|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Blower Maintenance Instructions (Cont)

BLOWER REPAIR.

This task covers:

c. Assembly

a. Disassembly

d. Follow-on Maintenance

b. Cleaning/Inspection

INITIAL SETUP

Personnel Required

Models

MOS 63W, Wheel vehicle repairer

All

Test Equipment

References

None

None

Equipment Condition

Special Tools

Condition Description

Tool set, blower service J6270-F

TM or Para

Governor housing

Gage set, piston J3174-02

assembly removed.

Seal installer J35787-2

Spacer installer J35787-1

Blower on clean work

surface.

Supplies

Adhesive-sealant, silicone, Item 6, Appendix C

Special Environmental Conditions

None

Cloth, crocus, Item 17, Appendix C

Oil, lubricating, Item 48, Appendix C

General Safety Instructions

Sealant, Teflon, Item 57.1, Appendix C

None

Solvent, drycleaning, Item 60, Appendix C

Tags, identification, Item 61, Appendix C

Level of Maintenance

General Support

a.

Disassembly.

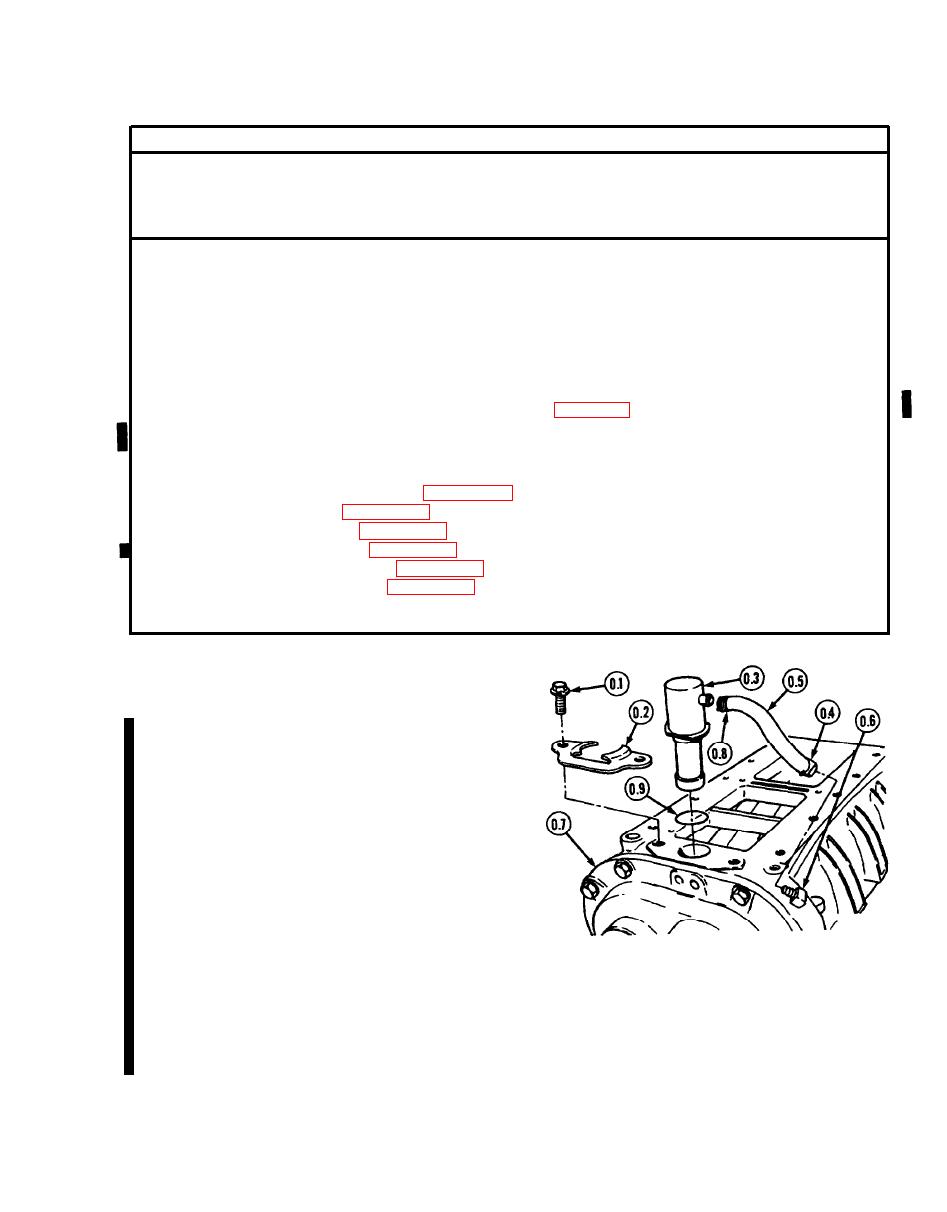

NOTE

Some engines are equipped with a bypass valve on

the blower. If equipped with bypass valve, do

steps (1) through (1.7). If not, go to step (1.8).

Remove two screws (0.1) from pressure

(1)

clamp (0.2).

(1.1) Remove pressure clamp (0.2) from bypass

valve (0.3).

(1.2) Compress clamp (0.4) and pull hose (0.5)

off of hose fitting (0.6).

(1.3) Remove bypass valve (0.3) with hose (0.5)

from blower (0.7).

(1.4) Remove two clamps (0.4 and 0.8) from

hose (0.5).

(1.5) Remove hose (0.5) from bypass valve (0.3).

(1.6) Remove and discard preformed

packing (0.9) from bypass valve (0.3).

(1.7) Note position of hose fitting (0.6) and

remove hose fitting (0.6).

Change 2

14-14.1/(14.2 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |