMPRESSOR RUBS OR BINDS WHEN TURNED BY HAND AND THER... |

|

||

| ||||||||||

|

|

TM 9-2835-255-34

3 - 2 . TROUBLESHOOTING - CONTINUED

I

I

a. ACCESSORY GEARBOX (AGB) AND

(8) ES-8. AGB GEAR TRAIN TURNS

HIGH PRESSURE COMPRESSOR -

UNEVENLY (BINDS) WHEN TURNED BY

CONTINUED

HAND, LOW PRESSURE COMPRESSOR

RUBS OR BINDS WHEN TURNED BY

HAND AND THERE ARE METAL CHIPS

I N THE OIL PUMP TO OIL COOLER

FLUID FILTER.

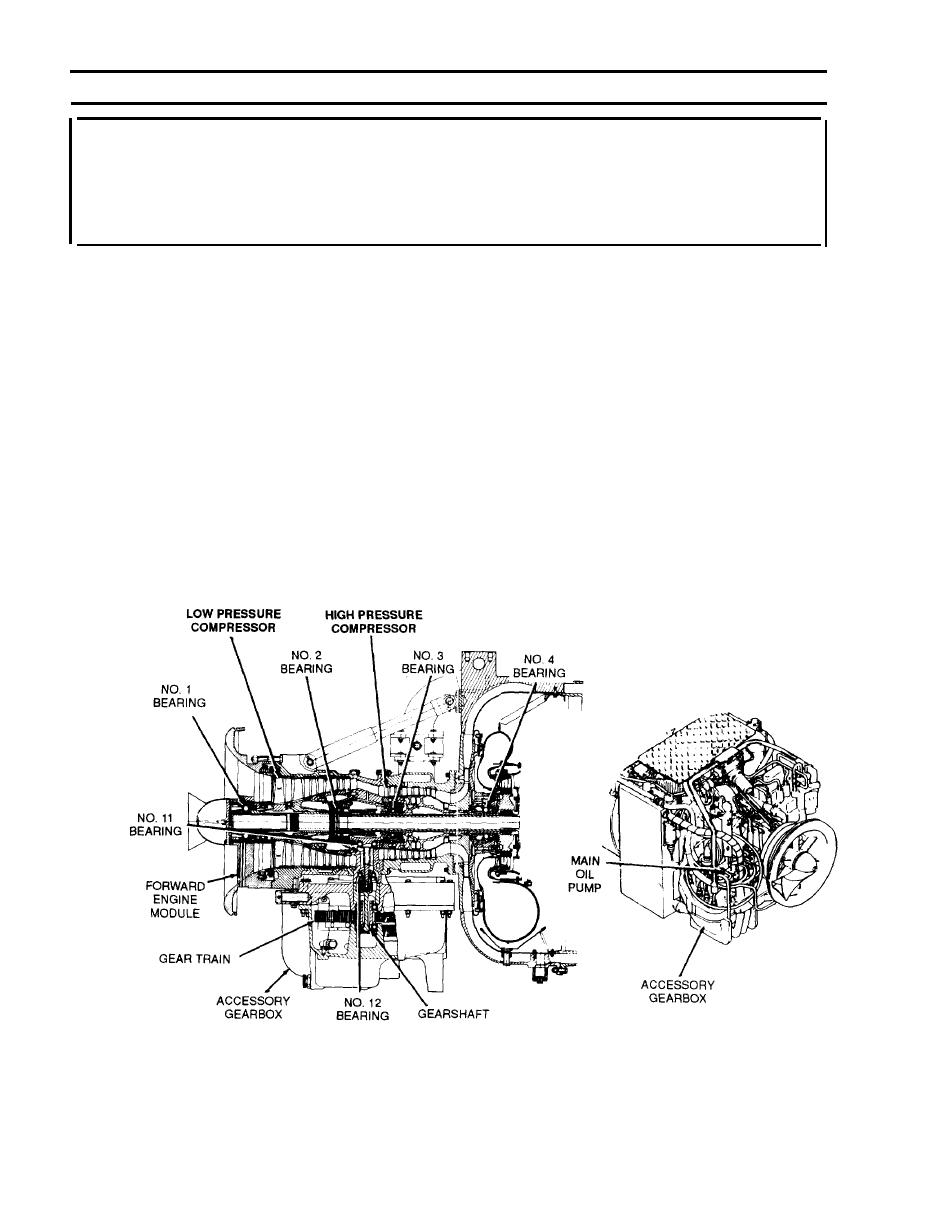

This section contains troubleshooting to locate and correct the cause(s)

of binding in the AGB gear train when turned by hand, rubbinq or binding

in the low pressure compressor when turned by hand, and metal chips in

t h e o i l p u m p t o o i l c o o l e r f l u i d f i l t e r . The AGB is coupled to the high

pressure compressor in the forward engine module through a gearshaft. If

there is damage to the high pressure compressor, forward engine module

position No. 3, 4, 11 or 12 bearing, or AGB gears and/or bearings,

binding will be felt when the AGB gear train is turned by hand. The low

pressure compressor is mechanically coupled to the low pressure turbine

rotor in the rear engine subassembly. If there is damage to the low

pressure compressor or position No. 1 or 2 bearing in the forward engine

module, o r t o t h e l o w p r e s s u r e t u r b i n e r o t o r o r p o s i t i o n N o . 5 b e a r i n g

in the rear engine subassembly, binding will be felt when the low

pressure compressor is rotated by hand. The lubrication system delivers

h o t o i l , scavenged from bearing packages throughout the engine, through

a fluid filter, to the engine oil cooler. The cooled oil is then

returned to the oil tank. Whenever metal chips are generated, the fluid

filter will catch and retain most of the chips. The art on the following

pages provides an overview of the systems described above. Refer to

these pages along with in-text art while performing troubleshooting.

3-56

Change 5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |