|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

Fig.

Ref.

Point of Measurement

New Dimensions Wear Limits

No.

Letter

(inches)

(inches)

e. Tappet Bore Inside Diameter

g

Valve ................................................................................................ 1.1000 to 1.1010

1.1025

g

Injector ............................................................................................. 1.4000 to 1.4010

1.4025

Out-of-round .....................................................................................

0.0015

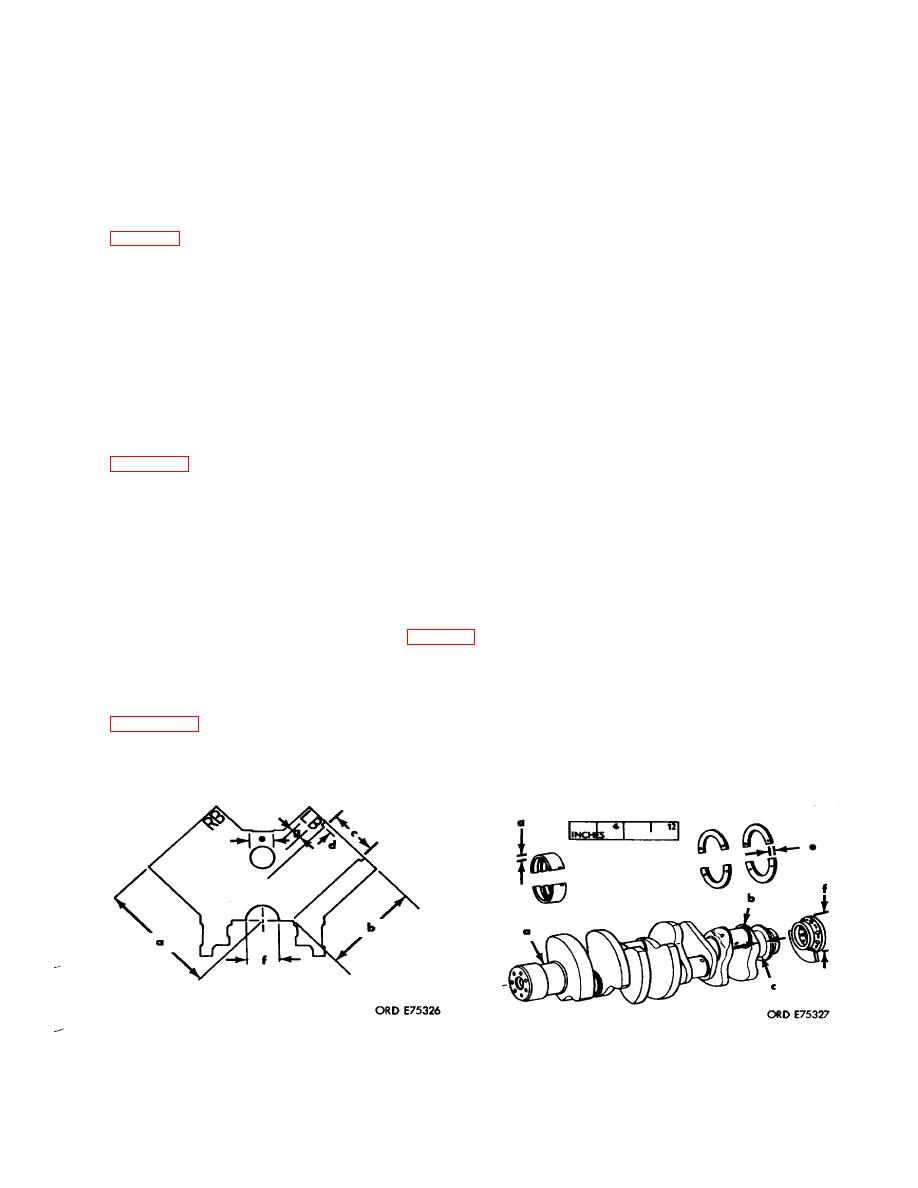

3-176. Crankshaft

a. Crankshaft Journals.

3-103.

a

Diameter of main bearing journals ...........................................

3.4990 to 3.5000

3A.4965

b

Rod journal diameter................................................................

3.1240 to 3.1253

3.1215

c

Rear main (thrust) width...........................................................

1.9400 to 1.9420

1.9440

b. Crankshaft End Clearance.

3-6

Flywheel end of assembled crankshaft ....................................

0.005 to 0.015

0.0220

c. Crankshaft Bearings.

3-103.

d

Main bearing shell thickness ....................................................

0.1245to 0.12525

0.1230

e. Thrust bearing thickness ..........................................................

0.1510 to 0.1530

0.1490

f

Crankshaft adapter outside diameter .......................................

4.749 to 4.751

4.717

3-177. Connecting Rod

a. Measurements.

3-104.

a

Length center to center ............................................................ 8.1920 to 8.1940

b

Inside diameter of connecting rod bore.................................... 3.3160 to 3.3165

3-104

c

Inside diameter of connecting rod bore (piston pin end-in rod)1.9995 to 2.0005

d

Inside diameter of piston pin bushing ...................................... 1.7510 to 1.7515

1.7525

b. Bearing Shell.

3-104.

e

Shell thickness ......................................................................... 0.0942 to 0.0947

0.0929

Journal clearance..................................................................... 0.0015 to 0.0045

0.0070

c. Bore Misalignment. Check on Fixture (Refer to fig. 3-10).

Bend with bushing installed......................................................

0.0040

Twist with bushing installed......................................................

0.0100

3-178. Piston

a. Measurements.

3-105.

a

Outside diameter of piston skirt (at 70sF.) ............................... 5.4870 to .4880

5.4830

b

Piston pin bore inside diameter................................................ 1.7485 to 1.7489

1.7500

c

Piston pin outside diameter...................................................... 1.7488 to 1.7490

1.7478

Figure 3-102. Cylinder block-points of measurement.

Figure 3-103. Crankshaft and bearings-points of

measurement.

3-65

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |