|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Engine Governor Maintenance Instructions (Cont)

b . Cleaning/lnspection.

WARNING

. Adhesives, solvents, and sealing compounds can burn easily, can give off

harmful vapors, and are harmful to skin and clothing. To avoid injury or death,

keep away from open fire and use in well-ventilated area. If adhesive, solvent,

or sealing compound gets on skin or clothing, wash immediately with soap and

water.

l Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa).

Use only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc.).

(1)

Scrape old sealant from parts.

Clean all metal parts with dry cleaning solvent.

(2)

(3')

Dry metal parts, except bearings, with compressed air. Let bearings air dry.

(4)

Inspect housing for cracks, warpage and damages threads.

(5)

Inspect bearings for pitting, corrosion, or rough spots.

(6)

Inspect mechanical parts for nicks and burrs.

(7')

Replace all damaged parts.

Assembly.

c

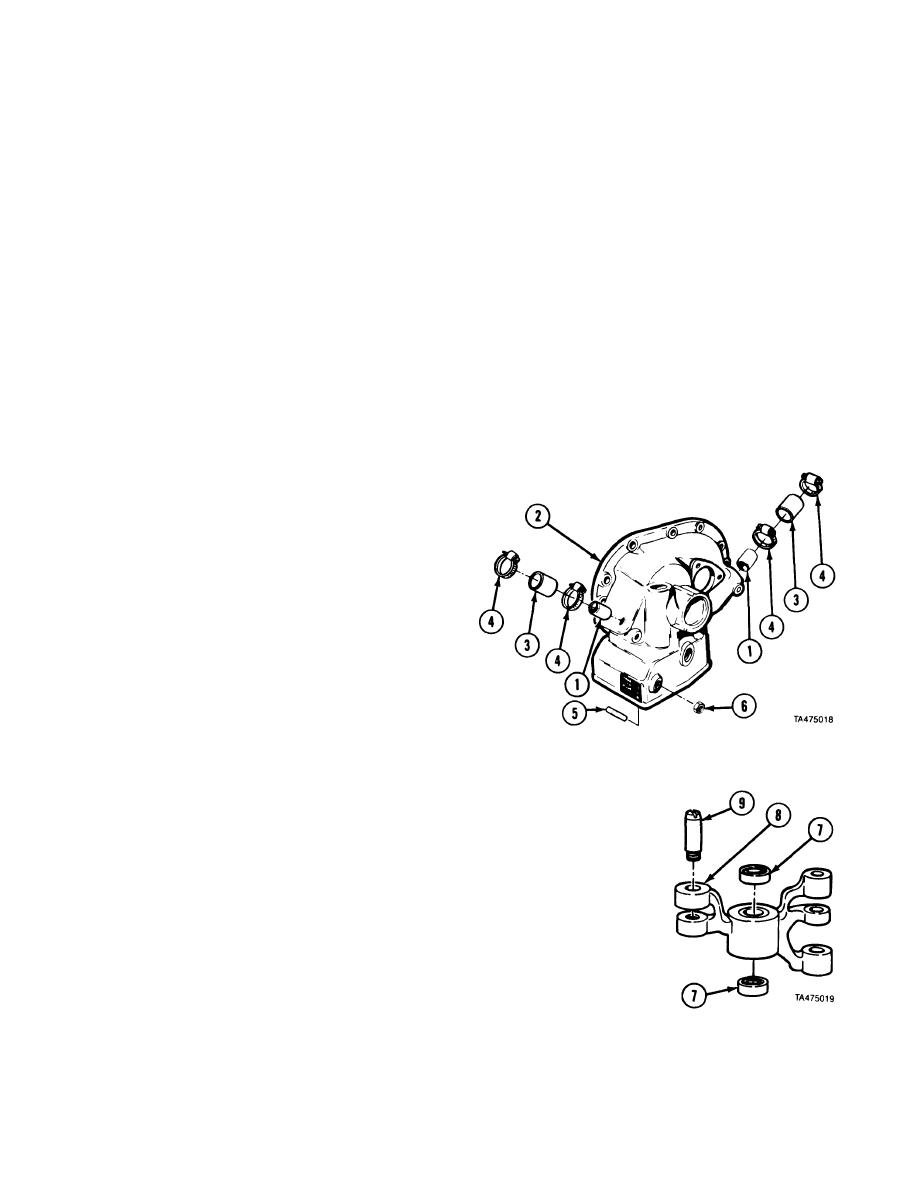

(1) Press twO tubes (1) into governor

housing (2).

(2) Install two hoses (3) with four

clamps (4).

NOTE

--

Screw must be installed from inside

housing.

(3) Install screw (5) and locknut (6).

NOTE

Press bearings flush with operating lever,

(4) Lubricate two bearings (7) with grease. Press bearings, numbered

side up, into control link operating lever (8).

(5) Install pin (9).

15-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |