|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Fuel Injector Maintenance Instructions (Cont)

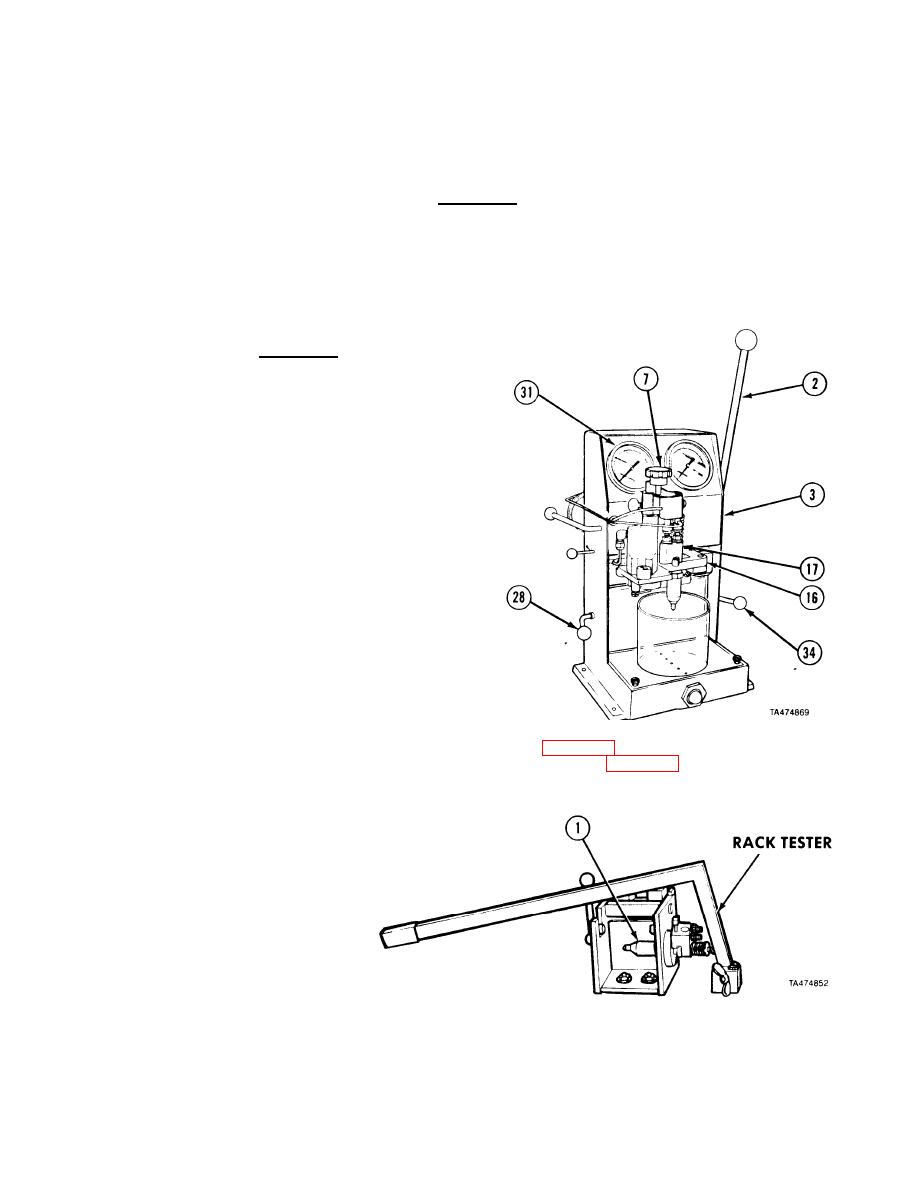

(33) Position pump lever (2) so it points straight up.

(34) Move rocker arm engagement lever (27) to rear.

CAUTION

Do not over tighten control valve or nylon bushing may be damaged.

(35) Close control valve (7).

(36) Pull pump lever (2) forward several times to slowly build up to 1600 to 2000 psi (11032 to

13790 kPa) on left gage (31).

(37) Check for leaks at injector caps (25), body plugs (32), rack (29), and injector nut (33).

(38) Open control valve (7).

CAUTION

Do not over tighten control valve or nylon

bushing may be damaged.

(39) Close control valve (7).

(40) Pull pump lever (2) forward several times

until pressure builds up to 500 psi

(3447.5 kPa) on left gage (31).

(41) Move valve lever (28) so it points forward,

(42) If it takes less than 15 seconds for pressure to

drop from 450 to. 250 psi (3102 to 1723 kPa)

on left gage (31), disassemble injector clean

and reassemble.

(43) Open control valve (7).

(4-4) Move clamp release lever (34) down.

(45) Remove injector (17) and adapter plate (16)

from injector test kit (3).

Testing.

b.

(1) Injectors which pass all tests can be installed (refer to para 12-2).

(2) Injectors which fail one or more tests will be repaired (refer to para 12-3). Perform all injector

tests before repairing injectors.

NOTE

To test injector control rack do

steps (3) through (10).

(3) Install fuel injector (1) in

rack freeness tester.

12-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |